Sectionalized quenching fixed bed reactor and application method thereof

A bed reactor and reactor technology, applied in the field of preparation of ethylene glycol, segmented quenching fixed bed reactor, can solve the problems of difficult enlargement of the reactor, time-consuming and laborious, inconvenient operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] The synthesis of embodiment 1 dimethyl oxalate

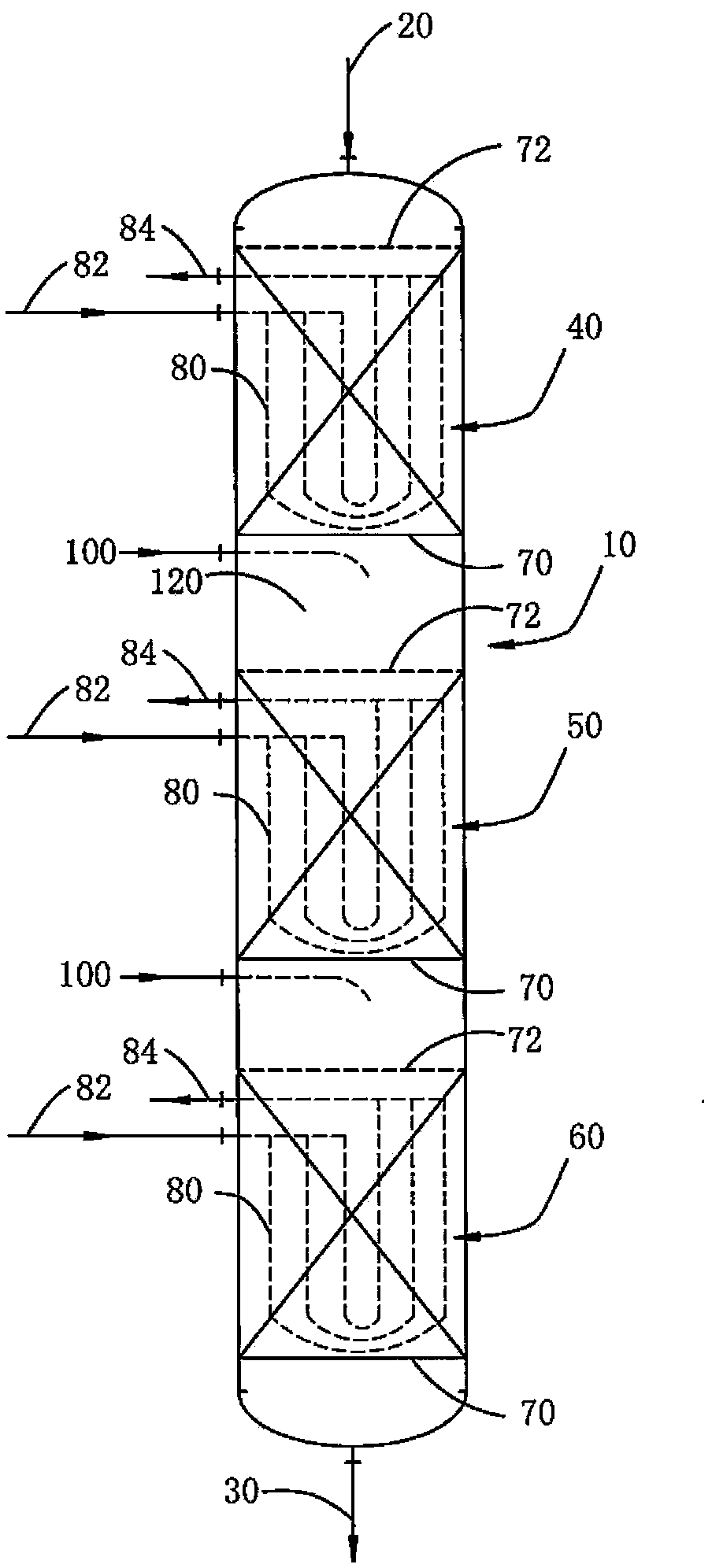

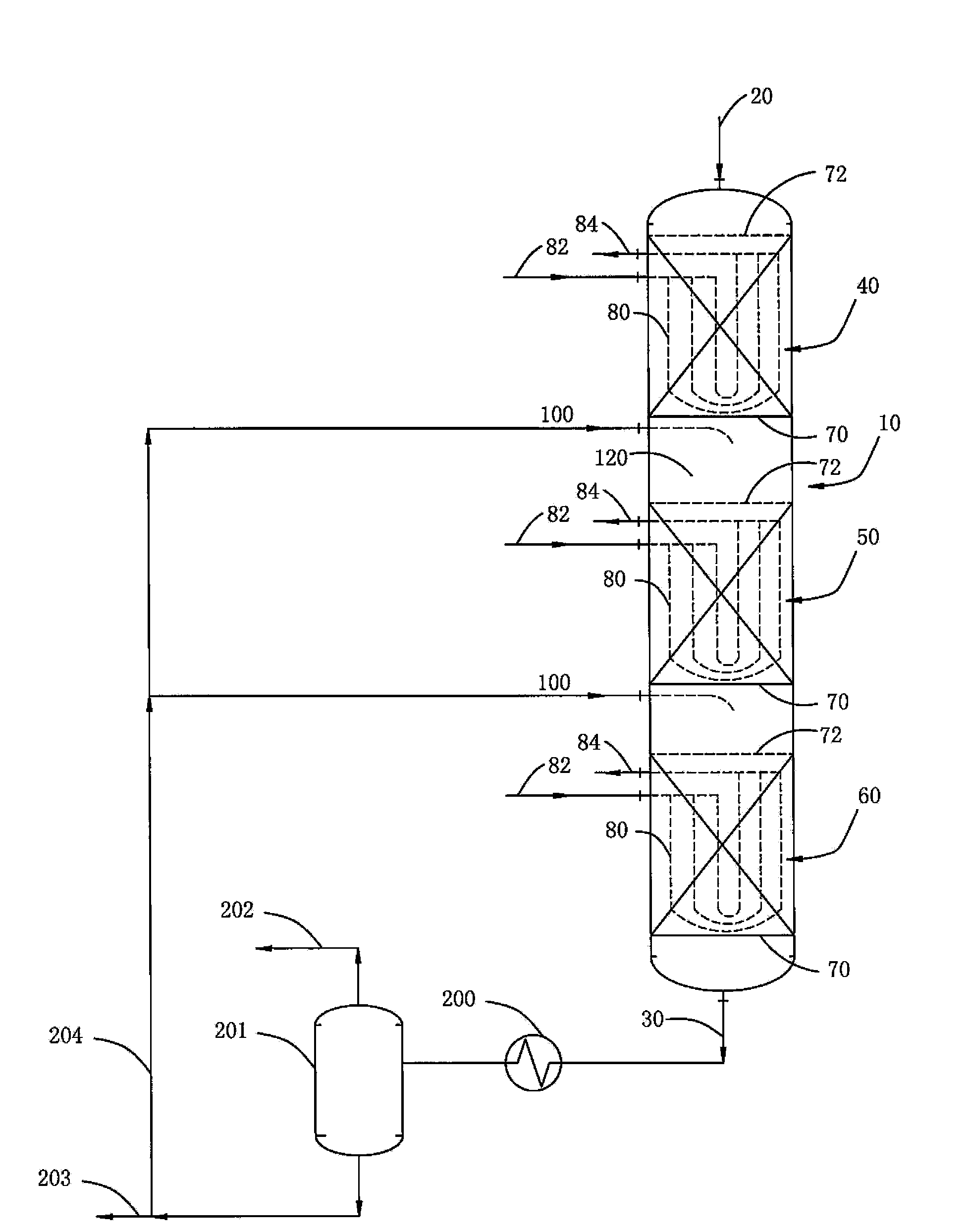

[0078] In this example using figure 1 The reactor shown has a diameter of 0.1m and a height of 2.5m, in which there are three stages of catalyst beds, and in order from top to bottom, the heights of each stage of the bed are 0.5m, 0.5m, and 1m respectively. 9.38 kg of alumina-supported palladium catalyst, the content of palladium in the catalyst is 1%, and the particle size is 5mm. The interval between catalyst beds of each stage (that is, the height of the premixing space) is 300mm. Mix CO feed gas and nitrite at a volume ratio of 2:1 for 3000hr -1 The space velocity is introduced from the reactant inlet at the top of the reactor, and passes through the three-stage catalyst bed in sequence. The pressure inside the reactor was 0.4 MPag. Two quenching agent inlets are arranged between the three-stage catalyst beds, and dimethyl oxalate at normal temperature is sprayed into the reactor with a flow rate of 0.04l / min resp...

Embodiment 2

[0079] The separation of embodiment 2 dimethyl oxalate

[0080] In this example, the gas stream obtained in Example 1 was introduced into a condensation separation column, and liquid dimethyl oxalate was separated under the conditions of a temperature of 75° C. and a pressure of 0.4 Mpag.

Embodiment 3

[0081] The hydrogenation reaction of embodiment 3 dimethyl oxalate

[0082] In this example, using figure 1 The reactor shown has a diameter of 0.1m and a height of 2.5m, in which there are three stages of catalyst beds, and in order from top to bottom, the heights of each stage of the bed are 0.5m, 0.5m, and 1m respectively. 5.966 kilograms of alumina-supported cuprous oxide catalyst, the particle size of the catalyst is 5mm. The interval between catalyst beds of each stage (that is, the height of the premixing space) is 300mm. The dimethyl oxalate obtained in Example 2 was dissolved in methanol solution to obtain a methanol solution with a concentration of 50% by weight. The methanol solution was injected into the gasifier using a high pressure metering pump, and the resulting gaseous species was fed into the reactor from the reactant inlet at the top of the reactor. The liquid hourly space velocity of wherein said dimethyl oxalate is 0.5g / ml·h. At the same time, the hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com