Modified phenylene sulfide engineering plastic with high tensile strength and preparation method thereof

A high tensile strength, polyphenylene sulfide technology, applied in the field of polymer materials, can solve problems such as inability to achieve, and achieve the effect of overcoming poor toughness, excellent comprehensive mechanical properties, and meeting mechanical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

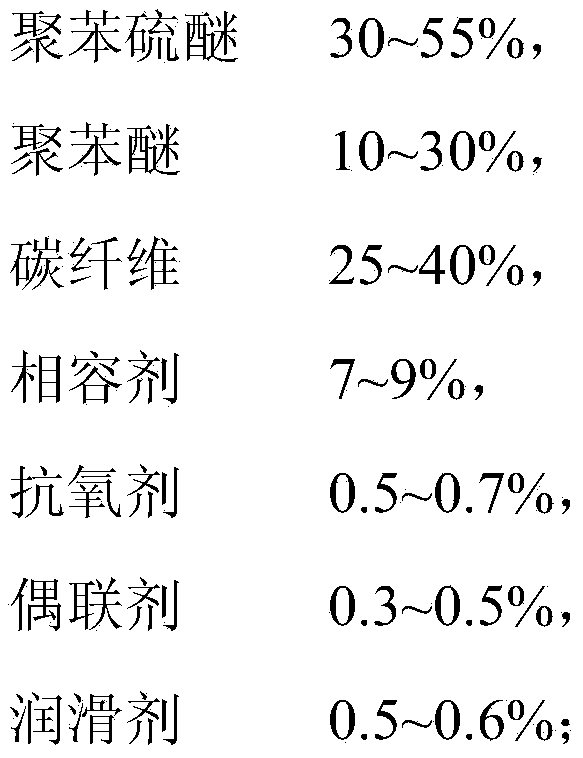

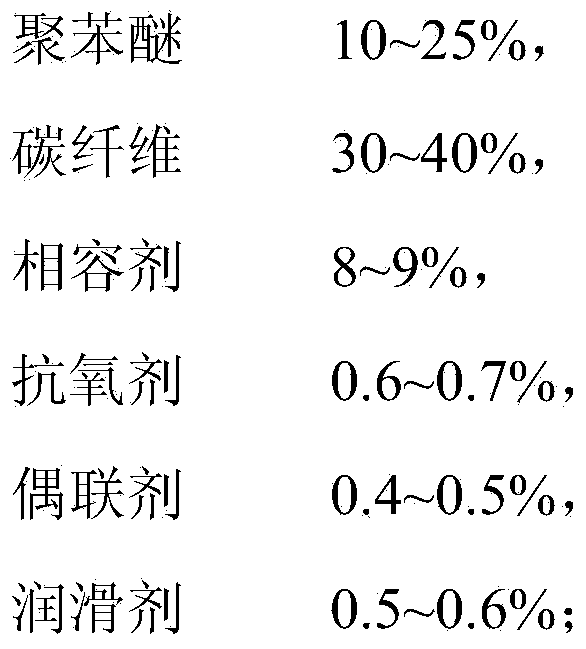

[0025] Weigh the raw materials respectively according to the raw material formulation schemes of each example in Table 1, put the polyphenylene sulfide and polyphenylene ether into the high-speed mixer and pre-mix for 3 to 5 minutes, then add the compatibilizer, antioxidant, coupler Joint agent and lubricant, high-speed mixing for 6-8 minutes; then add pitch-based chopped carbon fiber and low-speed mixing for 8-10 minutes, then melt, knead, extrude, cool, dry, and pelletize through a twin-screw extruder material to obtain the modified polyphenylene sulfide engineering plastics.

[0026] Table 1. Raw materials and weight (kg) used in each embodiment

[0027] components

Example 1

Example 2

Example 3

Example 4

Example 5

Example 6

Example 7

PPS

30

30

40 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com