Preparation method for zinc oxide thin-film transistor

A technology of thin film transistor and zinc oxide, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of high manufacturing cost, rare content, unenvironmental protection, etc., and achieve low manufacturing cost, improved performance, uniformity, etc. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below by specific examples.

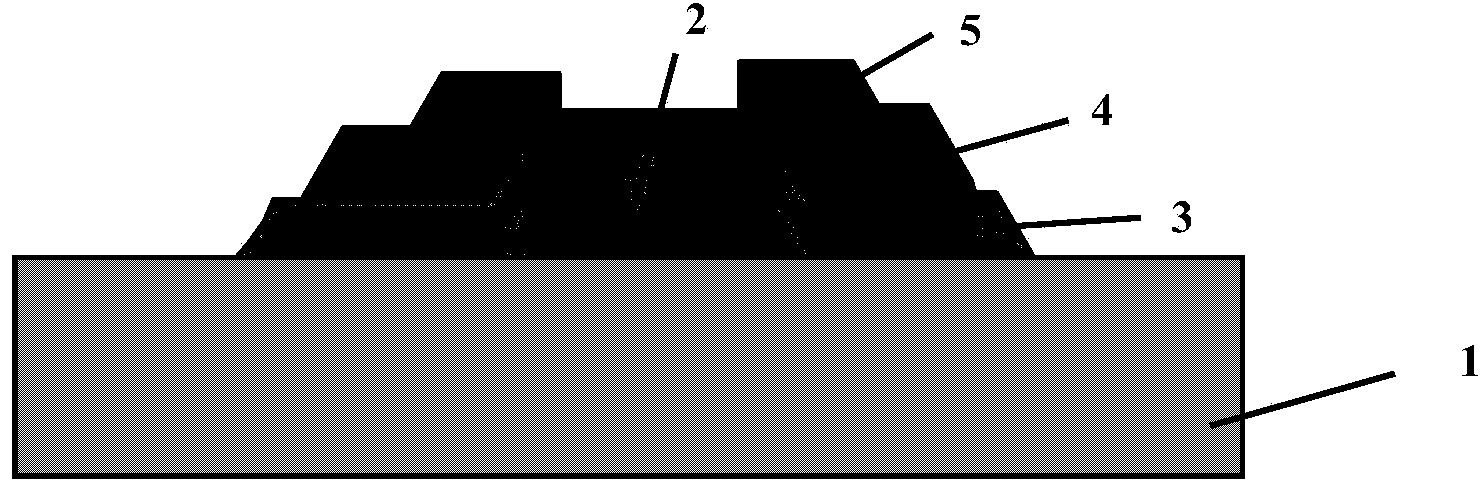

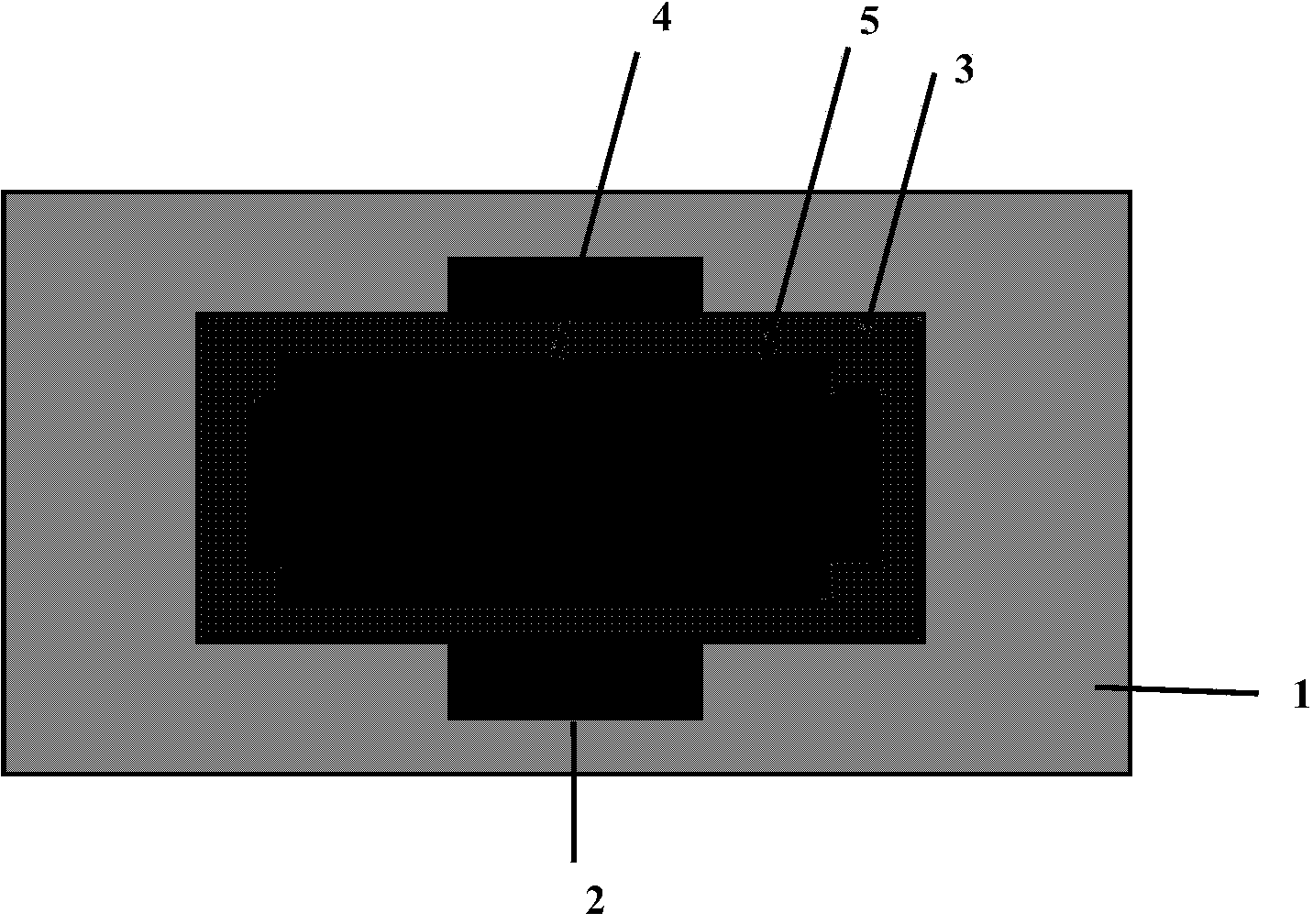

[0029] The concrete example of the manufacturing method of the thin film transistor of the present invention is by Figure 3(a) to Figure 3(e) shown, including the following steps:

[0030] As shown in FIG. 3( a ), the substrate is a transparent glass or plastic substrate substrate 1 .

[0031] As shown in FIG. 3( b ), a 30-150 nanometer thick ITO conductive film is grown on the substrate 1 by magnetron sputtering technology, and then the gate electrode is etched by photolithography.

[0032] As shown in FIG. 3( c ), a silicon dioxide insulating layer with a thickness of 50-250 nanometers is grown by PECVD, and then photolithography is used to form a gate dielectric.

[0033] As shown in FIG. 3( d ), a nickel-doped zinc oxide semiconductor material channel layer is grown by a sputtering process. The target used for sputtering is nickel-doped zinc oxide ceramic target, the content of nickel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com