Cleaning Fluid Additive for Polysilicon Chain Texturing Equipment and Its Application

A technology of cleaning liquid and polysilicon, which is applied in detergent composition, soap detergent composition, organic detergent composition, etc., can solve the problems of large amount of hydrofluoric acid, difficult removal, and long time consumption, and achieve high surface activity and Effects of stability, surface dirt reduction, and strong penetrating ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A preparation method of the cleaning solution of polysilicon chain type texturing equipment adopts the following process steps:

[0016] 1) Configure texturing additives: add 0.01g of fluorocarbon surfactant, 0.5g of sodium dodecylbenzenesulfonate, and 0.1g of hydroxyethyl cellulose into deionized water to obtain 100g of cleaning solution for polysilicon chain texturing equipment Additive solution.

[0017] 2) Configure cleaning solution: Dissolve 100g of NaOH in deionized water to obtain 20kg of alkali solution; dissolve 100g of cleaning solution additives made in step 1) in alkali solution to obtain cleaning solution for polysilicon chain texturing equipment .

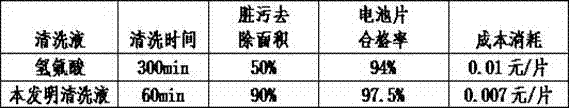

[0018] During the experiment in this embodiment, the configured cleaning fluid was used to soak and clean the cleaning tank, positioning roller, and transmission roller for about 50 minutes. The test results are shown in Table 1.

[0019] Table 1

[0020]

Embodiment 2

[0022] A preparation method of the cleaning solution of polysilicon chain type texturing equipment adopts the following process steps:

[0023] 1) Configure texturing additives: add 1g fluorocarbon surfactant, 20g sodium dodecylbenzenesulfonate, and 10g hydroxyethyl cellulose into deionized water to obtain 1kg polysilicon chain type texturing equipment cleaning solution additive solution.

[0024] 2) Configure cleaning solution: Dissolve 600g of NaOH in deionized water to obtain 20kg of alkali solution; dissolve 1kg of cleaning solution additives made in step 1) in alkali solution to obtain a cleaning solution for polysilicon chain texturing equipment .

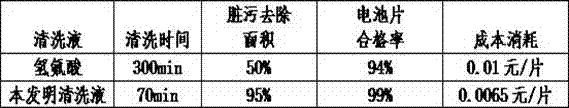

[0025] During the experiment in this embodiment, the configured cleaning fluid was used to soak and clean the cleaning tank, positioning roller, and transmission roller for 60 minutes. The test results are shown in Table 2.

[0026] Table 2

[0027]

Embodiment 3

[0029] A preparation method of the cleaning solution of polysilicon chain type texturing equipment adopts the following process steps:

[0030] 1) Configure texturing additives: add 0.3g fluorocarbon surfactant, 6g sodium dodecylbenzenesulfonate and 3g hydroxyethyl cellulose into deionized water to obtain 600g polysilicon chain type texturing equipment cleaning solution additive solution .

[0031] 2) Configure cleaning solution: Dissolve 400g of NaOH in deionized water to obtain 20kg of alkali solution; dissolve 600g of cleaning solution additives made in step 1) in alkali solution to obtain a cleaning solution for polysilicon chain type texturing equipment .

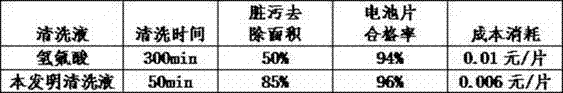

[0032] During the experiment in this embodiment, the configured cleaning solution was used to soak and clean the cleaning tank, positioning roller, and transmission roller for 70 minutes. The test results are shown in Table 3.

[0033] table 3

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com