Organic solvent miscible solution soaking bonding method on basis of micro-fluidic chip made of polymer material

A technology of microfluidic chips and organic solvents, which is applied in the fields of technology for producing decorative surface effects, microstructure technology, microstructure devices, etc., and can solve the problem of limited application and the realization of microfluidic chip integration and miniaturization Popularization and other issues, to achieve the effects of short bonding time, easy control of bonding conditions, and low process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0020] Specific implementation mode 1: In this implementation mode, the immersion bonding of a microfluidic chip based on an organic polymer material is carried out according to the following steps:

[0021] (1) Clean and dry the PMMA microfluidic chip to be bonded, and set aside.

[0022] (2) prepare dehydrated alcohol and chloroform miscible solution by volume ratio, the ratio range is at V 乙醇 :V 三氯甲烷 =20:1~10:1.

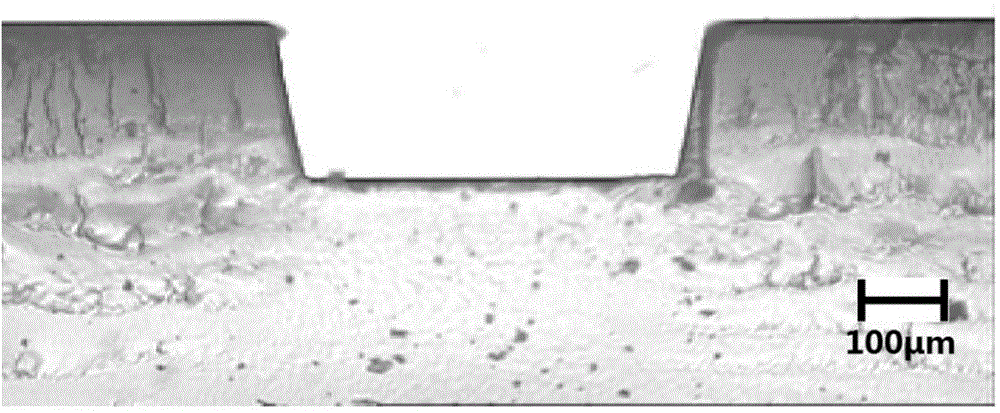

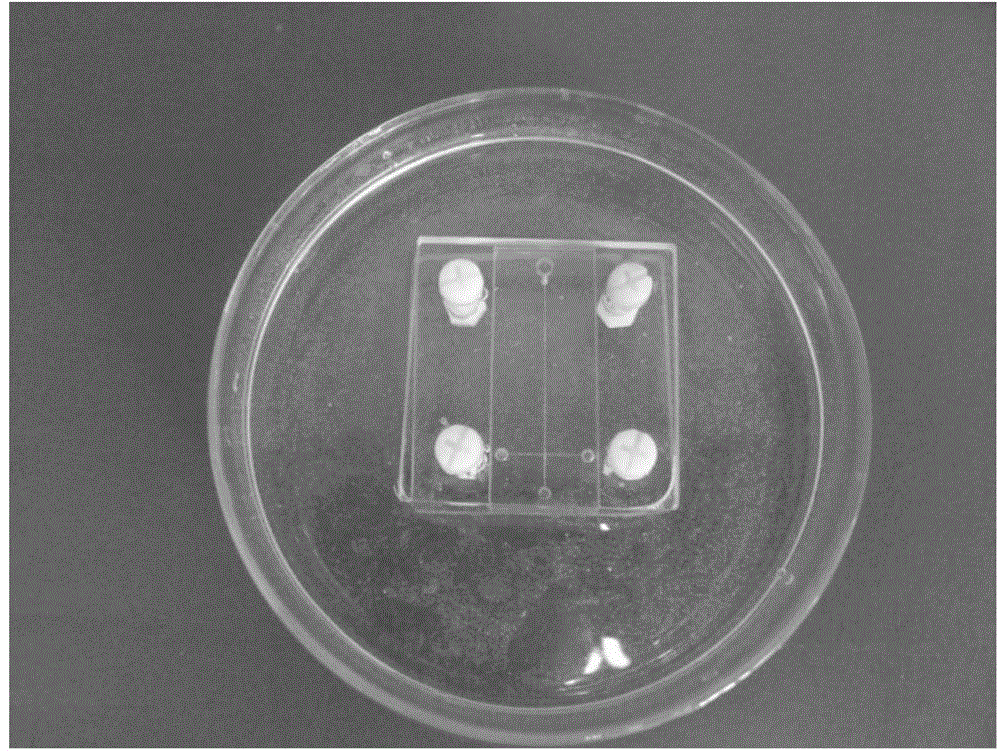

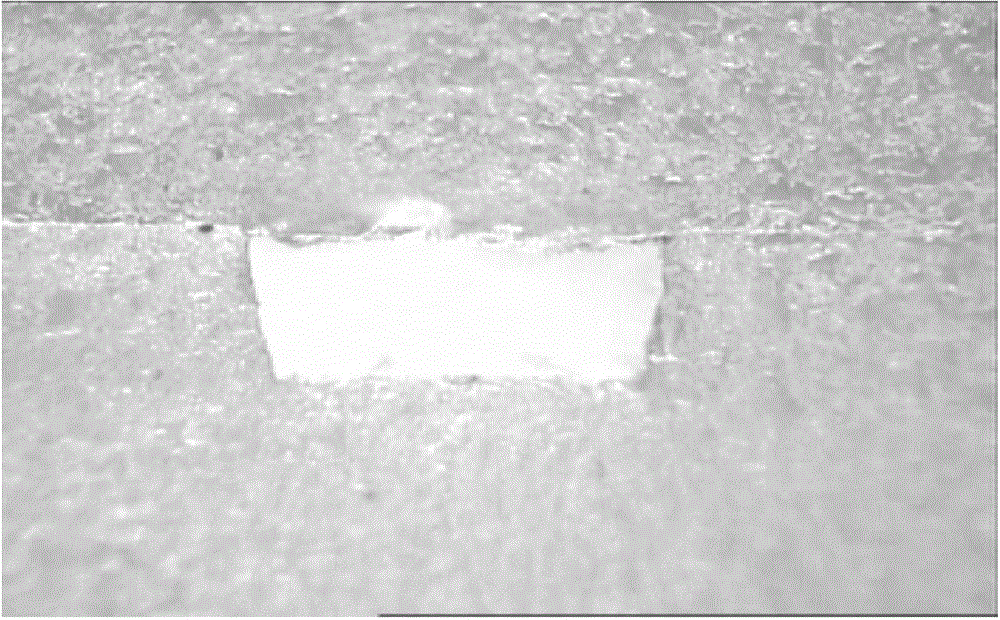

[0023] (3) Wet the above-mentioned PMMA substrate to be bonded in a miscible solution, and fix it with a quartz glass fixture, and ensure that there are no air bubbles between the bonding interfaces during the assembly process. Put the fixed chip into a Petri dish filled with a miscible solution. The photo of the cross-channel chip soaked in the miscible solution after assembly is shown in figure 1 shown. The photo of the cross-section of the 150 micron deep trapezoidal micro-channel before bonding is as follows figure 2 shown.

[0024] (4) Put the petri d...

specific Embodiment approach 2

[0027] Embodiment 2: This embodiment is different from Embodiment 1 in that the organic solvent used in the bonding process is acetone. Therefore, the bonding conditions are different from Embodiment 1. In view of the fact that acetone is less than chloroform to the dissolving power of PMMA material, in the preparation process of miscible solution, improved the content of acetone, the range of volume ratio is V 乙醇 :V 丙酮 =10:1~5:1. At the same time, the bonding time is also extended, and the bonding time ranges from 10 to 20 minutes.

specific Embodiment approach 3

[0028] Embodiment 3: This embodiment differs from Embodiment 1 in that the polymer chip material used in the bonding process is polymethylcarbonate (PC), so the bonding conditions are different from Embodiment 1. In view of the fact that the glass transition temperature of the PC material is about 60-80°C higher than that of the PMMA material, we increased the bonding temperature during the bonding process, and the temperature range was controlled at 40-60°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com