Chicken-flavor seasoning powder and preparation method and application thereof

A technology of seasoning powder and chicken flavor, applied in the field of food seasoning, can solve the problems of destroying the original flavor of food, poor improvement effect, excessive usage, etc., and achieve the effect of fine and smooth entrance, improved flavor and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

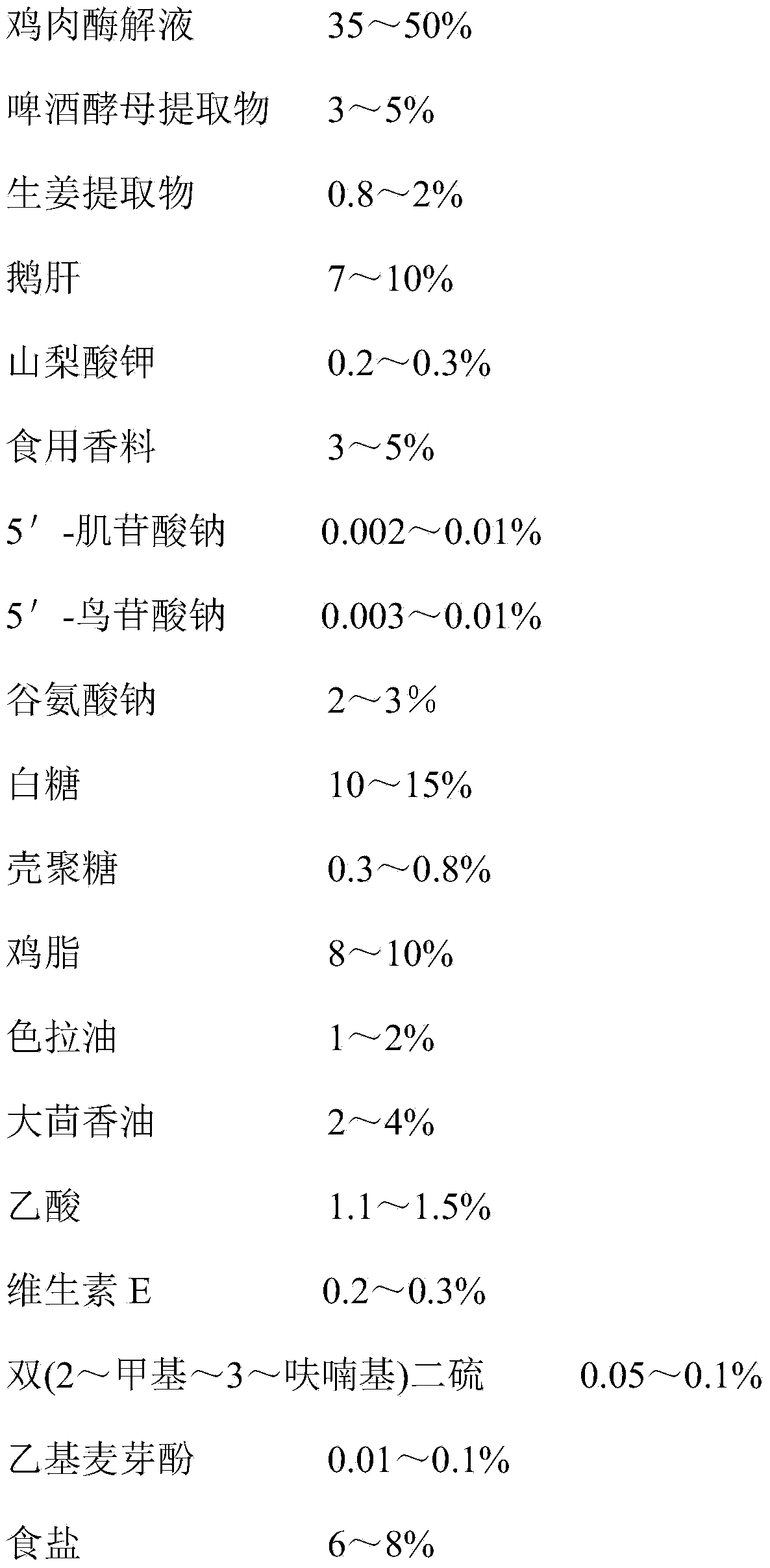

Method used

Image

Examples

Embodiment 1

[0045] The chicken enzymatic hydrolyzate is firstly prepared, wherein the chicken enzymatic hydrolyzate is prepared by the following method: the chicken breast is boiled, then cut into pieces and pulverized to make the chicken breast powder. Add chicken breast meat powder: water into water at a weight ratio of 1:0.7~1.3, heat and control the temperature between 50~57°C, add compound flavor protease (Flavourzyme) to hydrolyze 1~0.8% chicken breast meat powder by weight 1.5 hours. Then separate and remove slag, heat and concentrate, and concentrate to remove 20% of water. Of course, the present invention does not need to limit the degree of concentration here.

