Water-based protective coating capable of adhering to high temperature billet and preparation method thereof

A protective coating, water-based technology, applied in the direction of sustainable manufacturing/processing, coating, climate sustainability, etc., to reduce heat dissipation, reduce oxidation loss, and improve descaling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

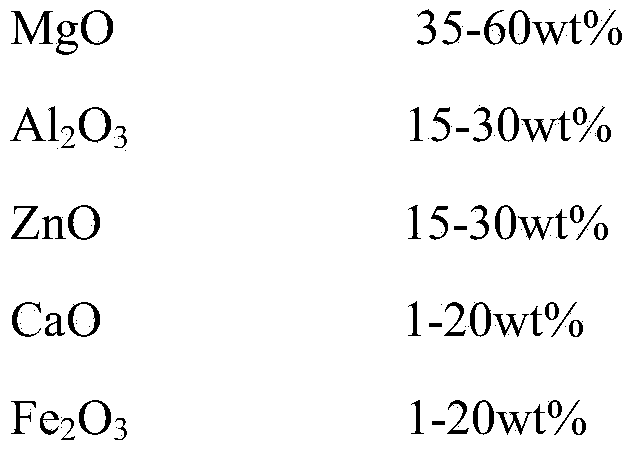

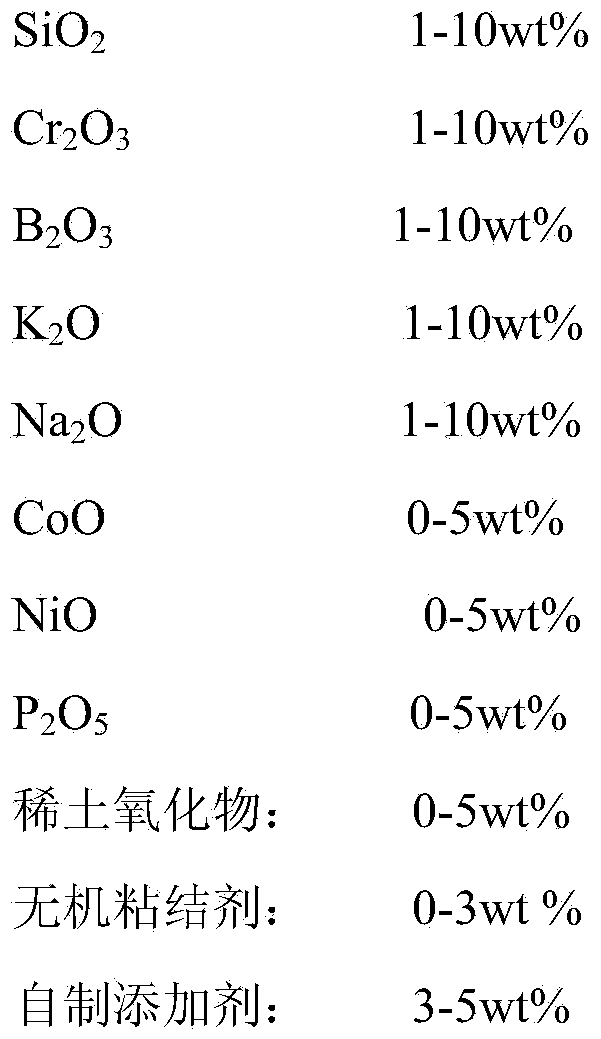

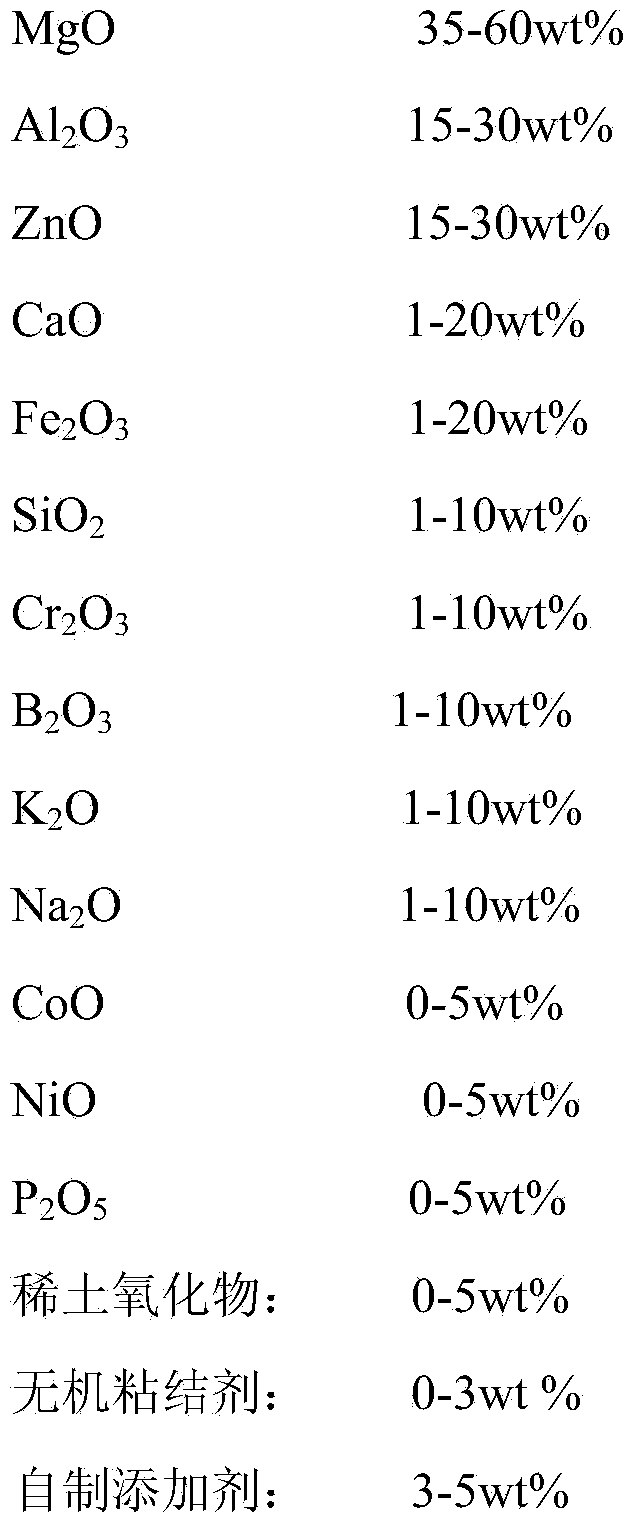

[0030] Clay, magnesite, magnetite and steel slag are mixed according to the chemical composition ratio of dry material: 50wt% MgO, 15wt% Al 2 o 3 , 15wt% ZnO, 5wt% CaO, 5wt% SiO 2 , 2wt% Fe 2 o 3 , 3wt%Na 2 O, 2wt%K 2 O, 3wt% rare earth and other components, and then ball milled to below 300 mesh; the density of the powder is adjusted to 1.45g / cm by adding water 3 ; Sodium carboxydodecylbenzene sulfonate and sodium citrate were put into water according to mass fraction 0.2%, 0.5% and stirred respectively, and then ZnSO was added according to mass fraction 10%, 5% respectively 4, ZnO was added to the previously prepared liquid, and stirred at 60° C. for 3 minutes to form a sol; 5% mass fraction of the sol was added to the above coating to obtain the coating. The paint is sprayed on the surface of the room temperature Q235 billet to form a light yellow protective coating. After leaving the heating furnace, the iron oxide scale is obviously thinned, and the oxidation burni...

Embodiment 2

