Method for improving microalgae growth rate and oil yield

A growth rate and microalgae technology, which is applied in the field of improving the growth rate and oil yield of microalgae, can solve the problem that single-gene knockout mutants cannot grow normally, and achieve the effects of improving growth rate, high efficiency and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

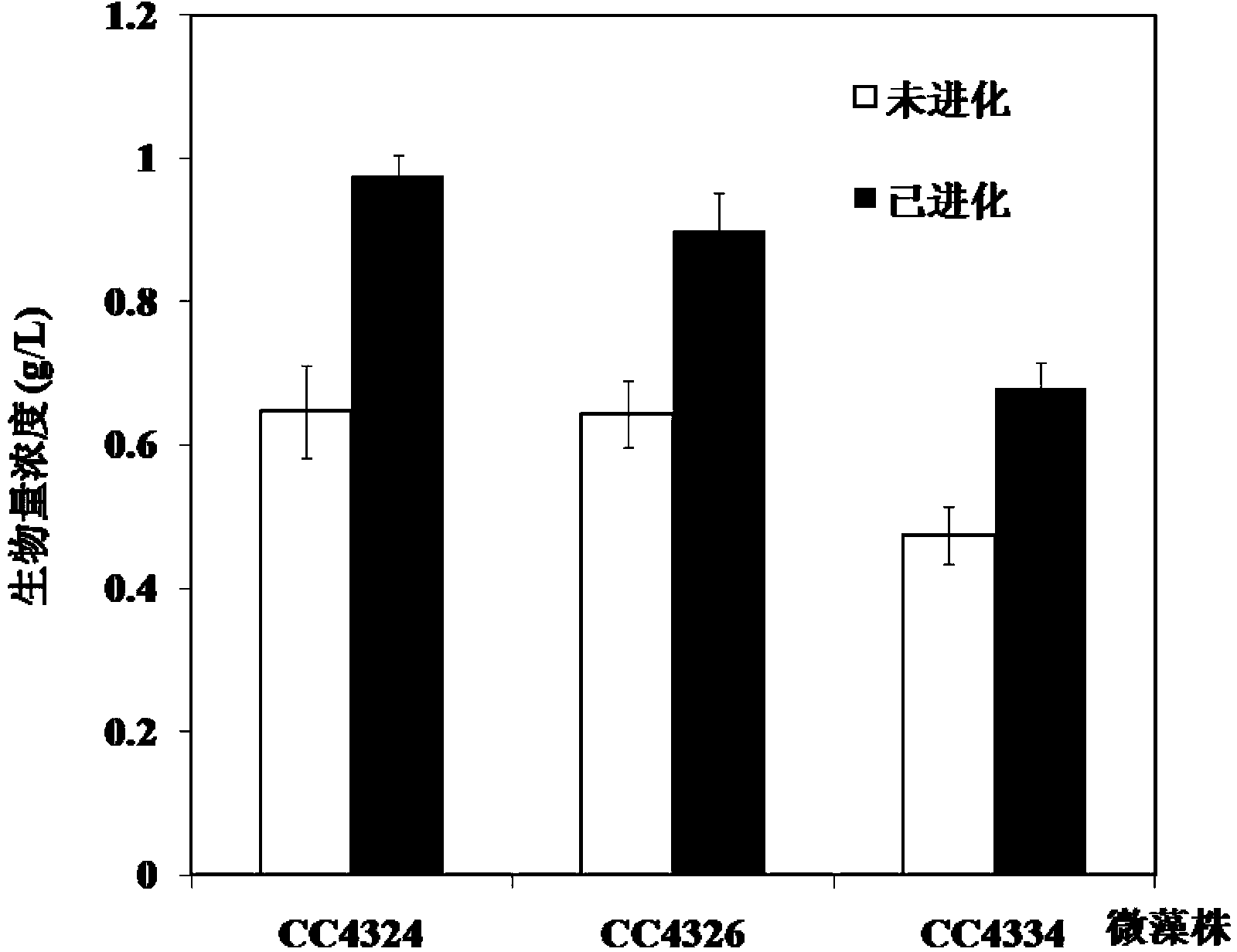

