Embedded biological pre-oxidization aerated filter advanced-treatment method

A biological aerated filter and advanced treatment technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of short contact time between ozone and wastewater, short flow, difficult Realization and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

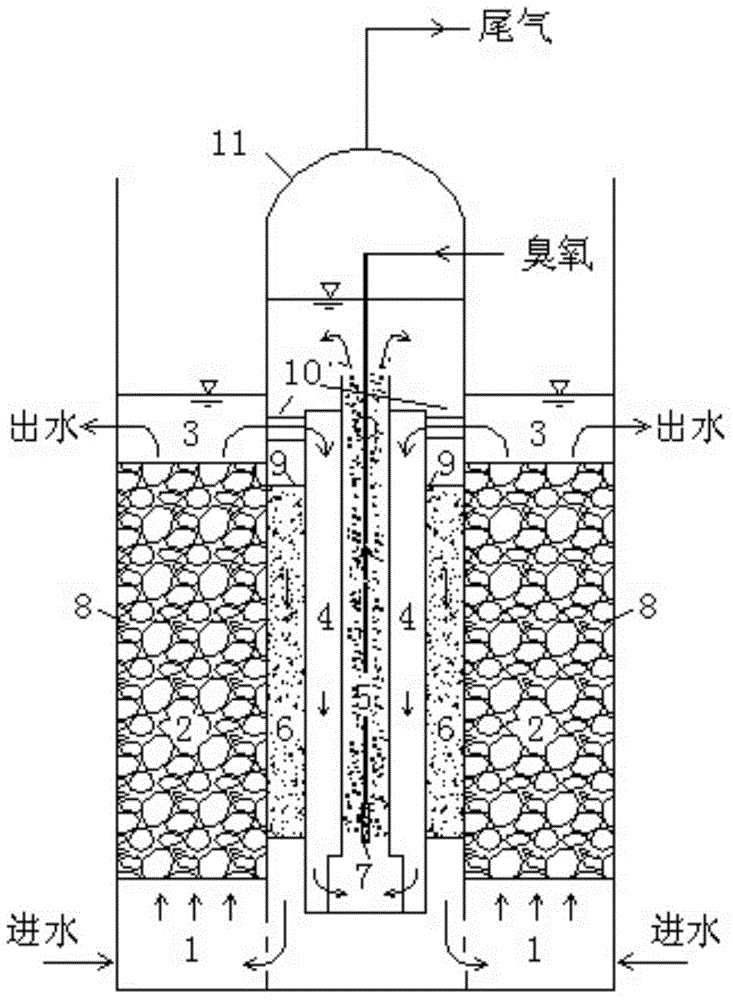

Embodiment 1

[0023] The circulating cooling water plant of a refining and chemical company in Heilongjiang has a daily sewage discharge volume of 720m 3 / d, the concentration ratio is controlled at about 5. The sewage water quality is poor, unable to meet the company's COD<60mg / L discharge requirements. The BOAF method of the present invention (shown in Figure-1 of the accompanying drawings) was used to carry out advanced treatment of the circulating water sewage of the circulating cooling water field, and a 10L / h field test was carried out. Under the lifting effect of ozonated air, the wastewater is circulated in the biochemical zone and the oxidation zone, with a reflux rate of 100L / h and a reflux ratio of 10. The hydraulic retention time of the wastewater in the biochemical zone is 6h, the hydraulic retention time of the reflux water in the diversion zone is 1min, the hydraulic retention time in the lifting zone is 10s, and the hydraulic retention time in the oxidation zone is 5min; th...

Embodiment 2

[0026] Acrylonitrile wastewater from a chemical plant in Liaoning, with a daily treatment capacity of 2000m 3 / d, currently using three-stage biochemical treatment technology for treatment. Due to the certain toxicity of acrylonitrile wastewater, the effluent quality of the existing treatment system is difficult to meet the local standard of Liaoning Province "Integrated Wastewater Discharge Standard" (DB21 / 1627-2008). The company intends to carry out advanced treatment of the existing biochemical effluent. The BOAF method of the present invention (shown in Figure-1 of the accompanying drawing) is used for advanced treatment of acrylonitrile biochemical effluent. Under the lifting effect of ozonated air, the wastewater is circulated in the biochemical zone and the oxidation zone, and the reflux ratio is 6. The hydraulic retention time of the wastewater in the biochemical zone is 6h, the hydraulic retention time of the return water in the diversion zone is 1.5min, the hydraul...

Embodiment 3

[0029] Refining wastewater from a refinery company in Guangdong, with a daily discharge of 7000m 3 / d, currently using oil separation-air flotation-two-stage A / O treatment technology, the COD and ammonia nitrogen in the effluent water are slightly high, which is difficult to meet the discharge requirements. Adopt BOAF method of the present invention (attachment figure 1 shown) to carry out small-scale research on biochemical effluent. Under the lifting effect of ozonated air, the wastewater circulates in the biochemical zone and the oxidation zone, the reflux ratio is 3 (the ratio of the reflux flow to the influent flow), the hydraulic retention time of the wastewater in the biochemical zone is 4h, and the reflux water is diverted The hydraulic retention time in the zone is 2min, the hydraulic retention time in the lifting zone is 30s, and the hydraulic retention time in the oxidation zone is 20min; the dosage of ozone in wastewater is 15mg / L.

[0030] The average COD of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com