Application of sodium butyrate to preparation of feed or feed additive of promoting flaudio-videoonoid secretion

A feed additive, sodium butyrate technology, applied in the direction of animal feed, animal feed, application, etc., can solve the problems of unfavorable popularization, poor dispersion, loss and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] 1 Materials and methods

[0017] 1.1 Test material

[0018] Dihydropyridine and coated slow-release sodium butyrate (trade name: Uptin, sodium butyrate content 30%) are provided by Hangzhou Kangdequan Feed Co., Ltd., and the specific preparation method refers to the method disclosed in CN103238730A;

[0019] Experimental animals: 96 Du long-term three-way hybrid sows (body weight 75kg).

[0020] 1.2 Feeding management: The experimental pigs were fed in groups, fed adequately, 3 times a day, and had free access to water. The pre-trial period was 7 days, and the rats were fed with basal diets, and the main trial period was 28 days.

[0021] 1.3 Test time: 2010.3-2010.4

[0022] 1.4 Test site: Zhejiang Academy of Agricultural Sciences Pig Breeding Farm

[0023] 1.5 Experimental design:

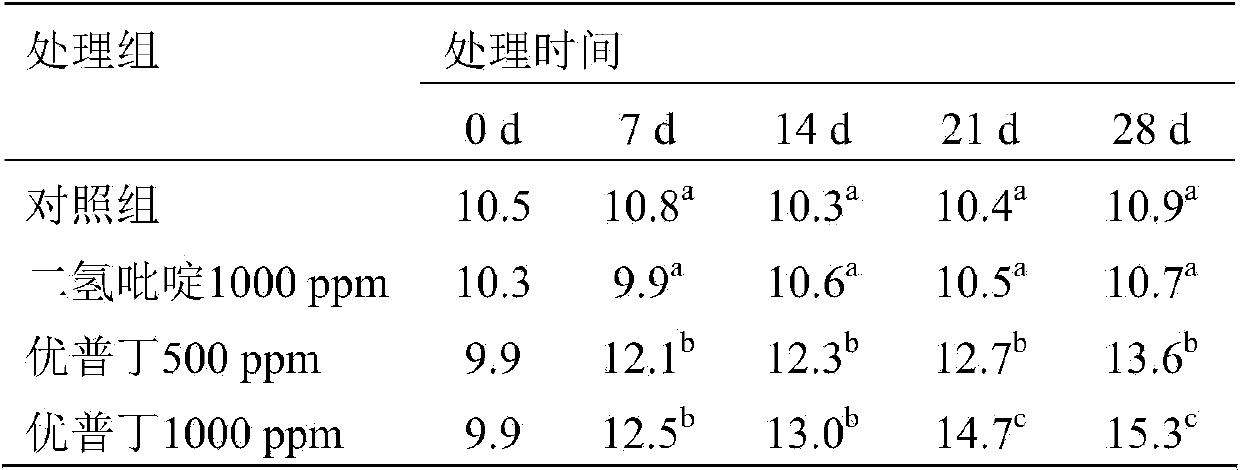

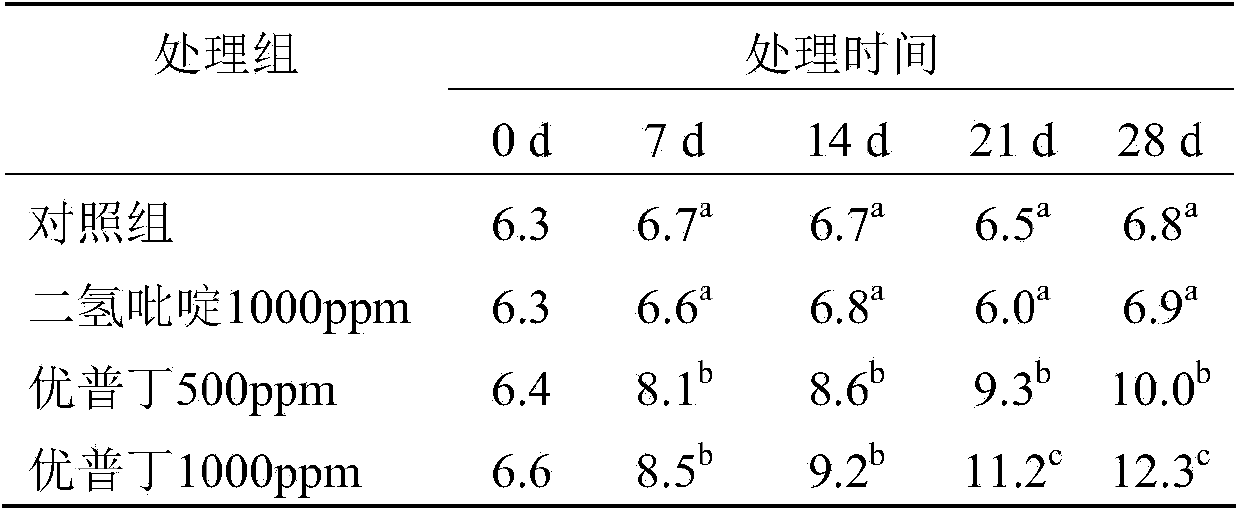

[0024] 96 test sows were randomly divided into four groups, namely control group, test I group, test II group and test III group, each handling 6 repetitions (columns), and each repet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com