Cellulose triacetate aerogel and preparation method

A technology of cellulose triacetate and airgel, which is applied in the field of cellulose triacetate airgel and its preparation, can solve the problems of high airgel density, long preparation cycle, and large amount of solvent, and achieve high specific surface area, The effect of short preparation cycle and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 10g of cellulose triacetate into a flask, add 50ml of 1,4-dioxane, heat to 70°C in an oil bath while applying condensing reflux, and magnetically stir for about 2 hours to obtain a colorless, transparent and clear solution. Then, 50 ml of isopropanol was added dropwise thereto under the state of heating, stirring and condensing and reflux to obtain a colorless, transparent and clear solution. Pour the solution into a mold, seal it and let it stand and cool naturally to 20°C for about 20 hours to obtain a transparent triacetate cellulose gel. The 1,4-dioxane and isopropanol solvents in the gel were removed by supercritical carbon dioxide drying technology, and then the mold was removed to obtain a translucent cellulose triacetate airgel sample with a shape given by the mold, with a density of 103.8mg / cm 3 .

Embodiment 2

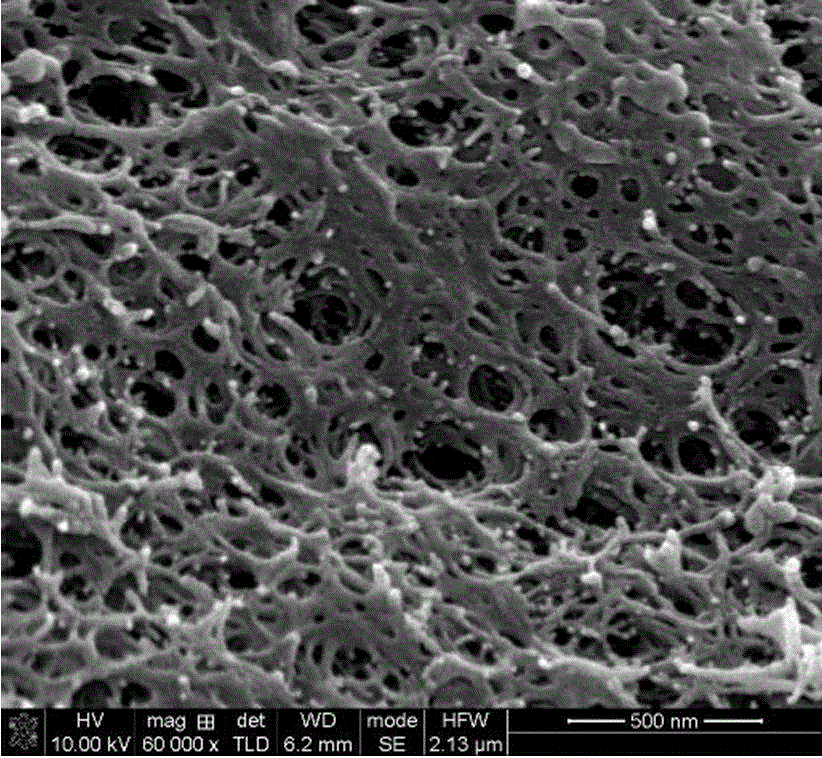

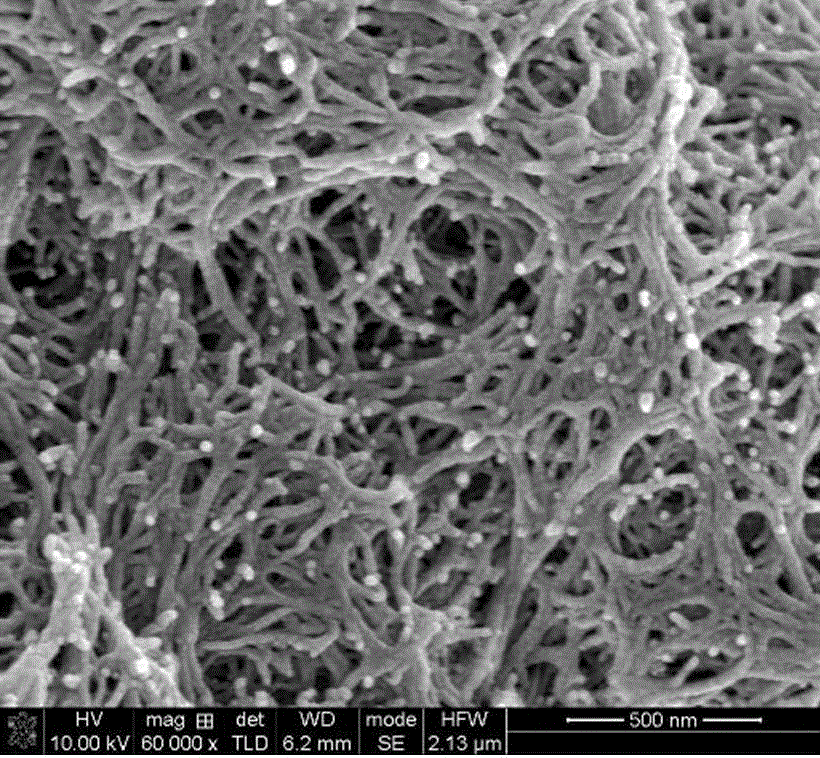

[0029] Weigh 5g of cellulose triacetate into a flask, add 50ml of 1,4-dioxane, heat to 70°C in an oil bath while applying condensing reflux, and magnetically stir for about 2 hours to obtain a colorless, transparent and clear solution. Then, 50 ml of isopropanol was added dropwise thereto under the state of heating, stirring and condensing and reflux to obtain a colorless, transparent