Polyacrylic acid (SALT) water-absorbing resin and manufacturing method therefor

A manufacturing method and technology of polyacrylic acid, which can be applied in the direction of absorbent pads, bandages, medical science, etc., can solve the problems of acrylic acid costing huge labor and cost, increasing the unpleasant smell of water-absorbing resin, and restricting production scale, etc., to achieve excellent physical properties, Effects of odor reduction and purification cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

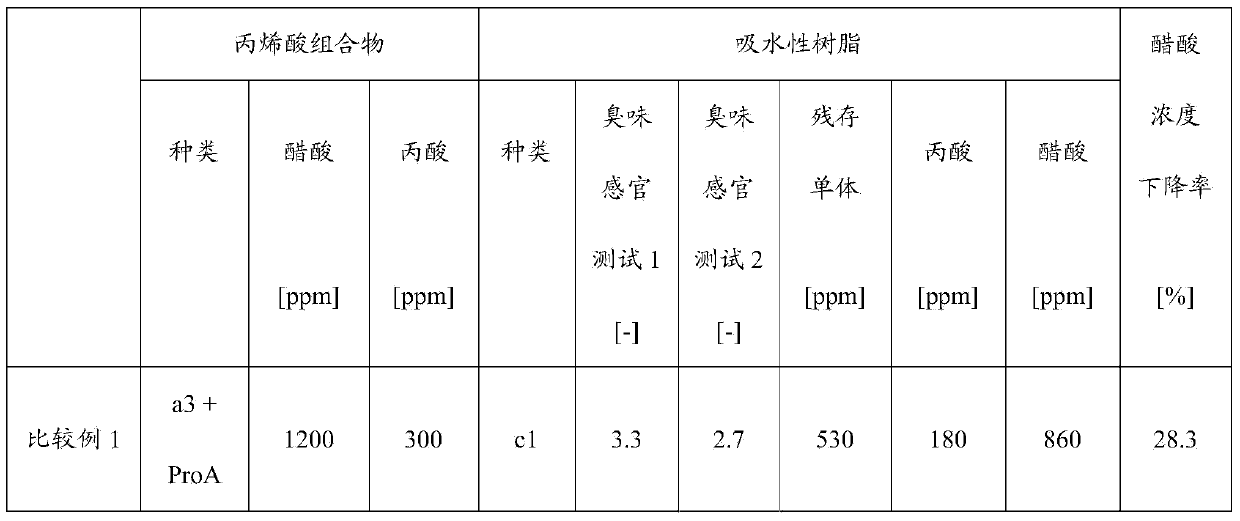

[0461] The present invention will be described more specifically based on the following examples and comparative examples, but the present invention is not limited to these examples, and examples obtained by appropriately combining technical features disclosed in the respective examples are also included in the present invention. In the range.

[0462] In addition, for simplicity, "liter" is expressed as "l" or "L", and "weight%" is expressed as "wt%". Furthermore, in the determination of trace components, the detection limit is denoted as N.D (Non Detected).

[0463] In addition, unless otherwise noted, the electronic equipment (including the measurement of the physical properties of the water-absorbent resin) used in the production examples, examples, and comparative examples used a power supply of 200V or 100V. In addition, unless otherwise noted, the various physical properties of the water-absorbent resin of the present invention were measured under conditions of room te...

manufacture example 1

[0513] Gaseous acrylic acid obtained by contacting gas-phase propylene oxide was collected with water to continuously obtain a 70% by weight aqueous solution of acrylic acid. Then, toluene was supplied from the top of a distillation tower (azeotropic dehydration tower) having 50 non-weir perforated plates, and the aqueous acrylic acid solution was supplied from the middle of the distillation tower, and azeotropic dehydration distillation was performed to obtain crude acrylic acid from the bottom of the tower. .

[0514] Then, the crude acrylic acid was continuously supplied to the bottom of a distillation tower (high-boiling-point impurity separation tower) having 50 perforated plates without weirs, and distillation was performed at a reflux ratio of 1. Then, after refining by redistillation, the polymerization inhibitor p-methoxyphenol was added, and the acrylic composition (a1) whose purity was 99 weight% or more was obtained.

[0515] In addition, as impurities in the acry...

manufacture example 2

[0517] Except that the number of weir-free perforated plates in the azeotropic dehydration tower of Production Example 1 was changed from 50 to 45, the same operation as in Production Example 1 was carried out to obtain an acrylic acid composition (a2) with a purity of 99% by weight or more. ).

[0518] As impurities in the acrylic composition (a2), acetic acid is 1800ppm, propionic acid is 400ppm, acrylic acid dimer is 110ppm, and protopulsatin (PAN) and aldehyde components are N.D (below the detection limit / below 1ppm). In addition, the content of p-methoxyphenol was 70 ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com