Preparation method of metal-organic framework compound with hierarchical pore structure

An organic framework, multi-level hole technology, applied in the direction of zinc organic compounds, copper organic compounds, etc., can solve problems such as the collapse of the overall structure, and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1. Preparation of hierarchically porous ZIF-8.

[0032] (1) Add 10ml (2mg / ml) polymer nanowire solution, 15ml methanol, and 25ml Zn(NO 3 ) 2 (250mM) methanol solution, 50ml 2-methylimidazole (250mM) methanol solution. Shake well and let stand at room temperature. After 24 hours, a white precipitate was obtained, which was collected by centrifugation, washed twice with methanol, and dried overnight in a vacuum oven to obtain 0.1238 g of a white solid.

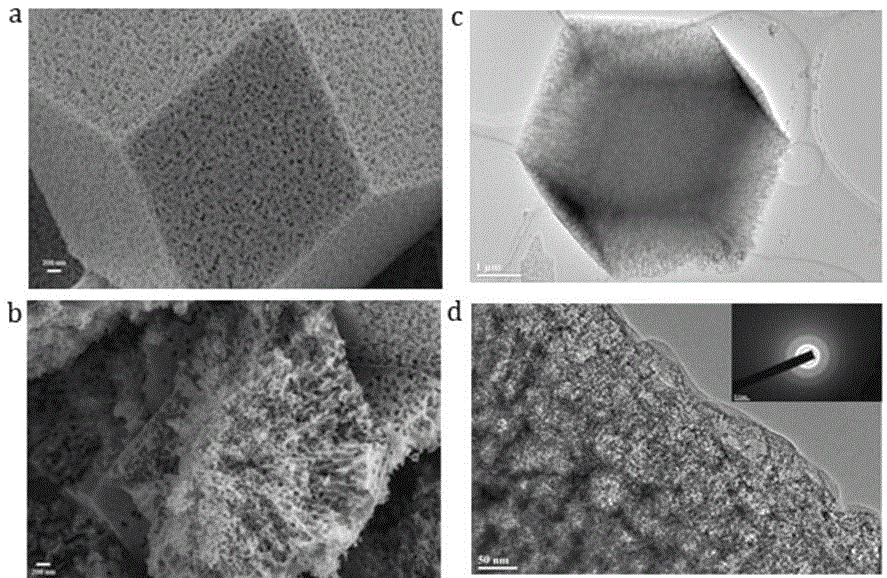

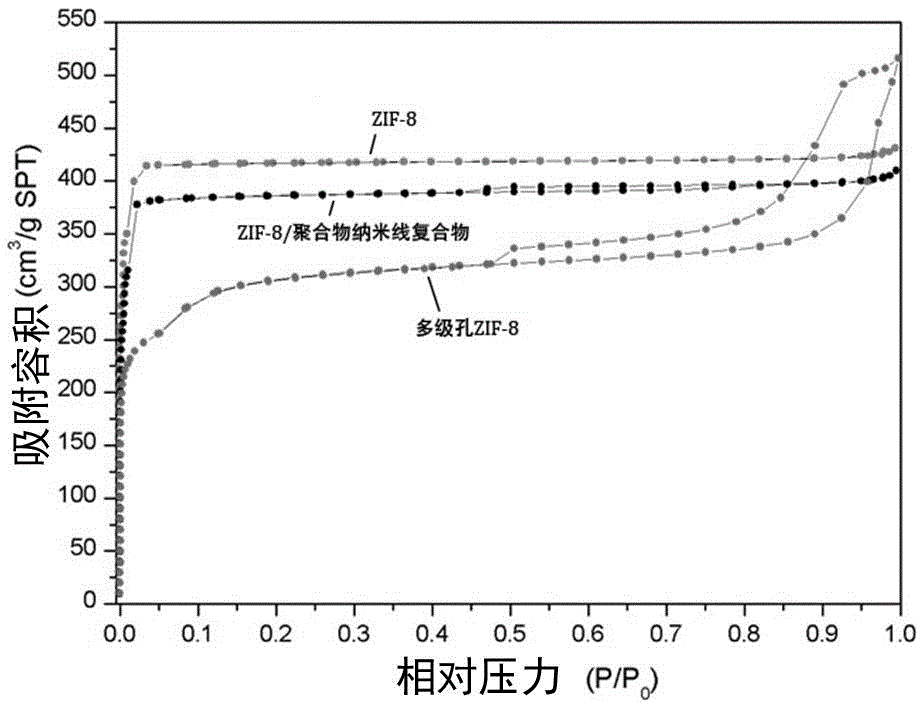

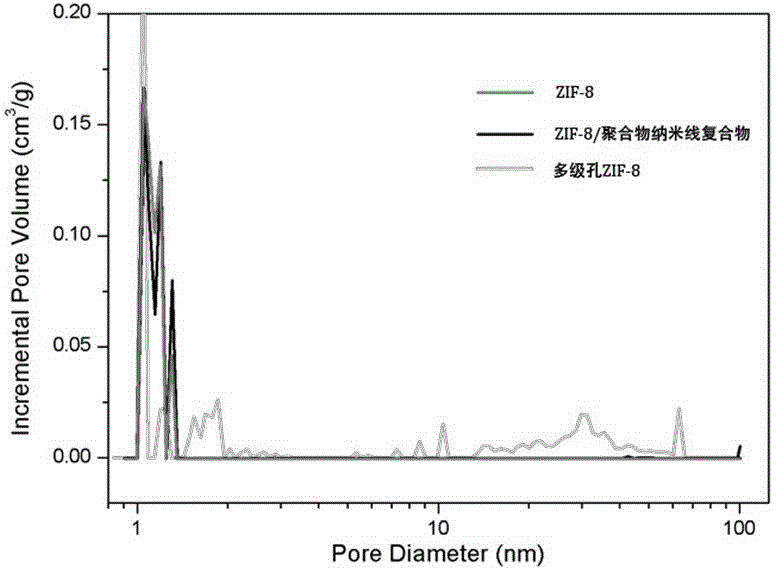

[0033] (2) The product was put into a muffle furnace and calcined at 350° C. for 4 hours to obtain 0.0915 g of a yellow solid. Field emission scanning electron microscopy, high resolution transmission electron microscopy, nitrogen adsorption and desorption experiment results are as follows: figure 1 , 2 , 3.

Embodiment 2

[0034] Example 2. Preparation of hierarchically porous ZIF-8.