and clear solution. Pour the solution into a mold, seal it and let it stand and cool it naturally to 10°C for about 20 hours to obtain a transparent triacetate cellulose gel. The 1,4-dioxane and isopropanol solvents in the gel were removed by supercritical carbon dioxide drying technology, and then the mold was removed to obtain a translucent cellulose triacetate airgel sample with the shape given by the mold. figure 1 From the scanning electron micrographs of the cellulose triacetate airgel prepared for this example, it can be seen that the airgel has a nanoscale microporous structure with a por...

Embodiment 3

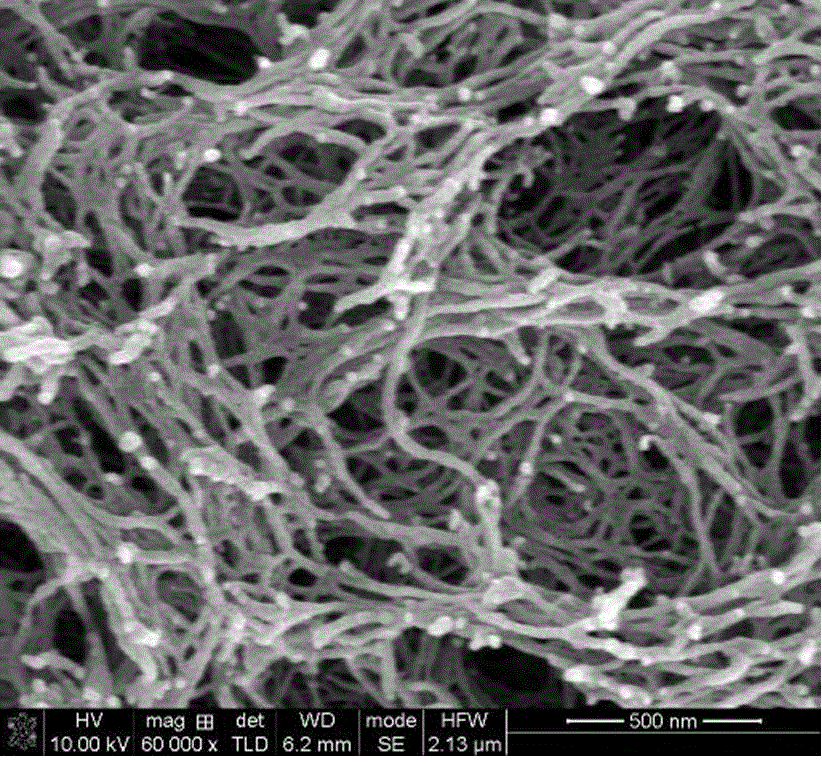

[0031] Weigh 2.5g of cellulose triacetate into a flask, add 50ml of 1,4-dioxane, heat to 70°C in an oil bath while applying condensing reflux, and magnetically stir for about 2 hours to obtain a colorless, transparent and clear solution , and then under the state of heating, stirring and condensing and reflux, 50ml of isopropanol was added dropwise thereto to obtain a colorless, transparent and clear solution. Pour the solution into a mold, seal it and let it stand and cool naturally to 20°C for about 30 hours to obtain a transparent triacetate cellulose gel. The 1,4-dioxane and isopropanol solvents in the gel were removed by supercritical carbon dioxide drying technology, and then the mold was removed to obtain a translucent cellulose triacetate airgel sample with the shape given by the mold. figure 2 The scanning electron micrograph of the cellulose triacetate airgel prepared for this example shows that the airgel has a three-dimensional nanostructure formed by interlacing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com