Large-section nodular cast iron melt mass stokehole control method

A technology of nodular cast iron and control method, which is applied in the fields of instrument, calculation, electrical digital data processing, etc., can solve the problems of poor production repeatability, graphite distortion, and graphite shape change.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

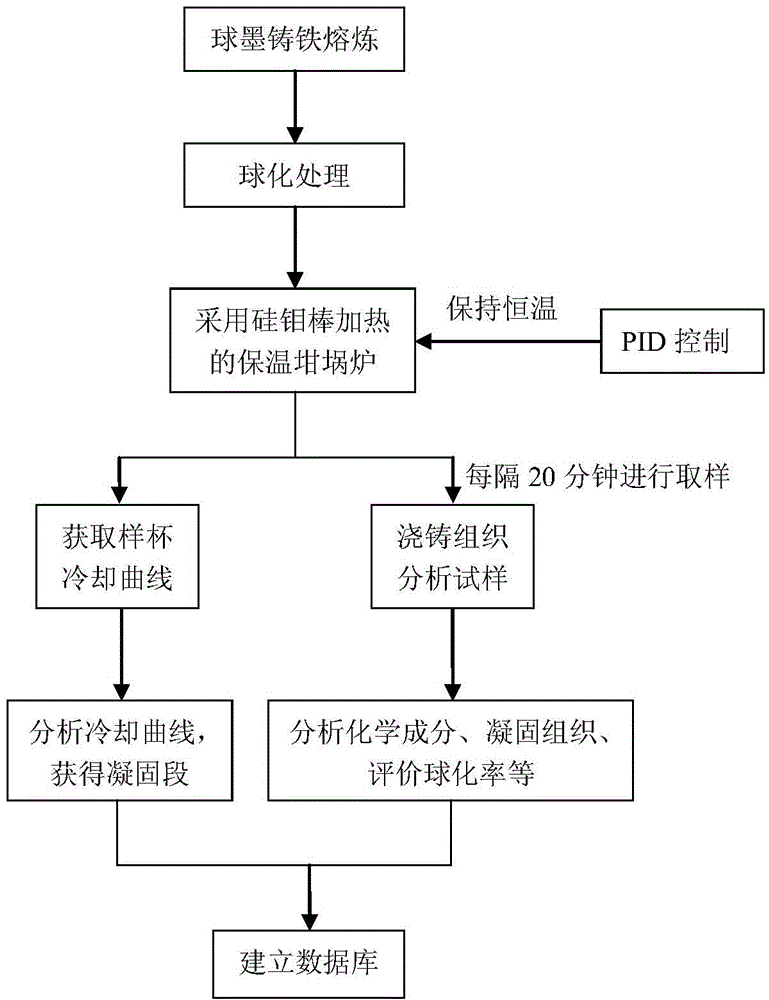

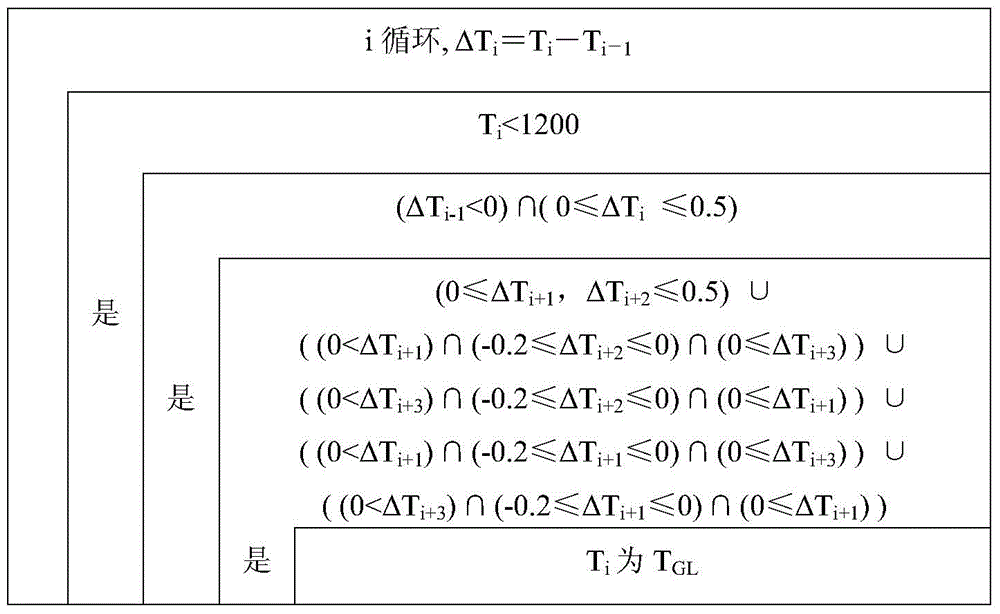

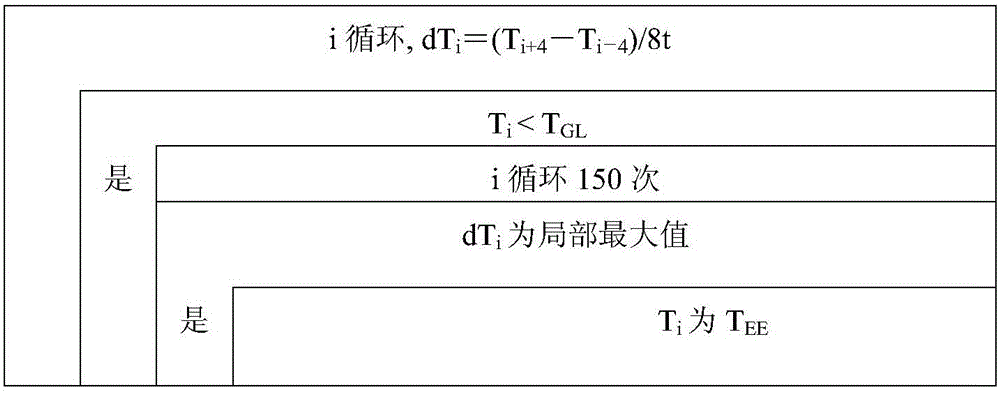

Method used

Image

Examples

Embodiment 1

[0064] The cupola furnace is used to smelt the molten ductile iron, and the grade of the cast iron is QT450-10. The ingredients are cast pig iron, scrap steel, recycled materials, ferrosilicon, and ferromanganese alloy; the nodularization treatment temperature is 1460-1500°C, the nodulizer is rare earth magnesium ferrosilicon, the inoculant is 75SiFe alloy, and the nodularization and inoculation are both adopted wire feeding method . The cooling curve of the ductile iron was collected separately by using the thermal analysis sample cup, and the microstructure analysis sample was cast at the same time. Using the method for controlling the quality of large-section ductile iron melt in front of the furnace of the present invention, the collected thermal analysis curves are evaluated, and the chemical composition of the molten iron after treatment is analyzed using a German Spectro Analytical Instruments GMBH LAVMB08A direct-reading spectrometer. Microscopically analyze the metal...

Embodiment 2

