Food detoxification machine and detoxification method

A detoxification machine, food technology, applied in food preservation, food processing, food science and other directions, can solve the problems of low detoxification efficiency, health hazards, hindering bacterial metabolism and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

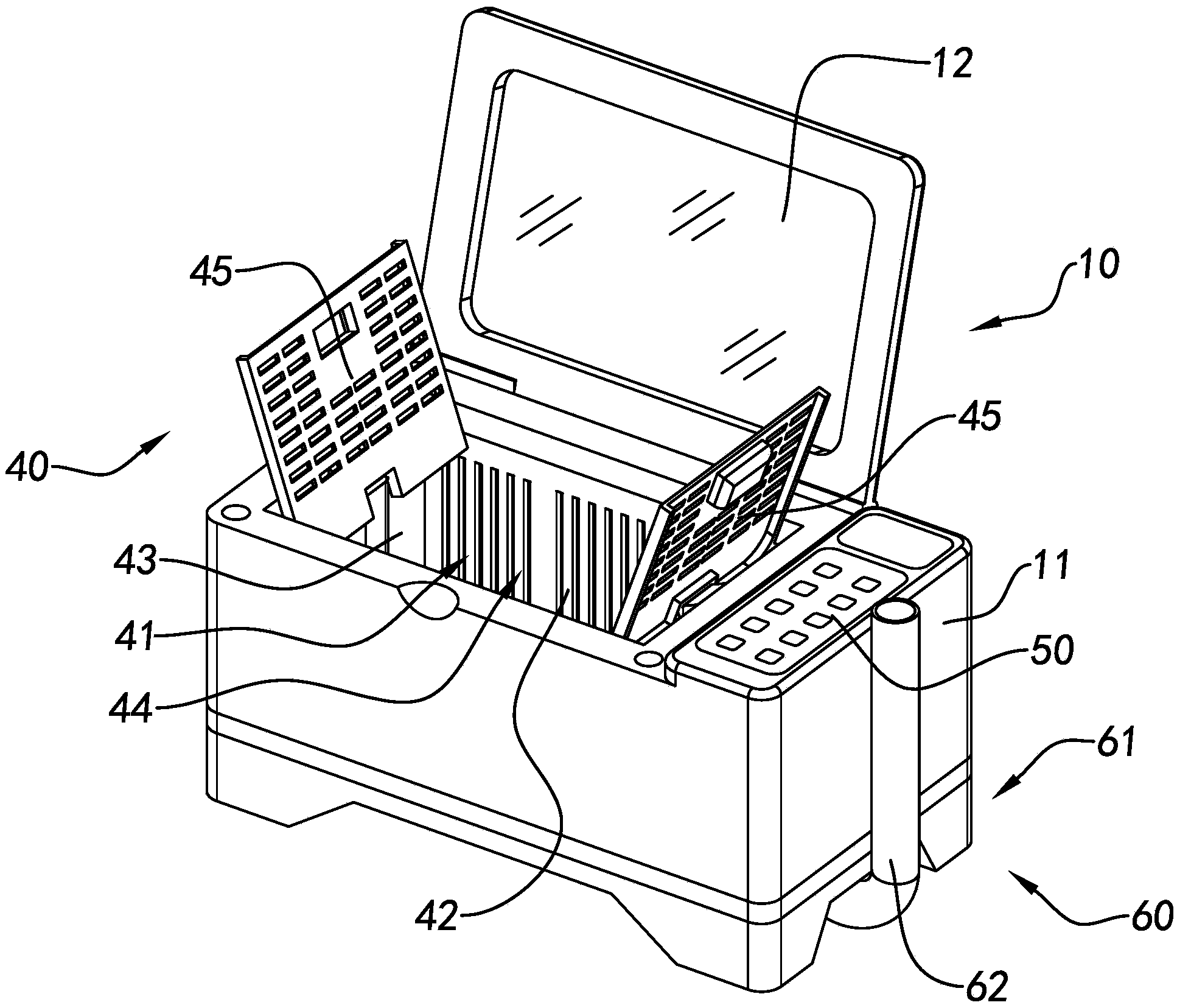

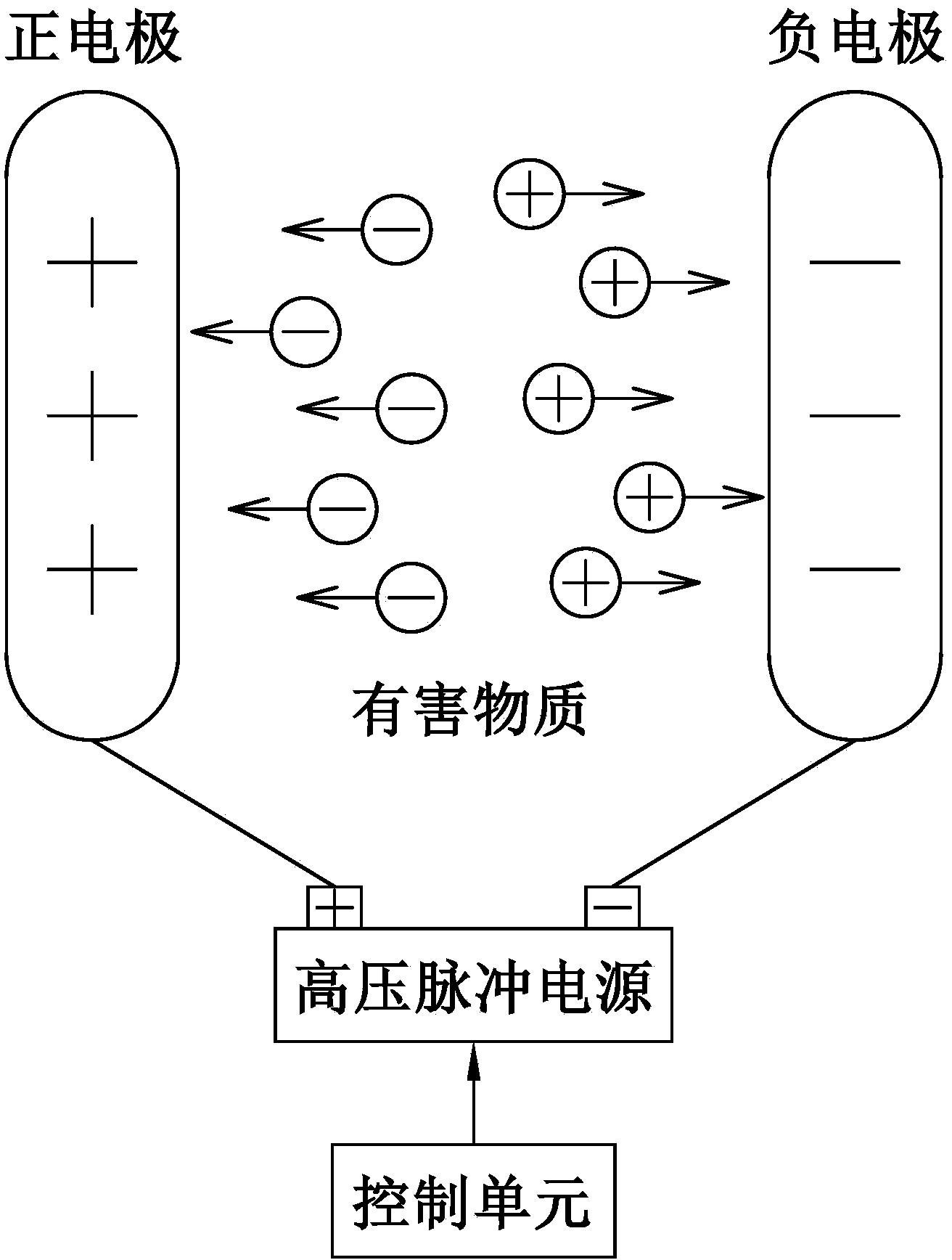

[0075] like Figure 4 As shown, a pair of electrodes 32 are installed on the bottom 44 of the processing chamber 40, wherein the positive and negative electrodes of the electrodes 32 are respectively connected to the positive and negative electrodes of the high-voltage pulse power supply 31, and the user passes Operate the control unit 50 to start the high-voltage pulse power supply 31, and an instantaneous high-voltage pulse electric field is formed between the electrodes 32, filling the cavity 41, and removing food such as fruits and vegetables placed in the cavity 41. Poison treatment.

[0076] It is worth mentioning that more than two pairs of electrodes 32 can be installed on the bottom 44 .

Embodiment 2

[0078] like Figure 5 As shown, two pairs of electrodes 32 are installed on the front and rear walls 42 of the processing chamber 40, wherein the positive and negative electrodes of the two pairs of electrodes 32 are respectively connected to the positive and negative electrodes of the high-voltage pulse power supply 31, The user activates the high-voltage pulse power supply 31 by operating the control unit 50, and an instantaneous high-voltage pulse electric field is formed between the electrodes 32, which fills the cavity 41 and affects the fruits and vegetables placed in the cavity 41. Food is detoxified.

[0079] It is worth mentioning that the front and rear walls 42 can also be equipped with one pair or more than three pairs of the electrodes 32, and the electrodes 32 can be installed at any position of the front and rear walls 42, that is, they can be close to the front and rear walls. The top, middle and bottom edges of 42, preferably the middle and bottom edges in th...

Embodiment 3

[0081] like Image 6 As shown, two pairs of electrodes 32 are respectively installed on the front and rear walls 42 and the side walls 43 of the processing chamber 40, wherein the positive and negative electrodes of the electrodes 32 are respectively connected to the positive and negative electrodes of the high-voltage pulse power supply 31. , negative pole, the user operates the control unit 50 to start the high-voltage pulse power supply 31, and an instantaneous high-voltage pulse electric field is formed between the electrodes 32, which fills the cavity 41 and is placed in the cavity Foods such as fruits and vegetables in 41 are detoxified.

[0082] It is worth mentioning that the front and rear walls 42 and the side walls 43 can also be installed with one pair or more than three pairs of the electrodes 32, and the electrodes 32 can be installed on the front and rear walls 42 and the side walls. 43, that is, it can be installed on the top edge, the middle part and the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com