Polycarbonate composite material and preparation method thereof

A composite material and polycarbonate technology, which is applied in the field of polycarbonate composite material and its preparation, can solve the problems of poor strength and folding resistance of aluminum foil, difficult to meet the needs of packaging aesthetics, and no environmental protection characteristics, and achieves protection. The effect of no scratches, good tensile properties, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Weigh 55 kg of trimethylene carbonate, 10 kg of silicon dioxide with a diameter of 80 nanometers, 8 kg of glycerol and 2 kg of glutaraldehyde, mix evenly, adjust the pH to 8.2, and place it in a nitrogen atmosphere at 0.5 atm at 110 °C, Stir for 3 hours at a stirring rate of 250 rpm, cool to room temperature, and set aside;

[0028] (2) Adjust the pH of the product in step 1 to 7, add 10kg of glyceryl tristearate, 17kg of hydroxyethyl methacrylate and 20kg of polyethylene glycol with an average molecular weight of 8000, add it to a three-blade screw machine, and stir evenly , to obtain polycarbonate composites.

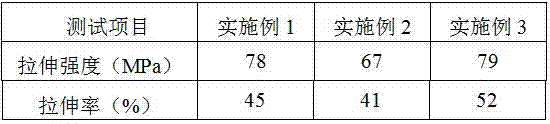

[0029] The polycarbonate composite material is made into a length of 10cm, a width of 1cm, and a thickness of 2mm. The performance test results are shown in Table 1.

Embodiment 2

[0031] (1) Weigh 70 kg of trimethylene carbonate, 20 kg of silicon dioxide with a diameter of 70 nanometers, 7 kg of glycerol and 3 kg of glutaraldehyde, mix evenly, adjust the pH to 8.2, and place it in a nitrogen atmosphere at 0.5 atm at 120 ° C. Stir for 5 hours at a stirring rate of 200 rpm, cool to room temperature, and set aside;

[0032] (2) Adjust the pH of the product in step 1 to 7, add 15kg of glyceryl tristearate, 20kg of hydroxyethyl methacrylate and 18kg of polyethylene glycol with an average molecular weight of 7000, add it to a three-blade screw machine, and stir evenly , to obtain polycarbonate composites.

[0033] The polycarbonate composite material is made into a length of 10cm, a width of 1cm, and a thickness of 2mm. The performance test results are shown in Table 1.

Embodiment 3

[0035] (1) Weigh 60kg of trimethylene carbonate, 16kg of silicon dioxide with a diameter of 50nm, 5kg of glycerol and 5kg of glutaraldehyde, mix evenly, adjust the pH to 8.2, and place it in a nitrogen atmosphere at 0.5atm110°C, Stir for 4 hours at a stirring rate of 250 rpm, cool to room temperature, and set aside;

[0036] (2) Adjust the pH of the product in step 1 to 7, add 12kg of glyceryl tristearate, 15kg of hydroxyethyl methacrylate and 15kg of polyethylene glycol with an average molecular weight of 6000, add it to a three-blade screw machine, and stir evenly , to obtain polycarbonate composites.

[0037] The polycarbonate composite material is made into a length of 10cm, a width of 1cm, and a thickness of 2mm. The performance test results are shown in Table 1.

[0038] Table 1

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com