Silicon nitride/silicon carbide complex phase porous ceramic and preparation method thereof

A technology of porous ceramics and nitriding rate, applied in the field of porous ceramics, can solve the problems of uneven void structure, poor net size forming, poor directional interconnection, etc., and achieve low shrinkage, high bending strength, and good corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Comparative Examples 1-3 and Examples 1-12

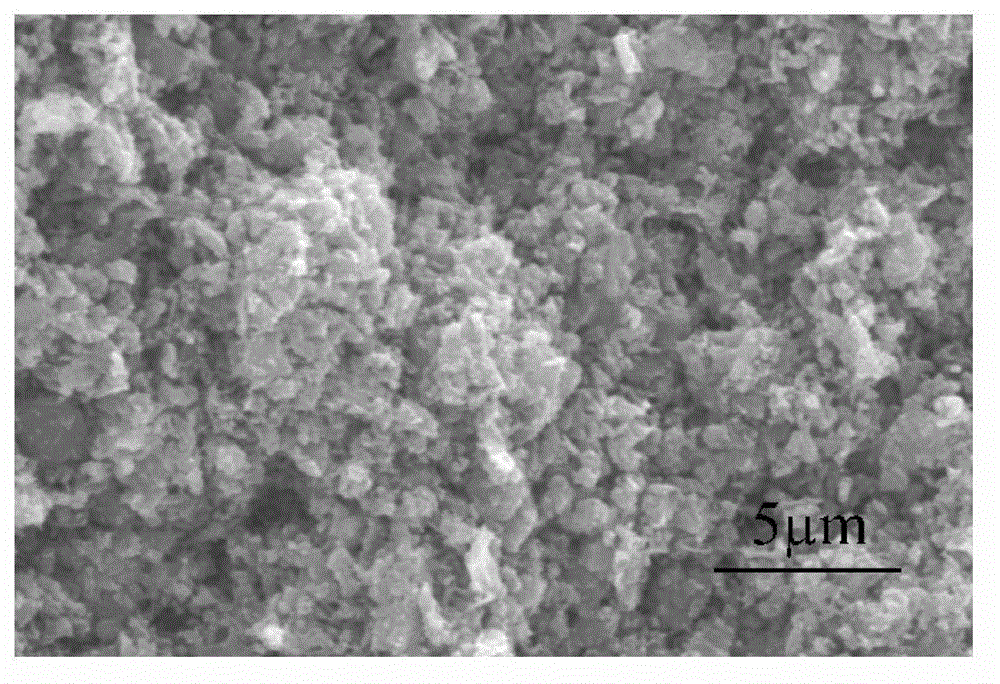

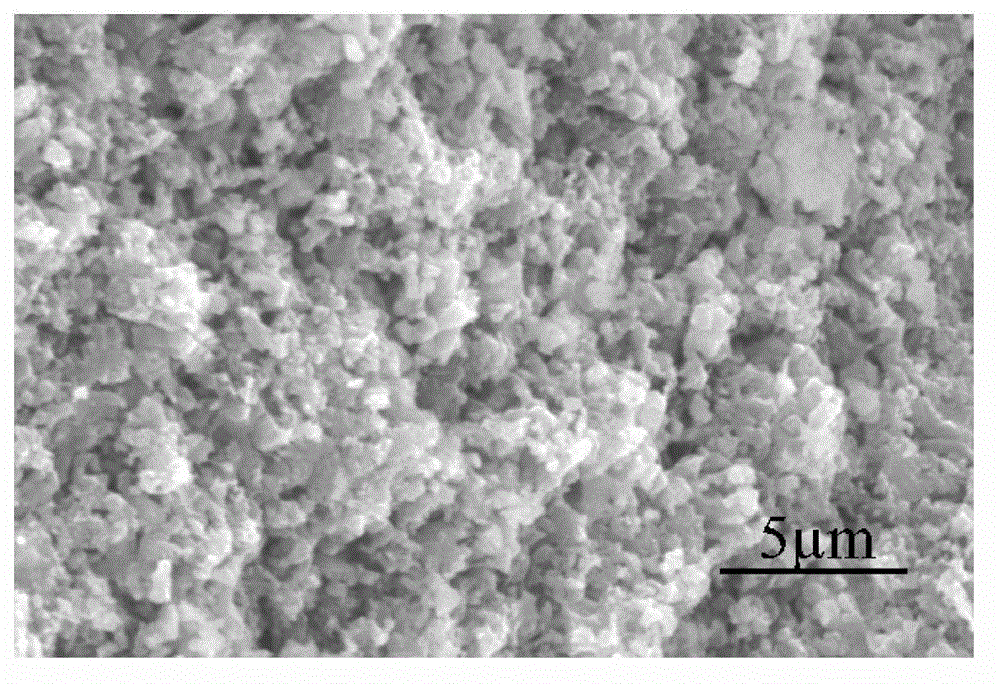

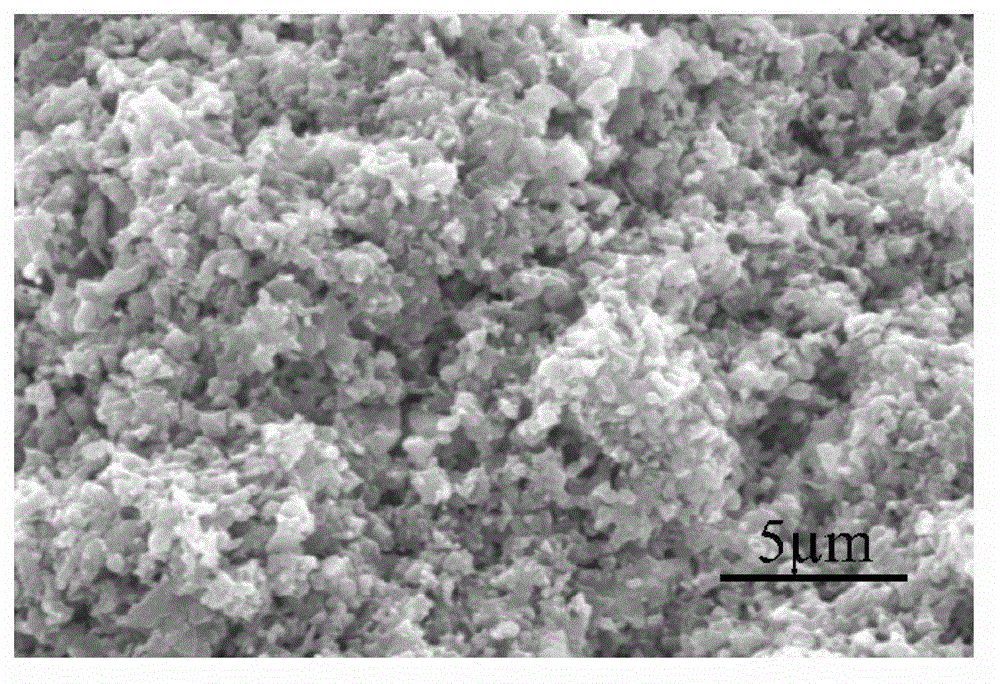

[0030] Weigh 70.588g of 1.3 micron Si powder and 29.412g of 0.5 micron SiC powder as raw materials, then weigh ZrO 2 with 8g Y 2 o 3 Sintering aid, using absolute ethanol as a dispersant, the total raw material powder (the sum of Si powder, SiC powder and sintering aid): the weight ratio of absolute ethanol: SiC ball is 1:1:2, after mixing After 24 hours of mechanical wet ball milling, it was mixed evenly to prepare a slurry. The obtained slurry was put into a constant temperature drying oven and dried at 60°C for 24 hours, then sieved through a 100-mesh sieve, and dry-pressed under a pressure of 10 MPa, and finally subjected to 200 MPa cold isostatic pressing to form a green body. Put the green body obtained by cold isostatic pressing into a vacuum hot-press sintering furnace for rapid nitriding reaction sintering, firstly raise the temperature to 1100°C at a rate of 15°C / min, and then slowly increase the temperature to T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com