Preparation method of fotemustine

A formustine and reaction medium technology, applied in the field of medicinal chemistry, can solve the problems of low product purity and low yield, and achieve the effects of high purity, high yield and suitability for industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention provides a preparation method of formustine, which comprises the following steps:

[0028] a) 1-aminoethyl diethyl phosphate and carmustine undergo amination reaction in the reaction medium to obtain the compound represented by formula (II); the reaction medium includes water;

[0029] b) The compound represented by formula (II) is subjected to nitrosation and converted into formustine;

[0030]

[0031] The present invention uses 1-aminoethyl diethyl phosphate and carmustine as raw materials, wherein the structural formula of 1-aminoethyl diethyl phosphate is:

[0032]

[0033] The chemical name of carmustine is: 1,3-bis(2-chloroethyl)-1-urea nitrite, and the structural formula is:

[0034]

[0035] The diethyl 1-aminoethyl phosphate and carmustine described in the present invention are raw materials well known to those skilled in the art, and the present invention has no particular limitation on this. The molar ratio of the diethyl 1-aminoethyl phosphate ...

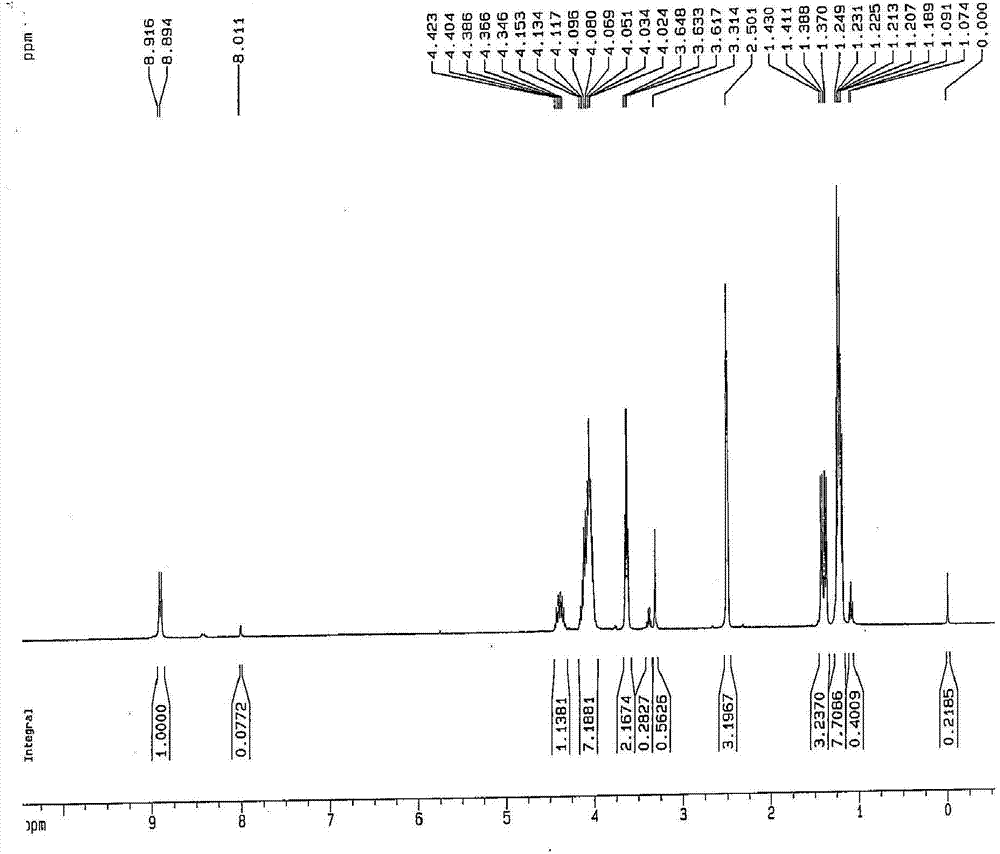

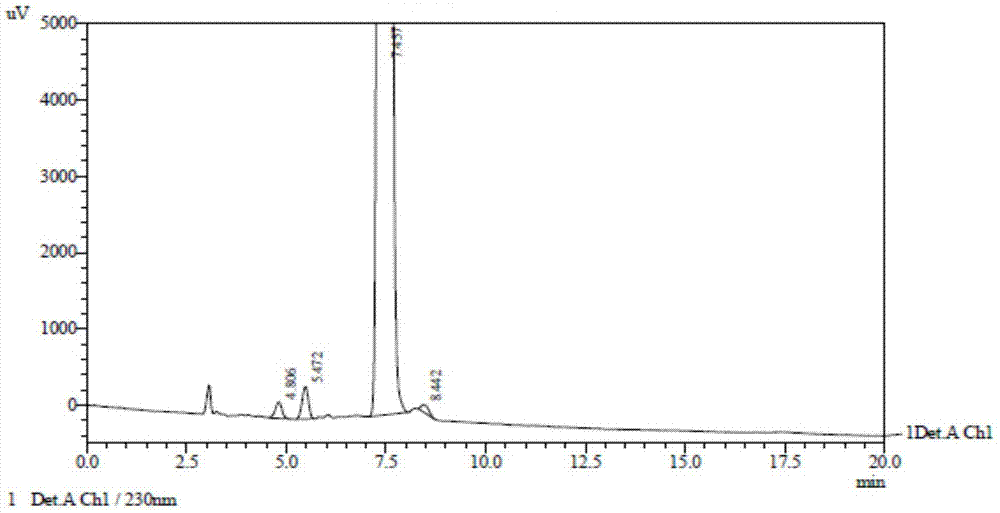

Embodiment 1

[0045] (1) Put 5.10g (0.0279mol) of diethyl 1-aminoethyl phosphate in a 50mL reaction flask, add 4.68mL of purified water, and then add 2.0g (0.0093mol) of carmustine at room temperature. Reacted for 2h, then cooled to room temperature, washed with 10% dilute hydrochloric acid, extracted with dichloromethane, dried, evaporated to dryness under reduced pressure, washed with 20mL purified water, extracted with dichloromethane (3×20mL), and combined the extracts. The reaction product is obtained by drying with sodium sulfate, filtering, and evaporating to dryness under reduced pressure.

