A kind of personalized bone repair material and its preparation method

A bone repair and organic material technology, applied in the field of bioengineering, can solve problems such as difficult to repair bone tissue, shortage of donors, shortage of bone tissue, etc., and achieve the effect of reducing allogeneic rejection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1. Personalized bone tissue material ratio

[0051] Weigh 1g of hydroxyapatite or α-tricalcium phosphate or β-tricalcium phosphate or tetracalcium phosphate and place it in a container with one end closed, add 2ml of acetone and seal one end, shake to make the acetone infiltrate the hydroxyapatite.

[0052] Weigh 0.2g of PLGA (poly(D,L-lactic acid-co-glycolic acid), PLA:PGA=75:25) or PGA (polyglycolide) or PLA (poly(L- Lactic acid)), placed in a closed container at one end, after adding acetone with a volume of 0.2ml, the other end was closed to completely dissolve PLGA.

[0053] Completely add the dissolved organic material into the inorganic material, oscillate and stir evenly, and seal it.

[0054] Get a portion of lyophilized lipid microsphere powder, which contains 100ng / part of nerve cell growth factor (NGF), 120ng / part of recombinant human interferon (IFN-β), bone protein (BMP- 2) 100ng / part. Add it to the prepared material liquid above, and mix qui...

Embodiment 2

[0055] Example 2 Preparation of Personalized Bone Tissue Material

[0056] Use non-invasive computed tomography (CT) and magnetic resonance imaging (MRI) to collect individualized three-dimensional data of bone injuries. The collected tomographic image slices are processed by mimic or 3dMed software, converted into three-dimensional space vector data, and then passed through three-dimensional The design software Autodesk3ds Max is converted into a 3D printing model, and compiled into a 3D printer recognition file format such as an STL file.

[0057] Set the printing parameters of the three-dimensional material bracket. The materials between layers are vertically cross-stacked. Each layer is placed in parallel. The gap between each strip is 1mm, and the step height in the Z-axis direction is 0.1mm. X The moving speed in the axial and Y-axis directions is 2mm / s, the hole diameter of the outlet is controlled between 0.5mm-0.1mm, and the pressure of the outlet is controlled betwee...

