Preparation method and application of high-molecular forward osmosis membrane

A forward osmosis membrane and polymer membrane technology, applied in the field of polymer forward osmosis membrane preparation, can solve the problems of small water flux, low salt retention rate, poor permeability, etc., and achieve high water flux and salt retention rate. High and hydrophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

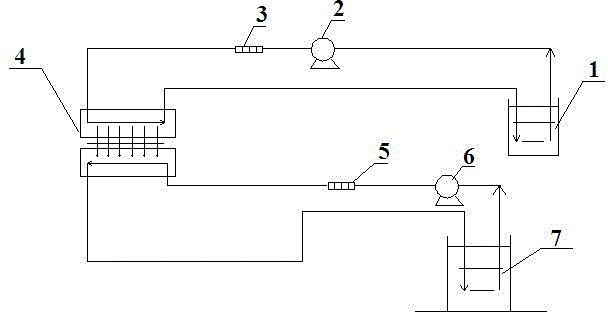

Image

Examples

Embodiment 1

[0030] (1) Mix 52g of 1,4-dioxane and 18g of acetone evenly to form a mixed solvent, then add 15g of cellulose acetate and stir until dissolved, then add 8g of methanol and 7g of lactic acid in sequence, and finally add 1g of carbon nanotubes, Stir mechanically at 30°C, and after fully dissolving, it becomes a transparent and clear solution, and the casting liquid is obtained;

[0031] (2) After ultrasonic defoaming of the casting solution for 2 hours, scrape the film in a vacuum drying oven at 30°C, and volatilize the solvent in a vacuum drying oven at 30°C for 60 seconds;

[0032] (3) Immerse the gel in deionized water to form a film, wash it with deionized water, and dry it in a vacuum oven for 24 hours to obtain a polymer forward osmosis membrane (finished membrane).

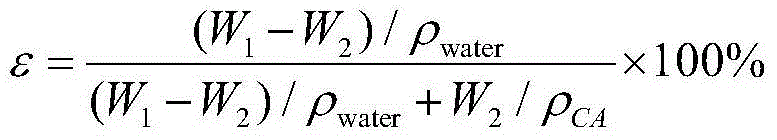

[0033] The contact angle of the polymer forward osmosis membrane was measured with a DSA100 contact angle meter from Kruss, Germany, to evaluate the surface hydrophilicity of the polymer forward osmosis memb...

Embodiment 2

[0038] (1) Add 20g of cellulose acetate to the mixed solvent mixed with 60g of N,N-dimethylformamide and 10g of acetone to dissolve completely, then add 8g of methanol and 7g of lactic acid in turn, and finally add 2g of nano silicon dioxide, Stir mechanically at 30°C, and after fully dissolving, it becomes a transparent and clear solution, and the casting solution is obtained;

[0039] (2) After ultrasonically degassing the casting solution for 2 hours, scrape the film in a vacuum drying oven at 30°C, and volatilize the solvent for 30s at 30°C;

[0040] (3) Immerse the gel in deionized water to form a film, wash it with deionized water, and dry it in a vacuum oven for 24 hours to obtain a polymer forward osmosis membrane (finished membrane).

[0041] The performance of the polymer forward osmosis membrane was tested according to the test method in Example 1, and the contact angle of the polymer forward osmosis membrane obtained finally was 56.5°, the porosity was 70.01%, and ...

Embodiment 3

[0043](1) Add 15g of cellulose acetate to a mixed solvent made of 52g of 1,4-dioxane and 18g of acetone, then add 5g of methanol and 10g of triethyl phosphate in turn, and finally add 2g of nanometer titanium dioxide. Mechanical stirring, fully dissolved into a transparent clear solution;

[0044] (2) After ultrasonic defoaming of the casting solution for 2 hours, scrape the film in a vacuum drying oven at 30°C, and volatilize the solvent at 30°C for 60s;

[0045] (3) Immerse the gel in deionized water to form a film, soak the residual solvent in deionized water at room temperature, wash the obtained polymer film with deionized water, and dry it in a vacuum drying oven for 24 hours to obtain the polymer film. Forward osmosis membrane (finished membrane).

[0046] According to the test method in Example 1, the performance of the polymer forward osmosis membrane is tested, and the final obtained polymer forward osmosis membrane has a contact angle of 63.6°, a porosity of 67.35%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Contact angle | aaaaa | aaaaa |

| Water flux | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com