[0046] (2) Add 8.0 mL of formic acid to the reaction product obtained in the above steps, maintain the reaction temperature at 0℃~5℃, add 1.4g (3mol) of sodium nitrite in batches, need 1.5h to complete, and carry out nitrosation for 0.5h , Then evaporate the formic acid under reduced pressure at less than 35°C. The residue was dissolved in 20 mL of dichloromethane, washed with purified water (20 mL...

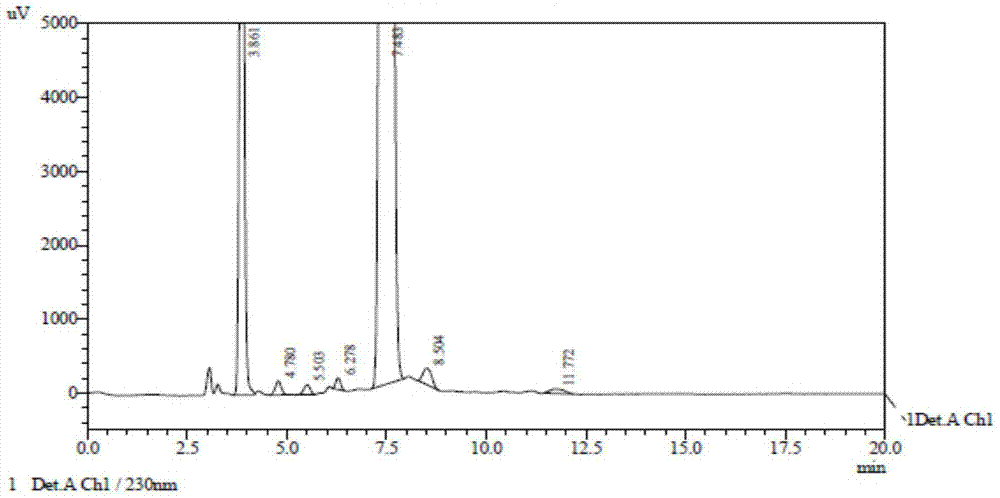

Embodiment 2

[0049] (1) Put 3.98g (0.0186mol) of diethyl 1-aminoethyl phosphate in a 50mL reaction flask, add 4.68mL of purified water, and then add 2.0g (0.0093mol) of carmustine at room temperature. Reacted for 2h, then cooled to room temperature, washed with 10% dilute hydrochloric acid, extracted with dichloromethane, dried, evaporated to dryness under reduced pressure, washed with 20mL purified water, extracted with dichloromethane (3×20mL), and combined the extracts. The reaction product is obtained by drying with sodium sulfate, filtering, and evaporating to dryness under reduced pressure.

[0050] (2) Add 8.0 mL of formic acid to the reaction product obtained in the above steps, maintain the reaction temperature at 0℃~5℃, add 1.4g (3mol) of sodium nitrite in batches, need 1.5h to complete, and carry out nitrosation for 0.5h , Then evaporate the formic acid under reduced pressure at less than 35°C. The residue was dissolved in 20 mL of dichloromethane, washed with purified water (20 mL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com