Embodiment 3

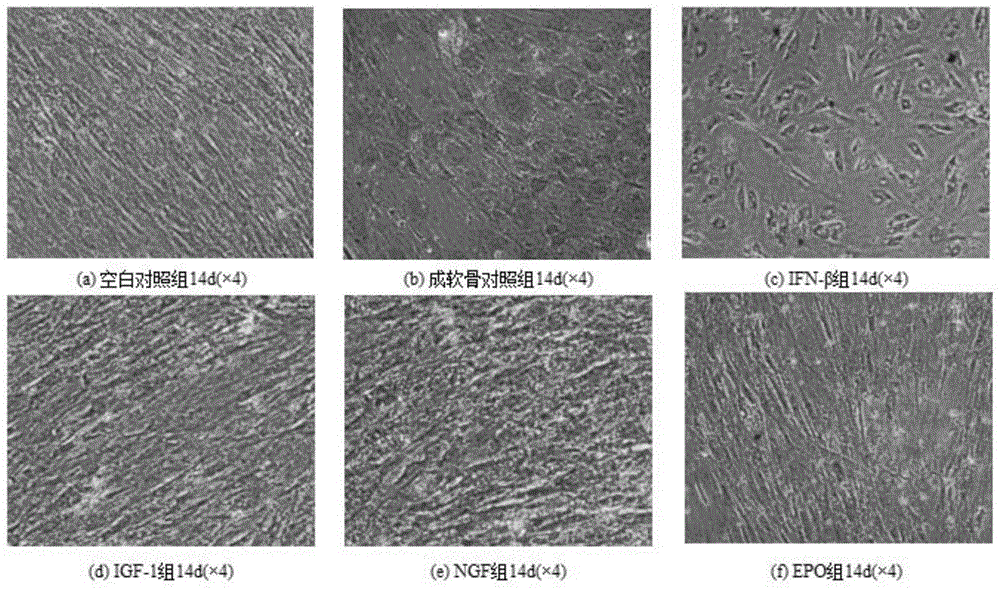

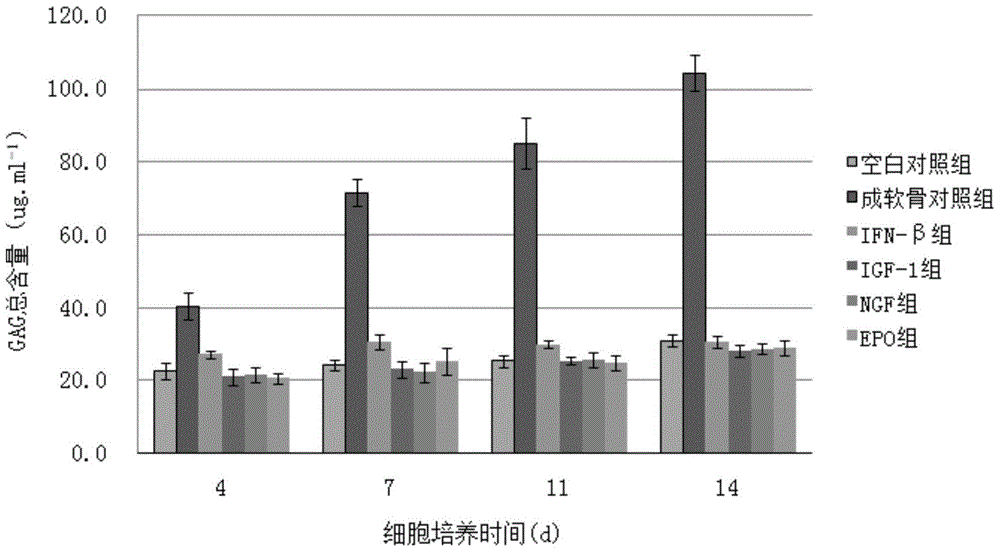

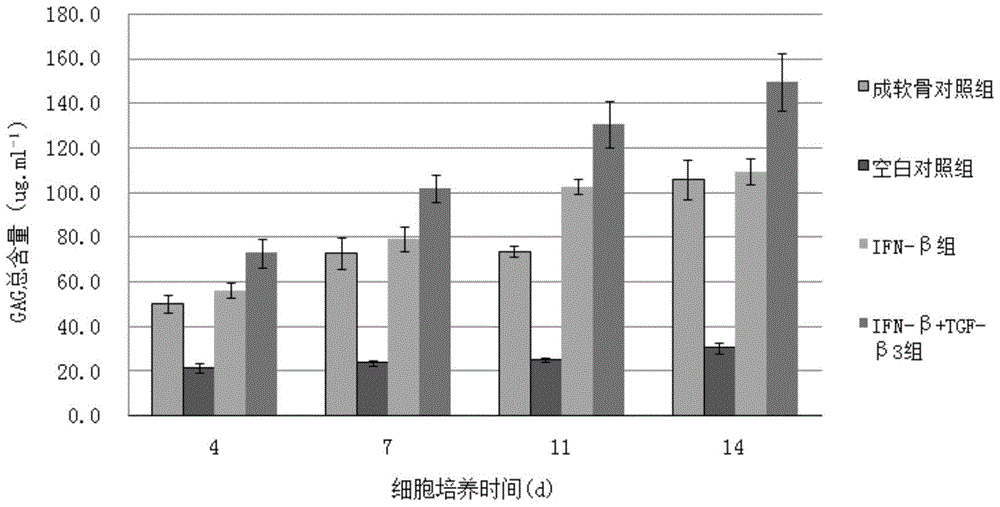

[0064] Example 3 Personalized bone tissue material (addition of cytokine IFN-β) induces chondrogenic differentiation of hMSC cells

[0065] Use non-invasive computed tomography (CT) and magnetic resonance imaging (MRI) to collect individualized three-dimensional data of bone injuries. The collected tomographic image slices are processed by mimic or 3dMed software, converted into three-dimensional space vector data, and then passed through three-dimensional The design software Autodesk3ds Max is converted into a 3D printing model, and compiled into a 3D printer recognition file format such as an STL file.

[0066] Set the printing parameters of the three-dimensional material bracket. The materials between layers are vertically cross-stacked. Each layer is placed in parallel. The gap between each strip is 1mm, and the step height in the Z-axis direction is 0.1mm. X The moving speed in the axial and Y-axis directions is 2mm / s, the hole diameter of the outlet is controlled between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com