Preparation method of plant nutrient solution

A plant nutrient solution and mixture technology, applied in the field of biotechnology and plant nutrition, can solve the problems of insufficient enzymatic hydrolysis, waste of resources, increased processing costs, etc., and achieve the effect of simple enzymatic hydrolysis process, low cost and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

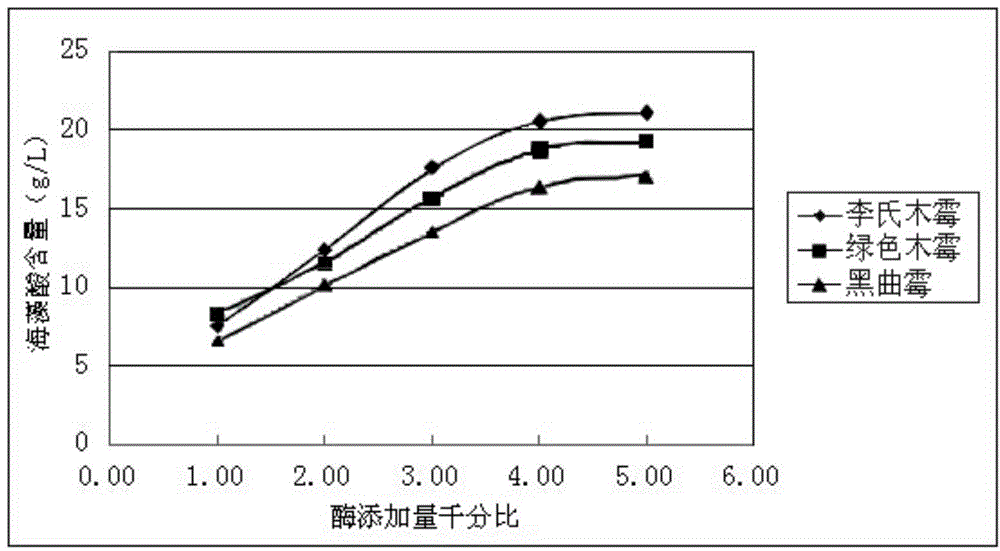

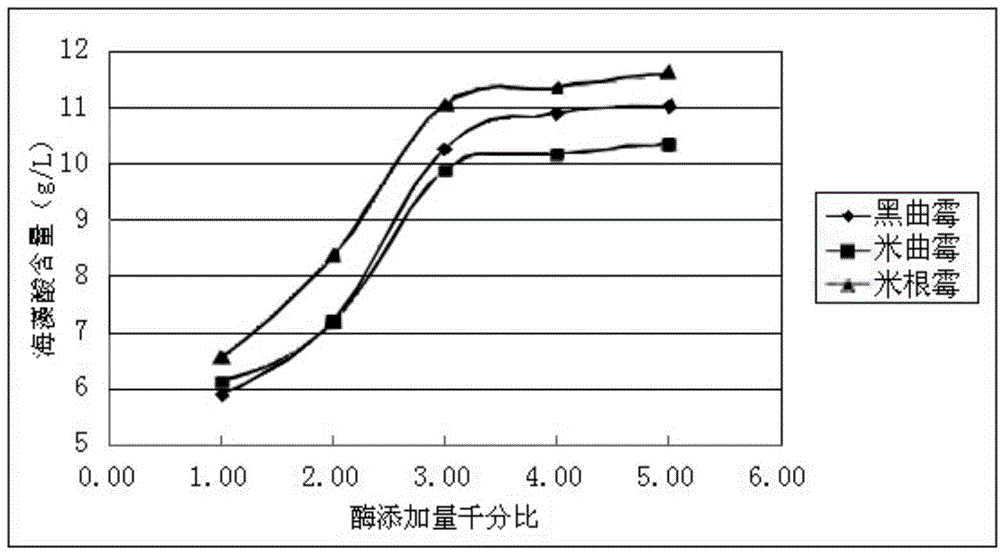

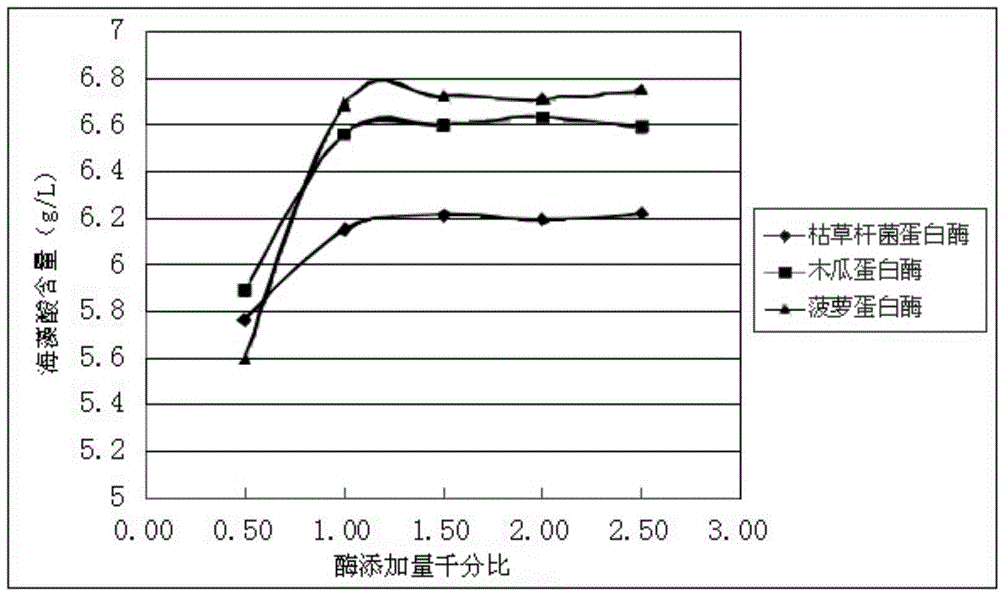

[0077] A compound microbial enzyme is composed of 100% cellulase, wherein the selected cellulase has an enzyme activity of 200,000 μ / g. Take 100ml of kelp slurry, add the compound microbial enzyme at a ratio of 0.4% to the kelp slurry to form a mixed solution, keep it warm for 18 hours, and measure the content of alginic acid in the supernatant to be 17.25g / L.

Embodiment 2

[0079] A compound microbial enzyme, which is formed by mixing 60% cellulase and 40% pectinase by mass percentage, wherein the selected cellulase has an enzyme activity of 120,000 μ / g, and the enzyme activity of pectinase The activity is 12,000 μ / g. Take 100ml of kelp slurry, add the compound microbial enzyme in a ratio of 0.4% to the kelp slurry to form a mixed solution, keep it warm for 18 hours, and measure the content of alginic acid in the supernatant to be 19.56g / L

Embodiment 3

[0081] A compound microbial enzyme, which is mixed with 60% cellulase, 35% pectinase and 5% protease by mass percentage, wherein the selected cellulase has an enzyme activity of 120,000 μ / g, The enzyme activity of pectinase is 10,500 μ / g, and that of protease is 25,000 μ / g. Take 100ml of kelp slurry, add the compound microbial enzyme at a ratio of 0.4% to the kelp slurry to form a mixed solution, keep it warm for 18 hours, and measure the content of alginic acid in the supernatant to be 21.32g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com