[0035] (1) Add 2ml polymer nanowire (2mg / ml) solution, 83ml methanol, and 5ml Zn(NO 3 ) 2 · 6H 2 O (250mM) methanol solution, 10ml 2-methylimidazole (250mM) methanol solution. Shake well and let stand at room temperature. After 24 hours, a white flocculent precipitate was obtained, which was collected by centrifugation, washed twice with methanol, and dried overnight in a vacuum oven to obtain 0.0727 g of a white solid.

[0036] (2) The product was put into a muffle furnace, and calcined at 350° C. for 4 hours to obtain 0.0504 g of a yellow solid.

Embodiment 3

[0037] Example 3. Preparation of hierarchically porous ZIF-7.

[0038] (1) Add 10ml (2mg / ml) polymer nanowire solution, 15ml methanol, and 25ml Zn(NO 3 ) 2 · 6H 2 O (250mM) methanol solution, 50ml benzimidazole (250mM) methanol solution. Shake well and let stand at room temperature. After 3 days, a white precipitate was obtained, which was collected by centrifugation, washed twice with methanol, and dried overnight in a vacuum oven to obtain 0.3216 g of a white solid.

[0039] (2) The product was put into a muffle furnace and calcined at 400°C for 3 hours to obtain 0.2852 g of a white solid. The field emission scanning electron microscope of the product, the high resolution transmission electron microscope experiment results are as follows Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com