Method for Enriching Long-chain Polyunsaturated Fatty Acids Using Immobilized Thermomyces lanuginosus Lipase

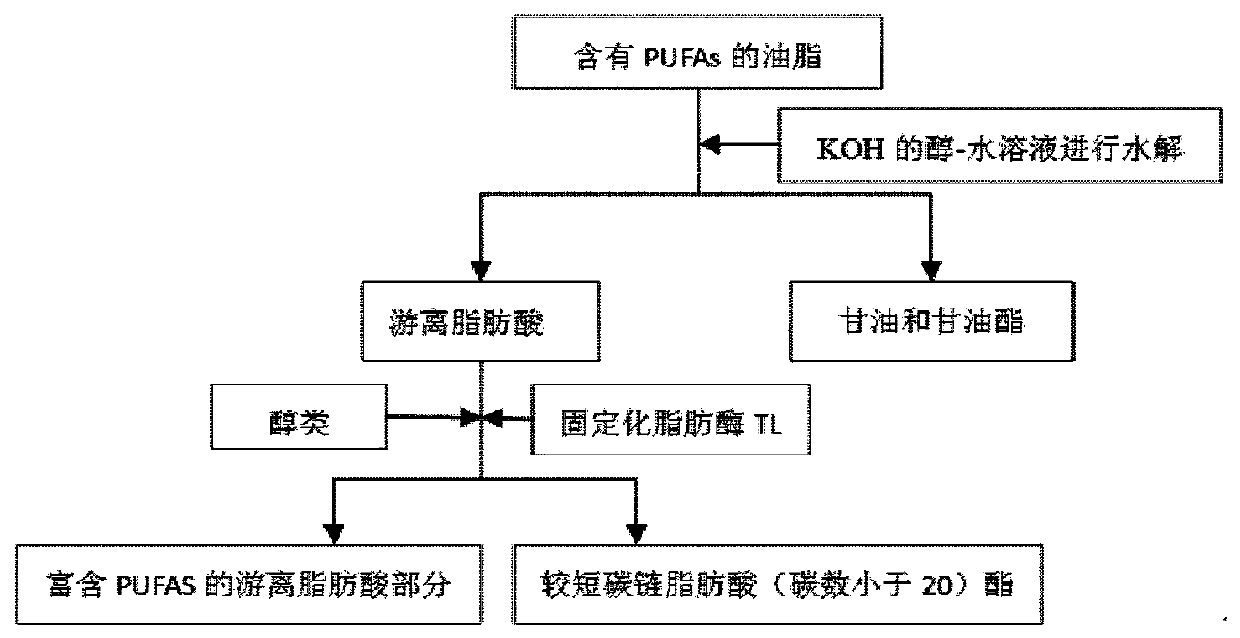

A technology for immobilizing lipase and unsaturated fatty acids, which is used in the production of fat, fat oil/fat separation, fermentation, etc., can solve the problems of inability to meet the market demand for high-content ω-3 PUFAs, difficult hydrolysis reaction process, and low enrichment effect. , to achieve the effect of low price, reducing the use of organic reagents and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1D

