Construction and application of high-temperature high-yield engineering strain for producing ethanol

A technology of engineering strains and ethanol, applied in the direction of fungi, microorganism-based methods, microorganisms, etc., can solve the problems of fermentation rate, yield and insufficient ability to utilize xylose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

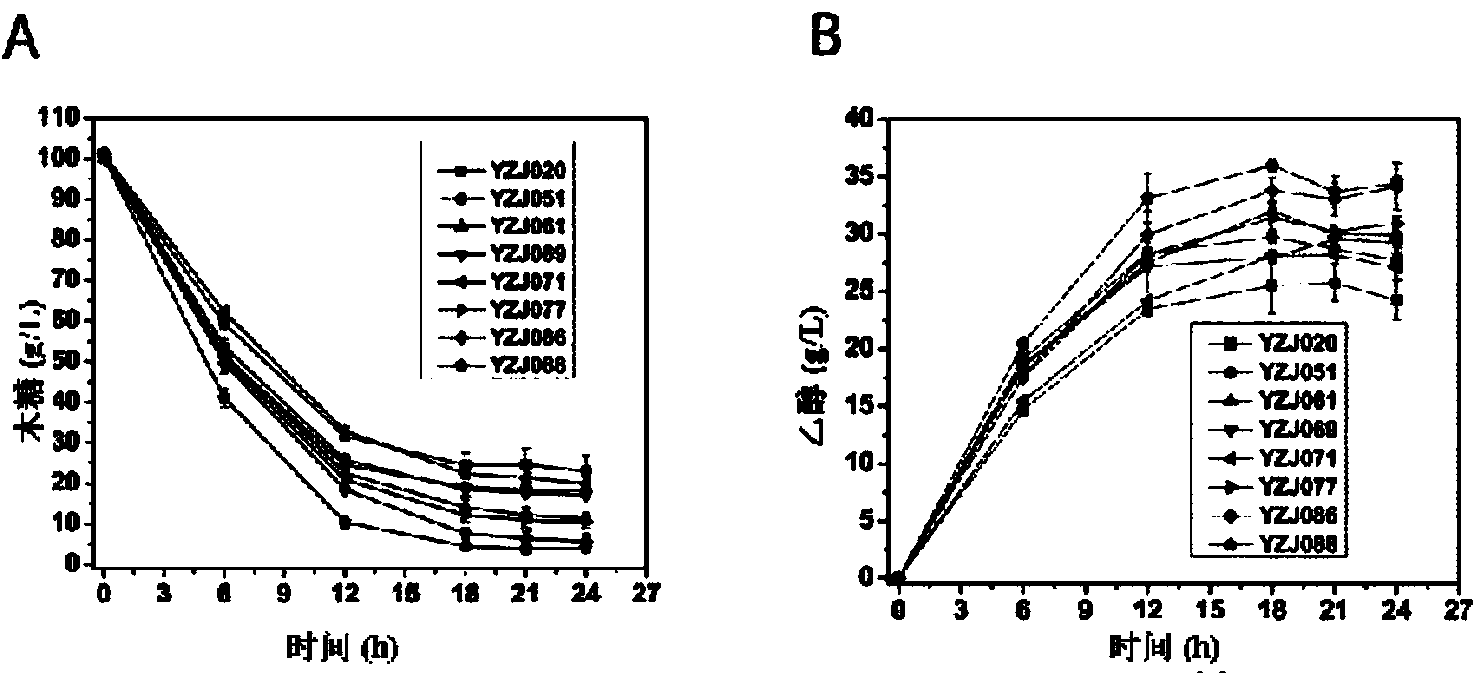

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be described in further detail below. It should be noted that the various embodiments of the present invention can be combined in any way as desired.