[0046] Here the temperature must be selected between 50-57°C, and 1-1.5 degrees of hydrolysis is enough, not only the efficiency is high, but also the degree of enzymatic hydrolysis is thorough. If the temperature is below 50°C, the enzymatic hydrolysis efficiency of the compound flavor protease is very high, which will...

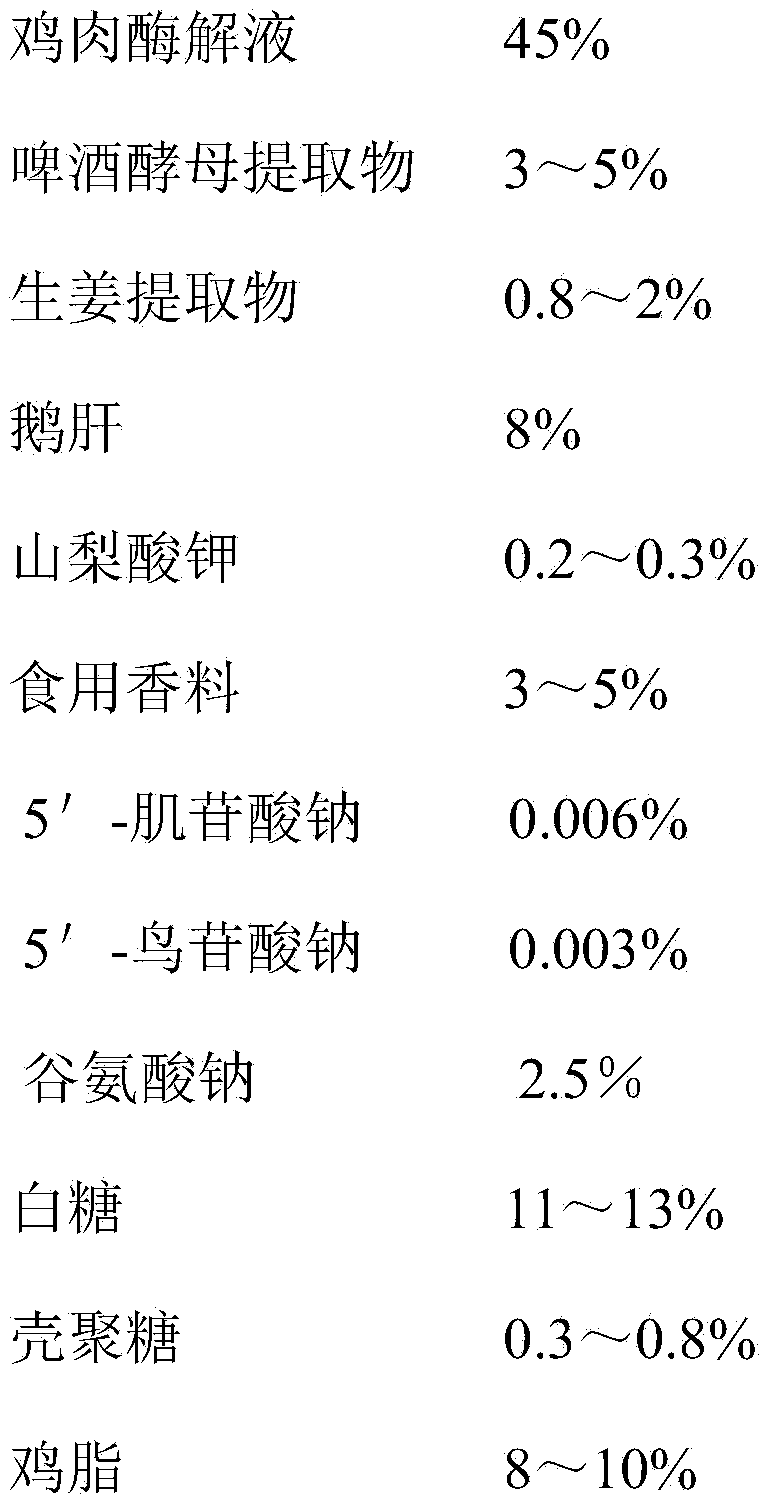

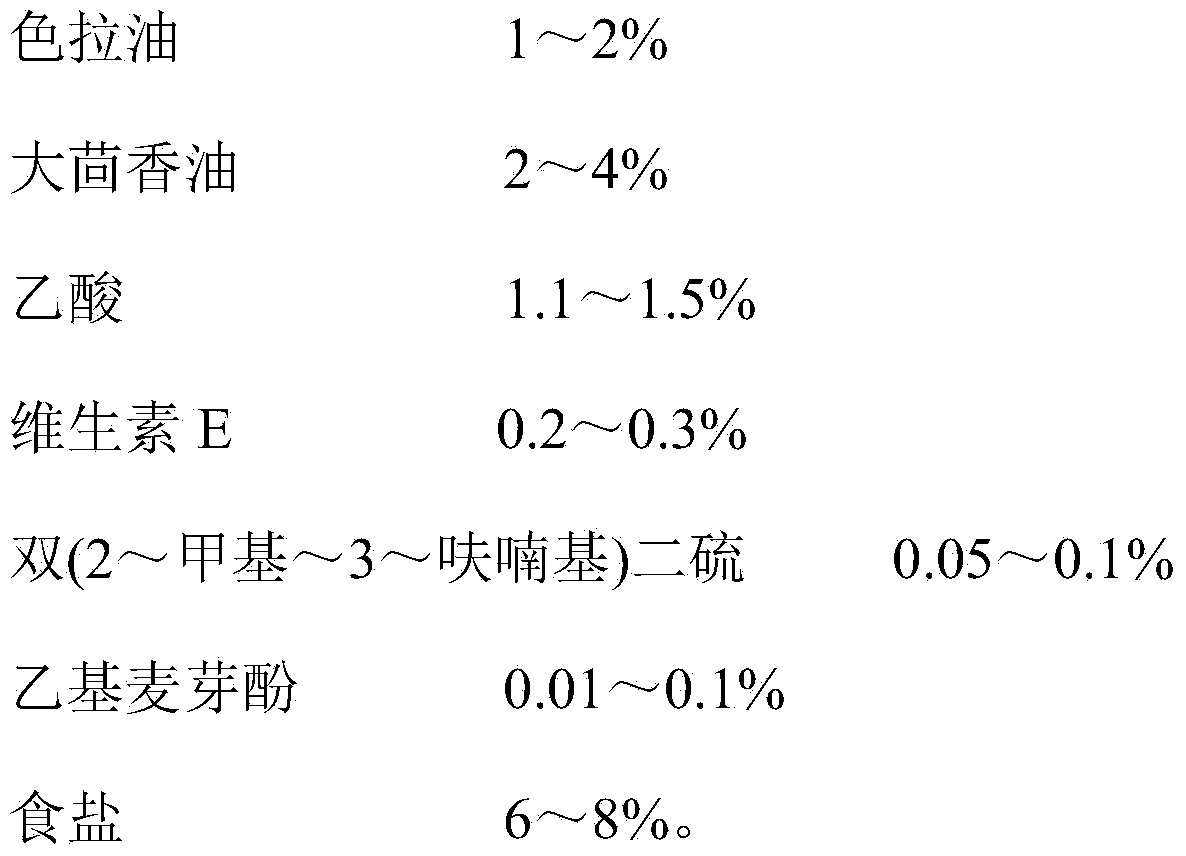

Embodiment 2

[0051] The raw materials of the present embodiment are based on percentage by weight, and what get is 45% chicken enzymatic hydrolyzate, 5% brewer's yeast extract, 0.83% ginger extract, 8% foie gras, 0.26% potassium sorbate, 4 % of food flavoring, 0.005% of 5'-sodium inosinate, 0.003% of 5'-sodium guanylate, 2.6% of sodium glutamate, 10% of white sugar, 0.72% of chitosan, 9% of Chicken fat, 2% salad oil, 3% anise oil, 1.2% acetic acid, 0.25% vitamin E, 0.062% bis(2-methyl-3-furyl) disulfide, 0.07% ethyl malt Phenol and 8% table salt are used as raw materials, and the total raw materials are 100%. All the other repeat Example 1.

Embodiment 3

[0053] The raw material of present embodiment is according to weight percent, and what get is 48% chicken enzymolysis solution, 3% brewer's yeast extract, 1% ginger extract, 8.25% foie gras, 0.25% potassium sorbate, 3 % food flavoring, 0.003% of 5'-sodium inosinate, 0.004% of 5'-sodium guanylate, 2% of sodium glutamate, 12% of white sugar, 0.75% of chitosan, 9.2% of Chicken fat, 1.3% salad oil, 2.5% anise oil, 1.4% acetic acid, 0.2% vitamin E, 0.08% bis(2-methyl-3-furyl) disulfide, 0.063% ethyl malt Phenol and 7% table salt are used as raw materials, and the total raw materials are 100%. All the other repeat Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com