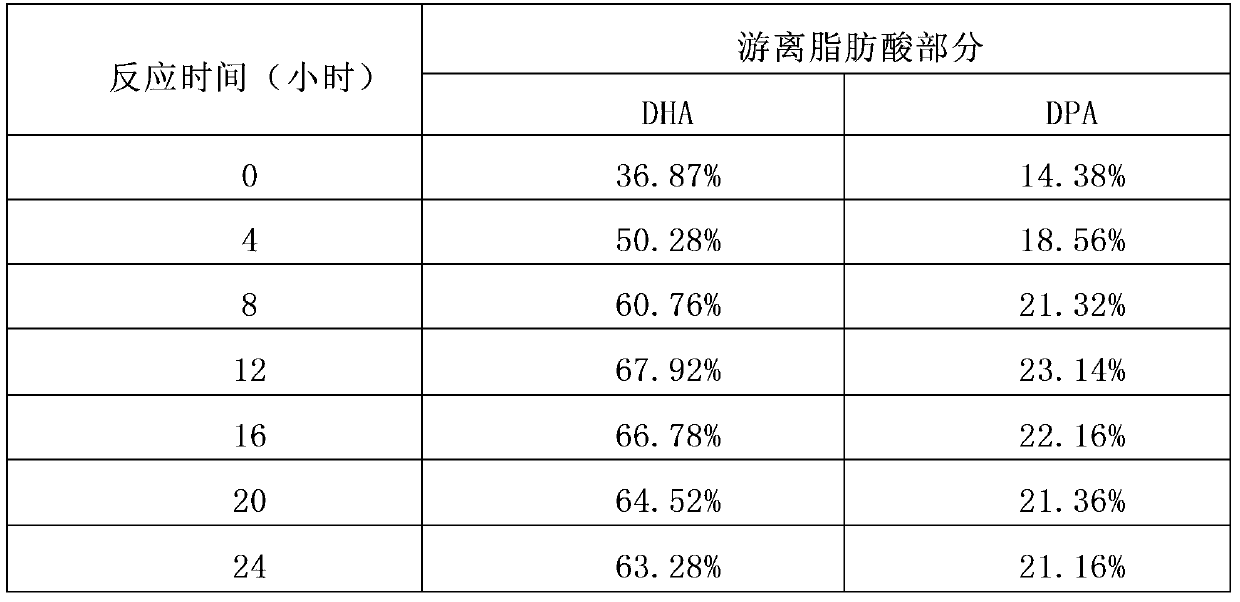

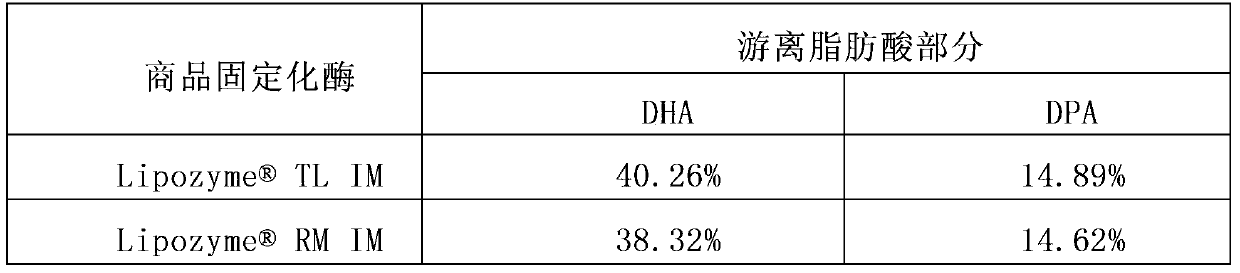

[0071]Enrichment and purification of PUFAs in embodiment 1DHA algae oil

[0072] (1) Alkali-catalyzed hydrolysis: First, dissolve 36.8g KOH in 70.4mL water and 422.4mL95% ethanol to prepare KOH alcohol-water solution, add 160g DHA algae oil under nitrogen protection, and reflux for 1 hour under magnetic stirring at 50°C. Hydrolyze fats. After the reaction, add 381mL of water, extract the unsaponifiable matter with 500mL×2 n-hexane, acidify the hydrated layer with 3N HCl to pH=1, extract the free fatty acid with 300mL×2 n-hexane, and then use anhydrous Na 2 SO 4 After drying, the solvent was removed by rotary evaporation to obtain free fatty acid.

[0073] (2) Weigh 9.57g of free fatty acid prepared in step (1) and 3g of glycerol (the molar ratio of free fatty acid and glycerol is about 1:1) into a 50mL reactor, add 10% immobilized TL lipase (to react Substrate (that is, the total mass of free fatty acid and glycerol) by mass), reacted at a stirring rate of 250rpm under vacu...

Embodiment 3

[0089] Enrichment and purification of PUFAs in embodiment 3 sardine oil

[0090] (1) Alkali-catalyzed hydrolysis: First, dissolve 18g KOH in 35mL water and 210mL 95% ethanol to prepare KOH alcohol-water solution, add 70g sardine oil under the protection of argon, and reflux for 0.5 hours under magnetic stirring at 60°C to hydrolyze the oil. After the reaction, add 200mL of water, extract the unsaponifiable matter with 200mL×2 n-hexane, and use 3N HNO 3 Acidify to pH=1, extract free fatty acids with 200mL×2 n-hexane, and then use anhydrous MgSO 4 After drying, the solvent was removed by rotary evaporation to obtain free fatty acid.

[0091] (2) Weigh 9.75g of 7 parts of free fatty acid prepared in step (1), and place them in a 50mL reactor with lauryl alcohol (the molar ratio of free acid and lauryl alcohol is shown in Table 4), and add 10% immobilized TL lipase (Based on the mass of the reaction substrate), the reaction was carried out at a stirring rate of 250 rpm for 12 ho...

Embodiment 4

[0095] Enrichment and purification of PUFAs in cod liver oil of embodiment 4

[0096] (1) Alkali-catalyzed hydrolysis: First, 26.3g NaOH was dissolved in 70.4mL water and 422.4mL95% ethanol to prepare KOH alcohol-water solution. Under nitrogen protection, 150g cod liver oil was added and refluxed for 1.5 hours under magnetic stirring at 65°C to make the oil hydrolysis. After the reaction, add 381mL of water, extract the unsaponifiable matter with 500mL×2 n-hexane, acidify the hydrated layer to pH=1 with 3N HCL, extract the free fatty acid with 300mL×2 n-hexane, and then use anhydrous CuSO 4 After drying, the solvent was removed by rotary evaporation to obtain free fatty acid.

[0097] (2) Weigh 7 parts of 9.70g of free fatty acid prepared in step (1) (produced by alkali-catalyzed hydrolysis of cod liver oil), and 3g of glycerin (the molar ratio of free acid to glycerin is about 1:1) in a 50mL reactor Inside, add immobilized TL lipase (based on the mass of the reaction substr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of unsaturation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com