High-speed countercurrent chromatographic method for separating terpene component in tree moss extract

A high-speed countercurrent chromatography, tree moss extract technology, applied in material separation, analysis materials, measuring devices and other directions, can solve problems such as terpene components that have not yet been seen, achieve easy popularization and use, reduce changes in properties, and process Simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

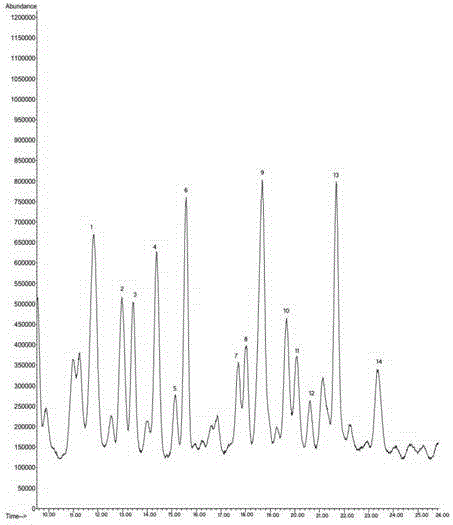

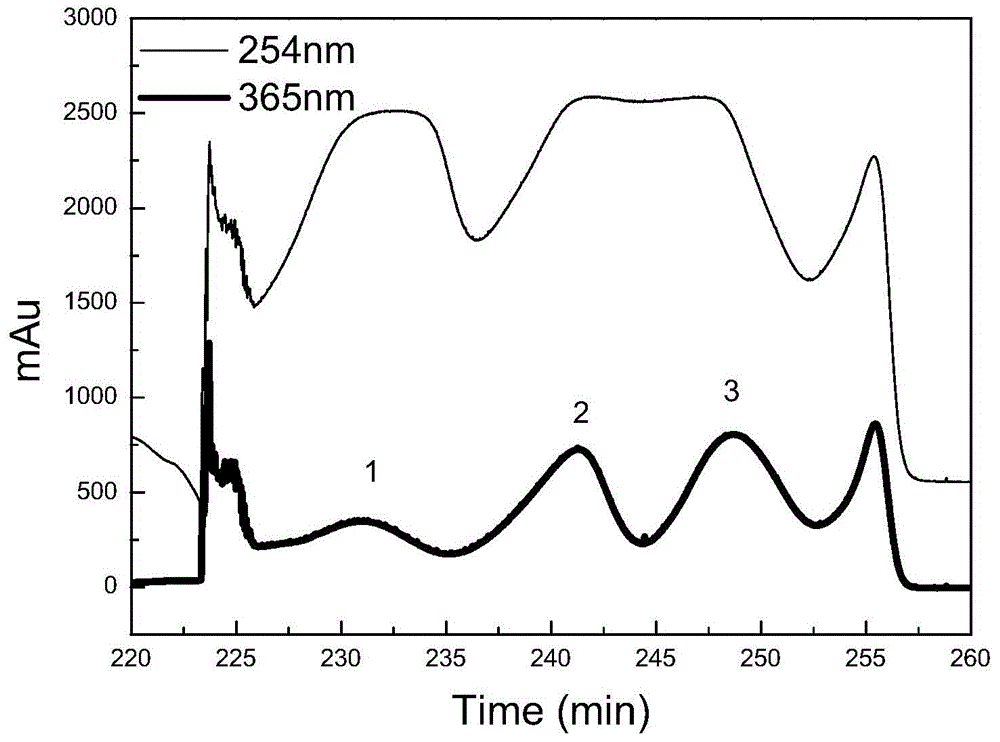

Image

Examples

Embodiment 1

[0033] Mix n-hexane, ethyl acetate, ethanol, and water according to the volume ratio of 0.9:0.9:1:1, shake vigorously for 15 minutes, and after standing for 2 hours, the mixed solution is divided into two layers. The upper layer after layering is used as the stationary phase, and the lower layer is used as the Mobile phase: Weigh 1g of the tree moss extract sample, add 20ml of mobile phase, stir and ultrasonically disperse for 10min to obtain the sample solution to be separated.

[0034] A TBE-300 semi-preparative high-speed countercurrent chromatograph (Shanghai Tongtian Biochemical Technology Co., Ltd.) was used. The instrument was equipped with a pump, a 10-30ml sampling valve, an ultraviolet detector and a recorder. Its multilayer winding polytetrafluoroethylene tube The column capacity is about 300ml. First fill the separation column of high-speed countercurrent chromatography with stationary phase at a flow rate of 10mL / min, then turn on the speed controller to make the ...

Embodiment 2

[0038] Mix n-hexane, ethyl acetate, ethanol, and water according to the volume ratio of 0.7:0.7:0.8:1.1, shake vigorously for 20 minutes, and divide the solution into two layers after standing for 3 hours. The upper layer after layering is used as the stationary phase, and the lower layer is used as the Mobile phase: Weigh 1g of the tree moss extract sample, add 30ml of mobile phase, stir and ultrasonically disperse for 5min to obtain the sample solution to be separated.

[0039] A TBE-300 semi-preparative high-speed countercurrent chromatograph (Shanghai Tongtian Biochemical Technology Co., Ltd.) was used. The instrument was equipped with a pump, a 10-30ml sampling valve, an ultraviolet detector and a recorder. Its multilayer winding polytetrafluoroethylene tube The column capacity is about 300ml. First fill the separation column of high-speed countercurrent chromatography with a stationary phase at a flow rate of 30mL / min, then turn on the speed controller to make the high-s...

Embodiment 3

[0041] Mix n-hexane, ethyl acetate, ethanol, and water according to the volume ratio of 1.1:1.1:0.8:1.1, shake vigorously for 20 minutes, and divide the solution into two layers after standing for 2.5 hours. The upper layer after layering is used as the stationary phase, and the lower layer is As the mobile phase: Weigh 1g of the tree moss extract sample, add 25ml of the mobile phase, stir and disperse by ultrasonication for 8min to obtain the sample solution to be separated.

[0042] A TBE-300 semi-preparative high-speed countercurrent chromatograph (Shanghai Tongtian Biochemical Technology Co., Ltd.) was used. The instrument was equipped with a pump, a 10-30ml sampling valve, an ultraviolet detector and a recorder. Its multilayer winding polytetrafluoroethylene tube The column capacity is about 300ml. First fill the separation column of high-speed countercurrent chromatography with a stationary phase at a flow rate of 20mL / min, then turn on the speed controller to make the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com