Preparation method of porous carbon-tin nanocomposite material for lithium battery cathode

A nanocomposite material and composite material technology are applied in the field of preparation of porous carbon-tin nanocomposite materials for lithium battery negative electrodes, which can solve the problems of poor conductivity, consumption of lithium ions, restricting high capacity, etc., and achieve the effect of short preparation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

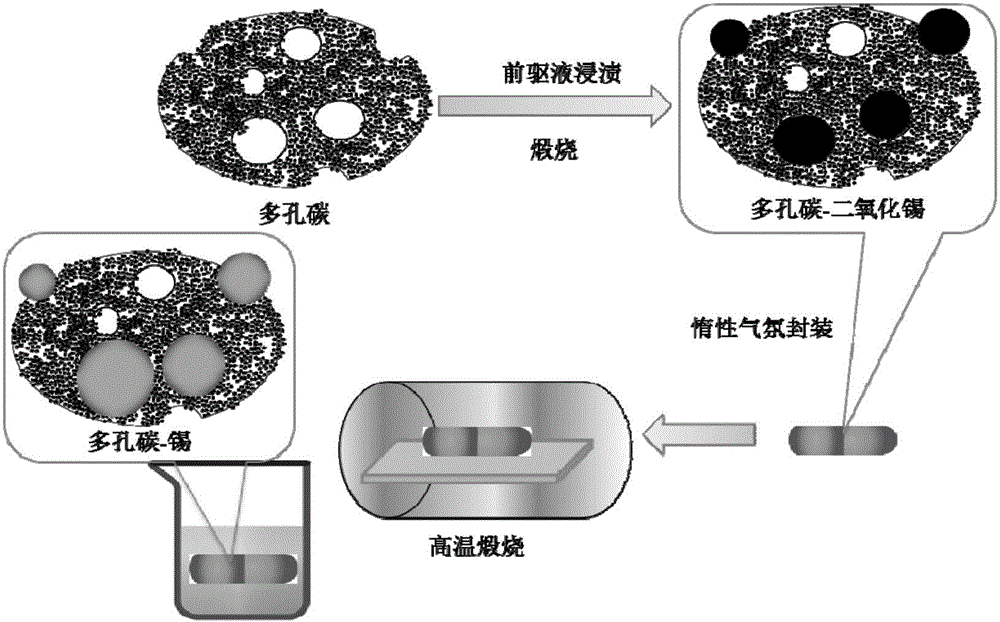

[0027] A method for preparing a porous carbon-tin nanocomposite material for a negative electrode of a lithium battery, the principle of which is as follows figure 1 As shown, the following steps are taken:

[0028] The first step: the present invention prepares a porous carbon matrix by carbonizing waste crops at 500°C.

[0029] The second step: the porous carbon matrix is dispersed in a 0.1 mol / L tin precursor solution to obtain a porous carbon-tin dioxide composite material.

[0030] The third step: heating and reacting the porous carbon-tin dioxide composite material with the sucrose solution to obtain the precursor of the carbon-coated nanocomposite material.

[0031] Step 4: Seal the precursor prepared in the previous step in a metal can under a nitrogen atmosphere, and at the same time heat the tube furnace to 900°C, and keep the furnace mouth of the tube furnace open. Use long-handled metal tongs to hold the metal can containing the precursor, and let it react brie...

Embodiment 2

[0034] A method for preparing a porous carbon-tin nanocomposite material for a lithium battery negative electrode, comprising the following steps:

[0035] The first step: the present invention prepares a porous carbon matrix by carbonizing waste crops at 700°C.

[0036] The second step: the porous carbon matrix is dispersed in a 0.5 mol / L tin precursor solution to obtain a porous carbon-tin dioxide composite material.

[0037] The third step: heating and reacting the porous carbon-tin dioxide composite material with the sucrose solution to obtain the precursor of the carbon-coated nanocomposite material.

[0038] Step 4: Seal the precursor prepared in the previous step in a metal can under a nitrogen atmosphere, and at the same time heat the tube furnace to 950°C, and keep the furnace mouth of the tube furnace open. Use long-handled metal pliers to hold the metal can containing the precursor, and let it react briefly in a high-temperature tube furnace for 10 minutes, then ...

Embodiment 3

[0041] A method for preparing a porous carbon-tin nanocomposite material for a lithium battery negative electrode, comprising the following steps:

[0042] The first step: the present invention prepares a porous carbon matrix by carbonizing waste crops at 600°C.

[0043] The second step: the porous carbon matrix is dispersed in a 1mol / L tin precursor solution to obtain a porous carbon-tin dioxide composite material.

[0044] The third step: heating and reacting the porous carbon-tin dioxide composite material with the glucose solution to obtain the precursor of the carbon-coated nanocomposite material.

[0045]Step 4: Seal the precursor prepared in the previous step in a metal can under a nitrogen atmosphere, and at the same time heat the tube furnace to 1000°C, and keep the furnace mouth of the tube furnace open. Use long-handled metal pliers to hold the metal can containing the precursor, and let it react briefly in a high-temperature tube furnace for 30 minutes, then qui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com