[0074] The cupola furnace is used to smelt the molten ductile iron, and the grade of the cast iron is QT450-10. The ingredients are cast pig iron, scrap steel, furnace charge, ferrosilicon, and ferromanganese alloy; the nodularization treatment temperature is 1460-1500°C, the nodulizer is rare earth magnesium ferrosilicon, the inoculant is SiBa alloy, and both nodularization and inoculation adopt wire feeding method . The cooling curve of the ductile iron was collected separately by using the thermal analysis sample cup, and the microstructure analysis sample was cast at the same time. Insulate the nodular cast iron molten iron after spheroidization in the insulated crucible furnace, and cast the sample for microstructure analysis after 6 hours of insulated heat. Using the method for controlling the quality of large-section ductile iron melt in front of the furnace of the present invention, the collected thermal analysis curves are evaluated, and the chemical composition of t...

Embodiment 3

[0083] The cupola furnace is used to smelt the molten ductile iron, and the grade of the cast iron is QT450-10. The ingredients are cast pig iron, scrap steel, furnace charge, ferrosilicon, and ferromanganese alloy; the nodularization treatment temperature is 1460-1500°C, the nodulizer is rare earth magnesium ferrosilicon, the inoculant is SiBa alloy, and both nodularization and inoculation adopt wire feeding method . The cooling curve of the ductile iron was collected separately by using the thermal analysis sample cup, and the microstructure analysis sample was cast at the same time. Insulate the nodular cast iron molten iron after spheroidization in the insulated crucible furnace, and cast the sample for microstructure analysis after 6 hours of insulated heat. Using the method for controlling the quality of large-section ductile iron melt in front of the furnace of the present invention, the collected thermal analysis curves are evaluated, and the chemical composition of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com