[0032] Clay, magnesite, diatomite, magnetite and Ni slag are mixed according to the chemical composition ratio of dry material: 40wt% MgO, 15wt% Al 2 o 3 , 20wt% ZnO, 8wt% CaO, 2wt% Fe 2 o 3 , 5wt% SiO 2 , 2wt% NiO, 3wt% Na 2 O, 2wt%K 2 O, 3wt% rare earth and other components, and then ball milled to below 300 mesh; the density of the powder is adjusted to 1.3g / cm by adding water 3 ; Sodium carboxymethyl cellulose and sodium citrate were put into water according to mass fraction 0.2%, 0.5% and stirred respectively, and then ZnO, ZnSO were respectively mixed according to mass fraction 10%, 5%. 4 Add it to the previously prepared liquid, and stir at 70°C for 4 minutes to make a sol; add 4% mass fraction of the sol to the above coating, and finally add 2wt% low-melting glass powder to obtain the coating. The paint is sprayed on the surface of Q235 steel billet at about 700°C to form a light yellow protective coating. After leaving the heating furnace, the iron oxide scale ...

Embodiment 3

[0034] Clay, magnesite, diatomite, magnetite and blast furnace slag are mixed according to the chemical composition ratio of dry material: 35wt% MgO, 12wt% Al 2 o 3 , 30wt% ZnO, 5wt% CaO, 3wt% Fe 2 o 3 , 5wt% SiO 2 , 5wt%Na 2 O, 2wt%K 2 O, 3wt% rare earth and other components, and then ball milled to below 300 mesh; the density of the powder is adjusted to 1.2g / cm by adding water 3 ; Sodium carboxymethyl cellulose and sodium citrate were put into water according to mass fraction 0.2%, 0.5% and stirred respectively, and then ZnO, ZnSO 4 , Zn(OH) 2 Add it to the previously prepared liquid, and stir at 80°C for 5 minutes to make a sol; add 4% mass fraction of the sol to the above coating, and finally add 3wt% low-melting glass powder to obtain the coating. Spray the paint on the surface of Q235 steel billet at about 1050℃ to form a layer of milky white protective coating. After leaving the heating furnace, the iron oxide scale is obviously thinned, and the oxidation burni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com