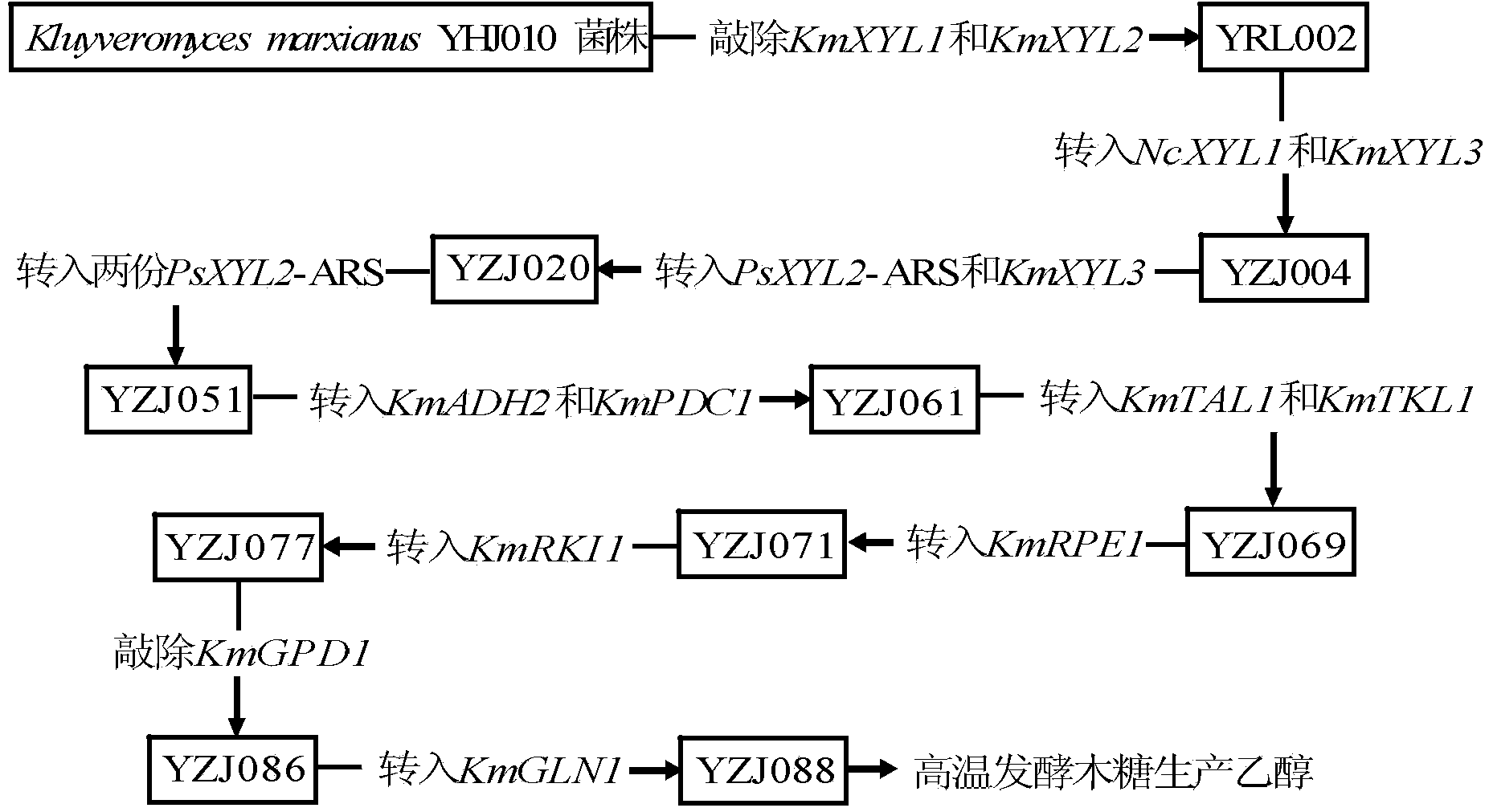

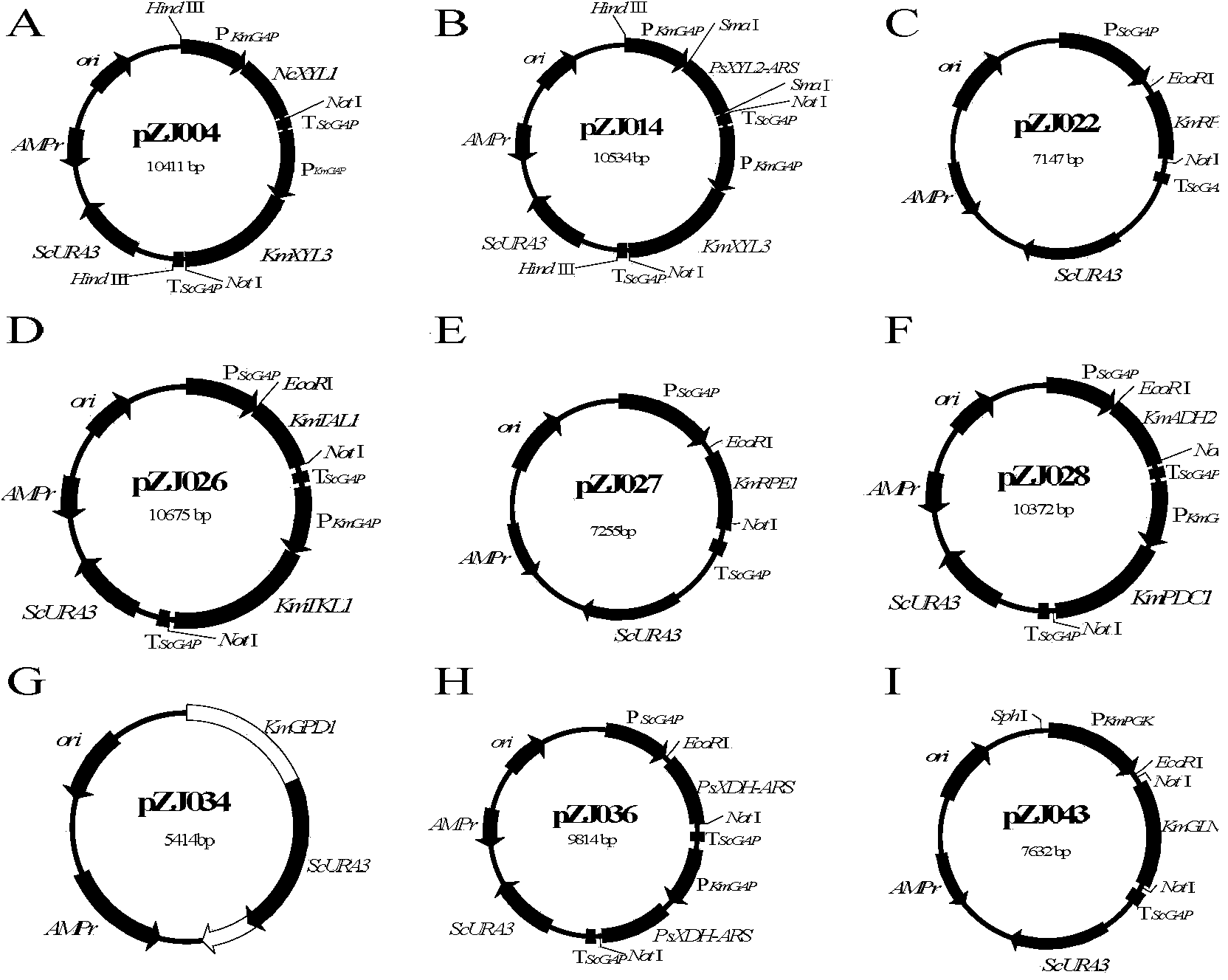

[0024] The first aspect of the present invention provides a heat-resistant engineering yeast strain that can efficiently utilize xylose for fermentation. In one embodiment, the bacterial strain is obtained by the following method: using the heat-resistant yeast K. marxianus strain with knockout of xylose reductase gene and xylitol dehydrogenase gene as host, and NcXYL1, PsXYL2-ARS, KmXYL3 was recombinantly expressed in the host.

[0025] In a preferred embodiment, the strain contains the xylitol reductase gene NcXYL1 of Neurospora crassa.

[0026] In a preferred embodiment, the mutant gene PsXYL2-ARS has a D207A / I208R / F209S mutation on the basis of the wild-type xylitol dehydrogenase gene.

[0027] In a preferred embodiment, the strain contains two copies of the mut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com