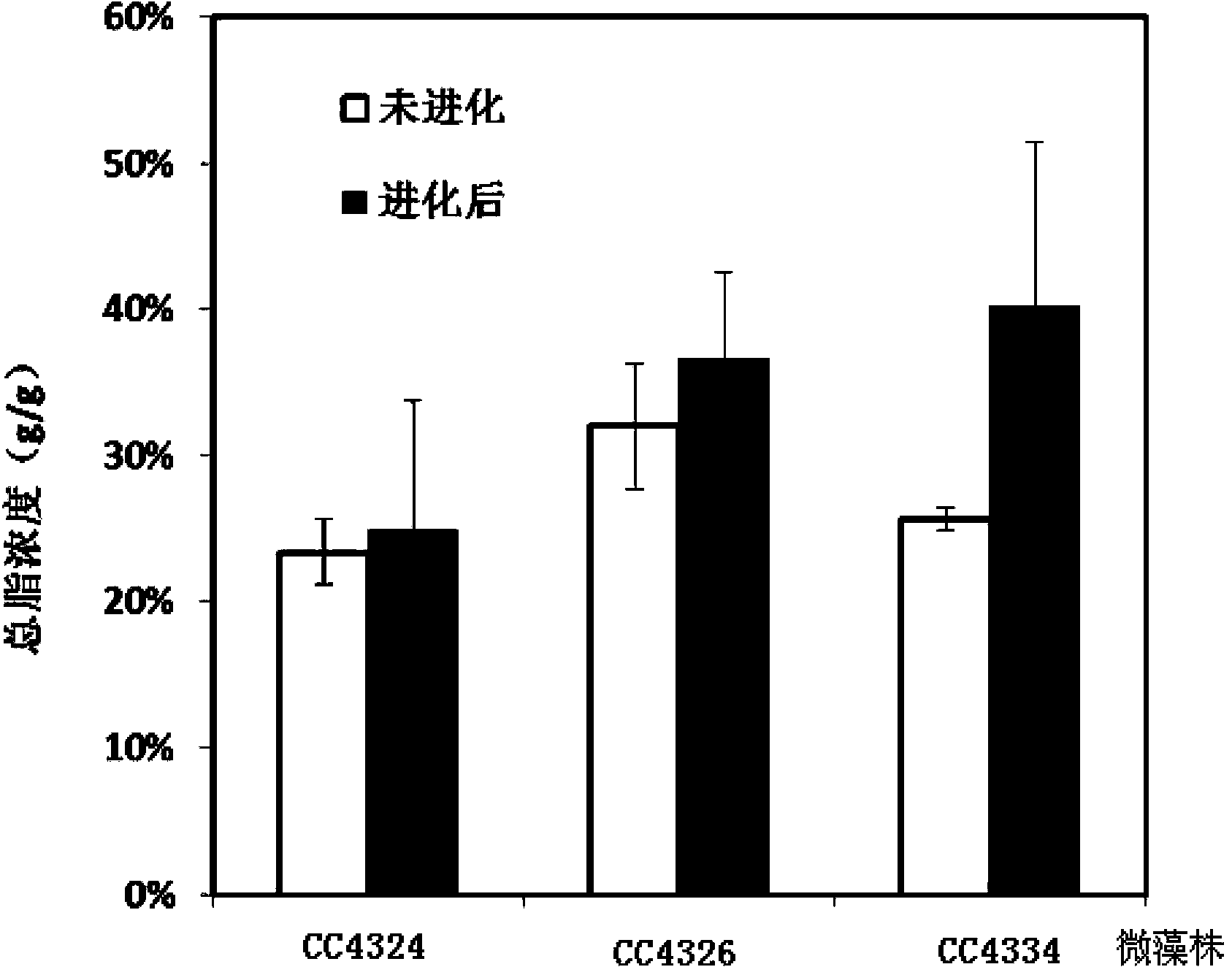

[0027] Microalgal strains used: Chlamydomonas reinhardtii wild strain CC4324 (Ball 330 arginine auxotrophy, no cell wall), mutant strain CC4326 (AGPase large subunit inactivation) and mutant strain CC4334 (isoamylase inactivation ) as an example to illustrate the feasibility of this technical solution. The above algae species are all from the Chlamydomonas Resource Center of the United States.

