Preparation method of 4-hydroxybutyric acid test paper resisting interference of ascorbic acid and pigments

A technology for detecting hydroxybutyric acid and test paper, which is applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by making materials undergo chemical reactions, etc., which can solve the instability of normal temperature state, wrong results, interference detection results, etc. problem, to achieve good specificity and sensitivity, eliminate interference, and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

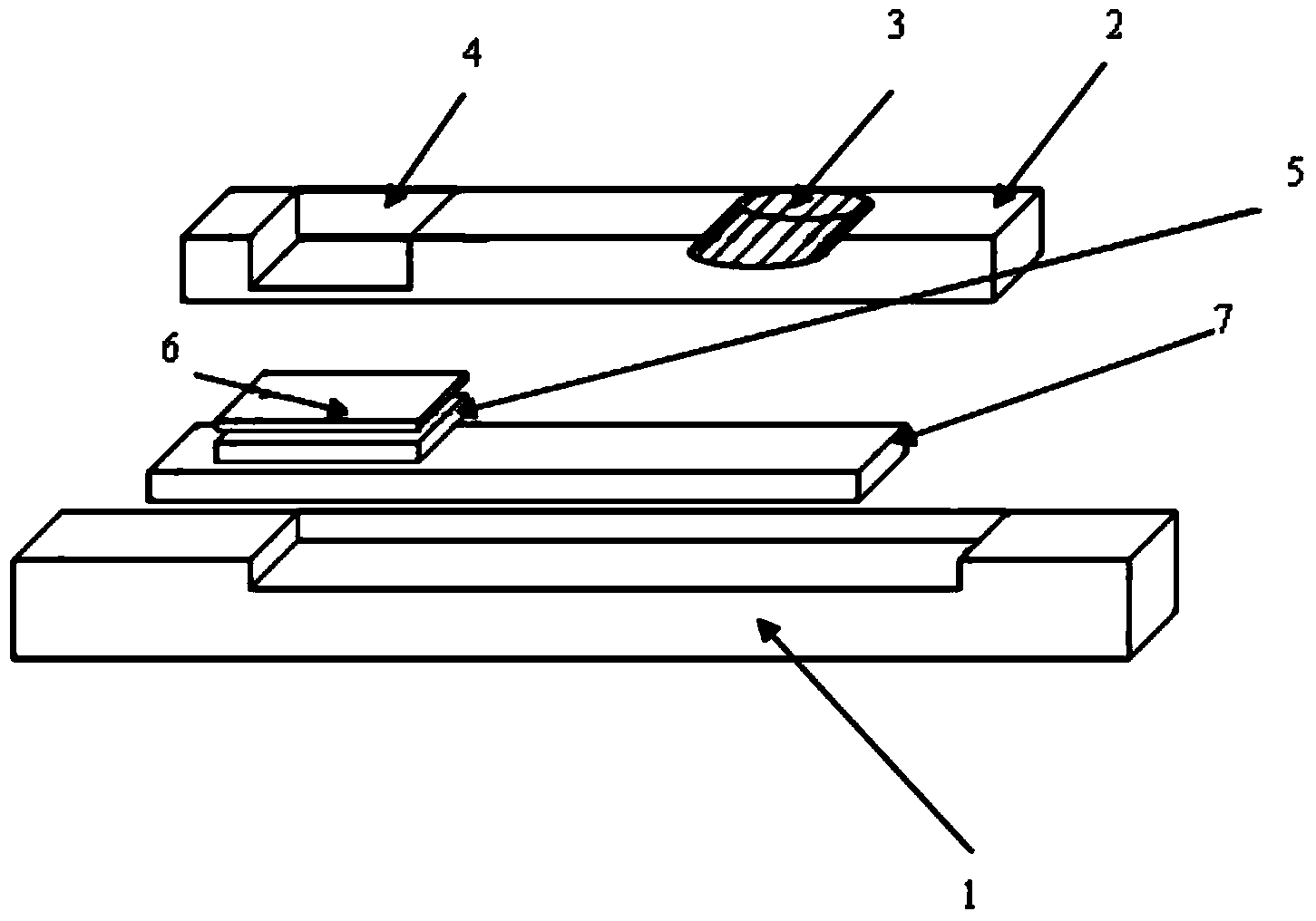

Method used

Image

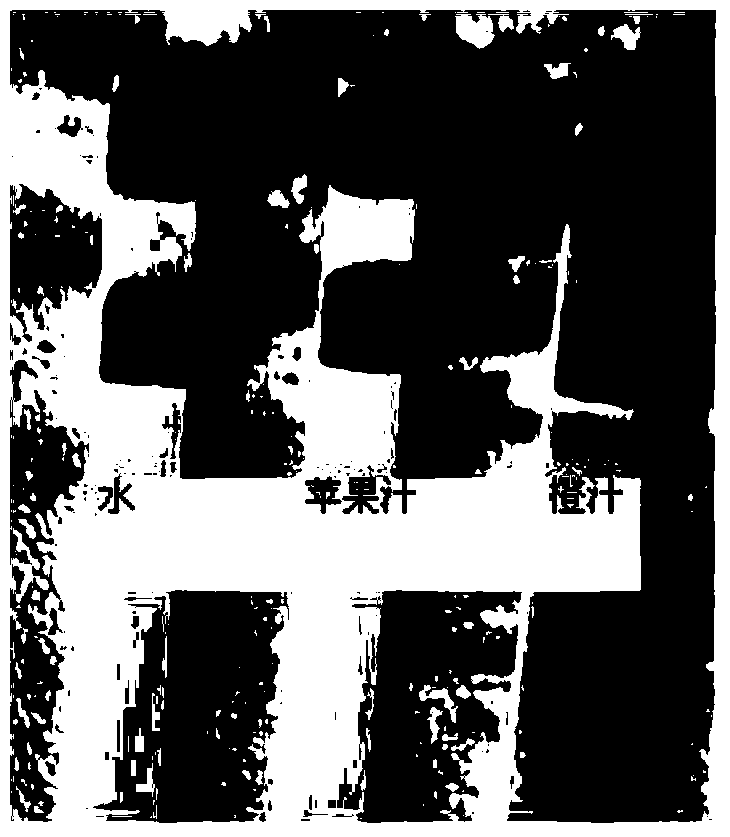

Examples

Embodiment 1

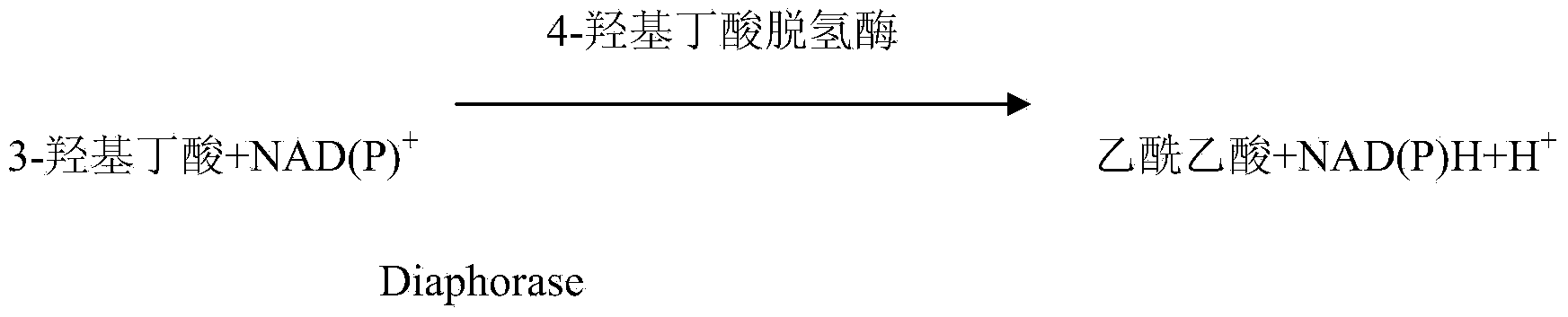

[0034] The preparation process that the total volume of the first phase enzyme solution liquid is 100mL is as follows:

[0035] 1) 50mmol / L Tris-hydrochloric acid buffer with pH 8.0;

[0036] 2) Dissolve 500mg of bovine serum albumin;

[0037] 3) Dissolved into NAD + 0.5g;

[0038] 4) Dissolve diaphorase, 10000iu;

[0039] 5) Dissolve in, 4-hydroxybutyrate dehydrogenase 100000iu.

[0040] The first phase enzyme reagent layer solution impregnation:

[0041] After the solution is prepared, add it to the dipping machine, install a roll of whatman23sl filter paper, set the drying temperature to 50°C, and set the paper speed to 3.0. Start to impregnate and move the paper. After the solution is soaked, the filter paper stays in the drying box for 1 hour to dry completely.

[0042] Preparation of the second phase developer layer solution:

[0043] 100ml of ethanol solution, dissolved in 400mg of nitro blue tetrazolium chloride.

[0044] Second phase solution impregnation:

...

Embodiment 2

[0059] The preparation process that the total volume of the first phase enzyme solution liquid is 100mL is as follows:

[0060] 1) 50mmol / L Tris-hydrochloric acid buffer with pH 8.0;

[0061] 2) Dissolve 500mg of bovine serum albumin;

[0062] 3) Dissolve NAD+0.5g;

[0063] 4) Dissolve diaphorase, 10000iu;

[0064] 5) Dissolve, 4-hydroxybutyrate dehydrogenase 50000iu.

[0065] The first phase enzyme reagent layer solution impregnation:

[0066] After the solution is prepared, add it to the dipping machine, install a roll of whatman23sl filter paper, set the drying temperature to 50°C, and set the paper speed to 3.0. Start to impregnate and move the paper. After the solution is soaked, the filter paper stays in the drying box for 1 hour to dry completely.

[0067] Preparation of the second phase developer layer solution:

[0068] 100ml of ethanol solution, dissolved in 300mg of nitro blue tetrazolium chloride

[0069] Second phase solution impregnation:

[0070] The 593...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com