Preparation method of zirconium carbide composite ceramic temperature sensor

A temperature sensor and composite ceramic technology, applied in the field of temperature sensors, can solve the problems of large measurement error and data dispersion, and achieve the effects of long service life, stable electrical performance and non-volatile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

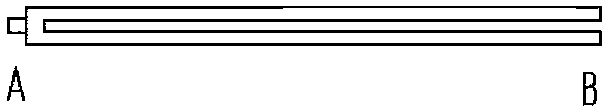

Image

Examples

Embodiment 1

[0017] A preparation method of a zirconium carbide composite ceramic temperature sensor, comprising the following steps:

[0018] (1) According to the volume ratio, take 95% of zirconium carbide powder and 5% of graphite and mix evenly, add ethanol twice the total volume of the mixed powder, put it into a ball mill for ball milling, control the running speed of the ball mill to 150 rpm, and ball mill The time is 40 hours, and the mixture is obtained after ball milling, which is for subsequent use;

[0019] (2) Dry the mixture in a rotary evaporator, control the temperature of the water bath to 65°C, the rotating speed of the rotary bottle to 70 rpm, and the drying time to 2 hours. After drying, pass through a 50-mesh sieve to obtain pre-sintered mixed powder;

[0020] (3) Put the pre-sintered mixed powder into the mold, control the sintering temperature to 2200°C and the pressure to 30MPa in vacuum or inert atmosphere, and carry out hot-press sintering;

[0021] (4) Proc...

Embodiment 2

[0024] A preparation method of a zirconium carbide composite ceramic temperature sensor, comprising the following steps:

[0025] (1) According to the volume ratio, take 85% of zirconium carbide powder and 15% of graphite powder and mix evenly, add ethanol twice the total volume of the mixed powder, put it into a ball mill for ball milling, and control the running speed of the ball mill to 200 rpm / min, the ball milling time was 30 hours, and the mixture was obtained after the ball milling, for subsequent use;

[0026] (2) Dry the mixture in a rotary evaporator, control the temperature of the water bath to 85°C, rotate the bottle at a speed of 20 rpm, and dry for 5 hours. After drying, pass through a 100-mesh sieve to obtain pre-sintered mixed powder;

[0027] (3) Put the pre-sintered mixed powder into the mold, control the sintering temperature to 2100°C and the pressure to 40MPa in vacuum or inert atmosphere, and carry out hot-press sintering;

[0028] (4) Process the ...

Embodiment 3

[0030] A preparation method of a zirconium carbide composite ceramic temperature sensor, comprising the following steps:

[0031] (1) Mix 75% of zirconium carbide powder and 25% of graphite powder according to the volume ratio, add ethanol twice the total volume of the mixed powder, put it into a ball mill for ball milling, and control the running speed of the ball mill to 200 rpm / min, the ball milling time was 30 hours, and the mixture was obtained after the ball milling, for subsequent use;

[0032] (2) Dry the mixture in a rotary evaporator, control the temperature of the water bath to 80°C, rotate the bottle at a speed of 30 rpm, and dry for 4 hours. After drying, pass through a 200-mesh sieve to obtain pre-sintered mixed powder;

[0033] (3) Put the pre-sintered mixed powder into the mold, control the sintering temperature to 2200°C and the pressure to 30MPa in vacuum or inert atmosphere, and carry out hot-press sintering;

[0034] (4) Process the sintered bulk...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com