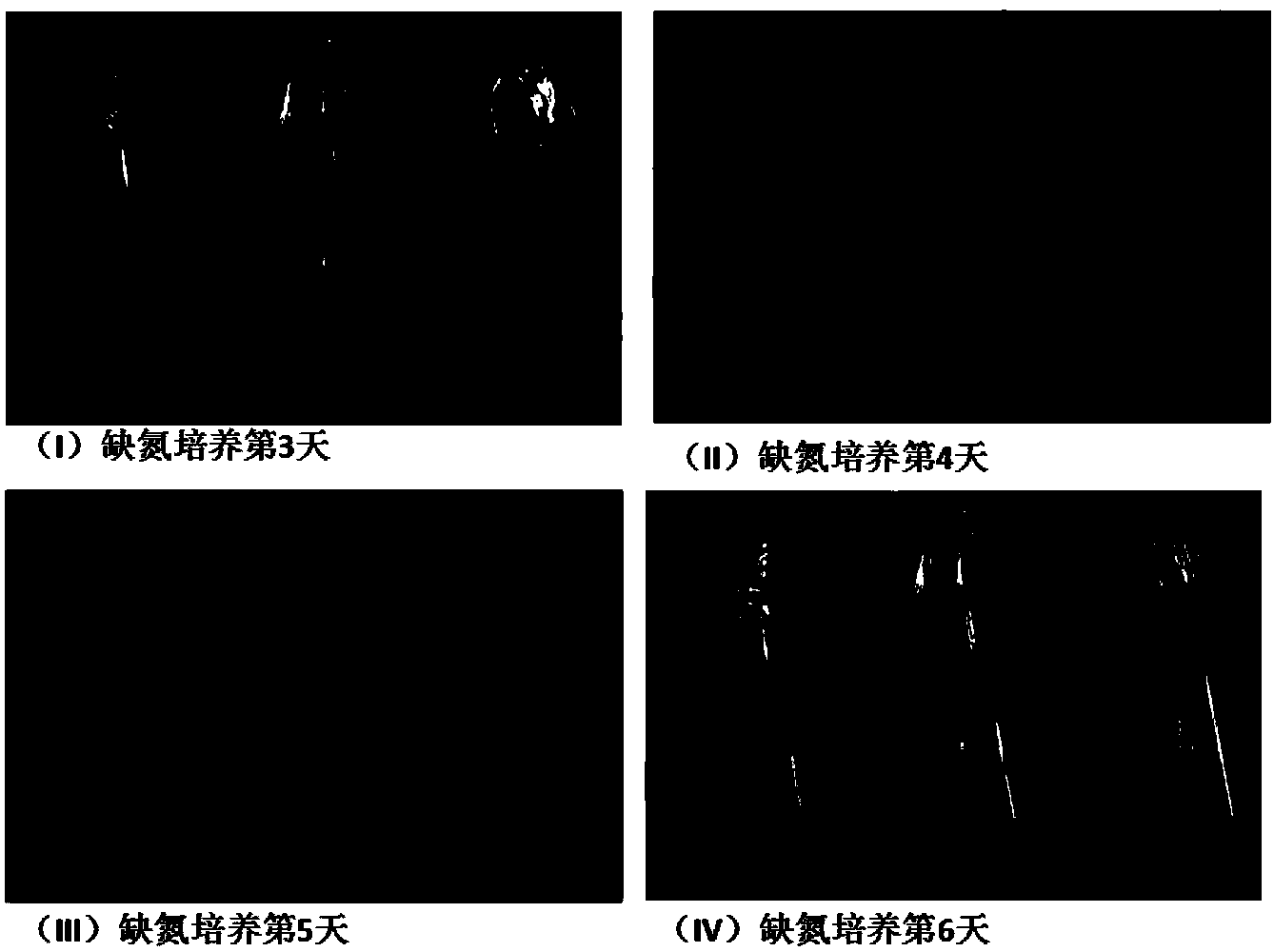

[0028] The steps for adaptive evolution of microalgal strains are as follows:

[0029] 1) The basal medium of the three microalgae strains is TAP liquid medium, at 25°C and 50μmol photons m -2 the s -1 cultured in a shaking incubator with continuous light. The first generation of microalgae strains (CC4324, CC4326 and CC4334) were measured by the optical density OD at 680nm 680 Under the condition of 0.1, each was inoculated in 50mL TAP medium (100mL Erlenmeyer shake flask), cultivated for 3 days, and measured the dry weight.

[0030] 2) Take the first-generation microalgae strain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com