Heterogeneous catalyst for selective hydrogenation reaction of aryl nitro-compound and application of heterogeneous catalyst

A technology of aromatic nitro compounds and heterogeneous catalysts, which is applied in the preparation of amino compounds, organic compounds, physical/chemical process catalysts, etc. It can solve the problems of easy deactivation, low selectivity, and limited catalyst application, etc., to achieve The effect of easy product structure, good dispersion and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

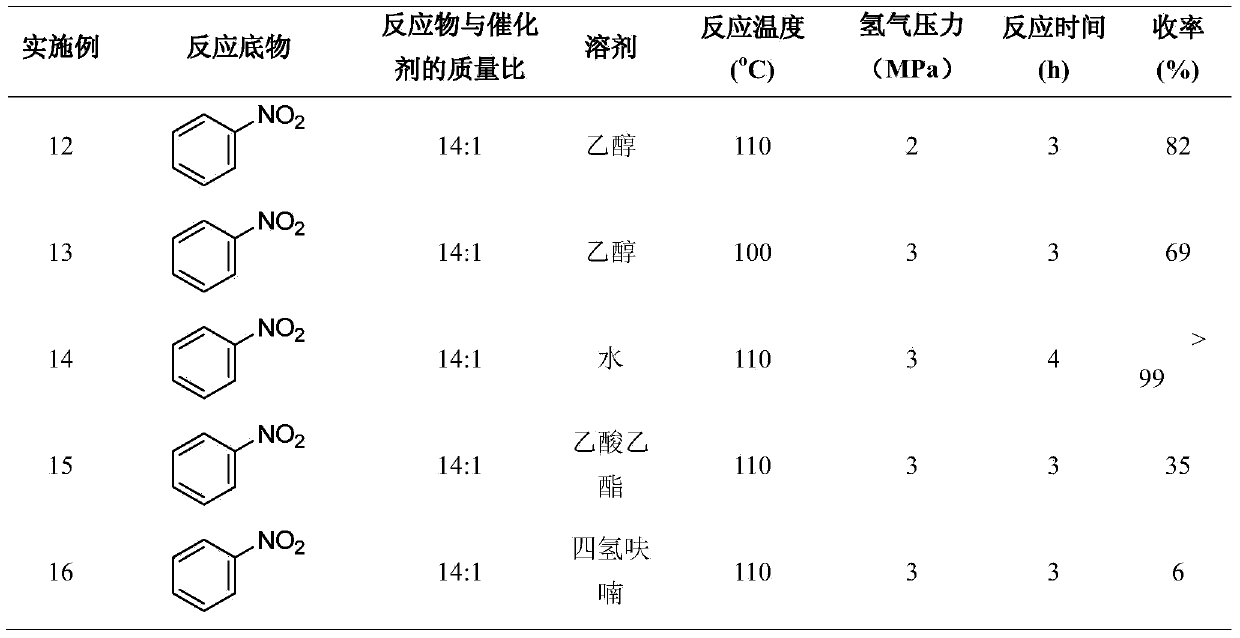

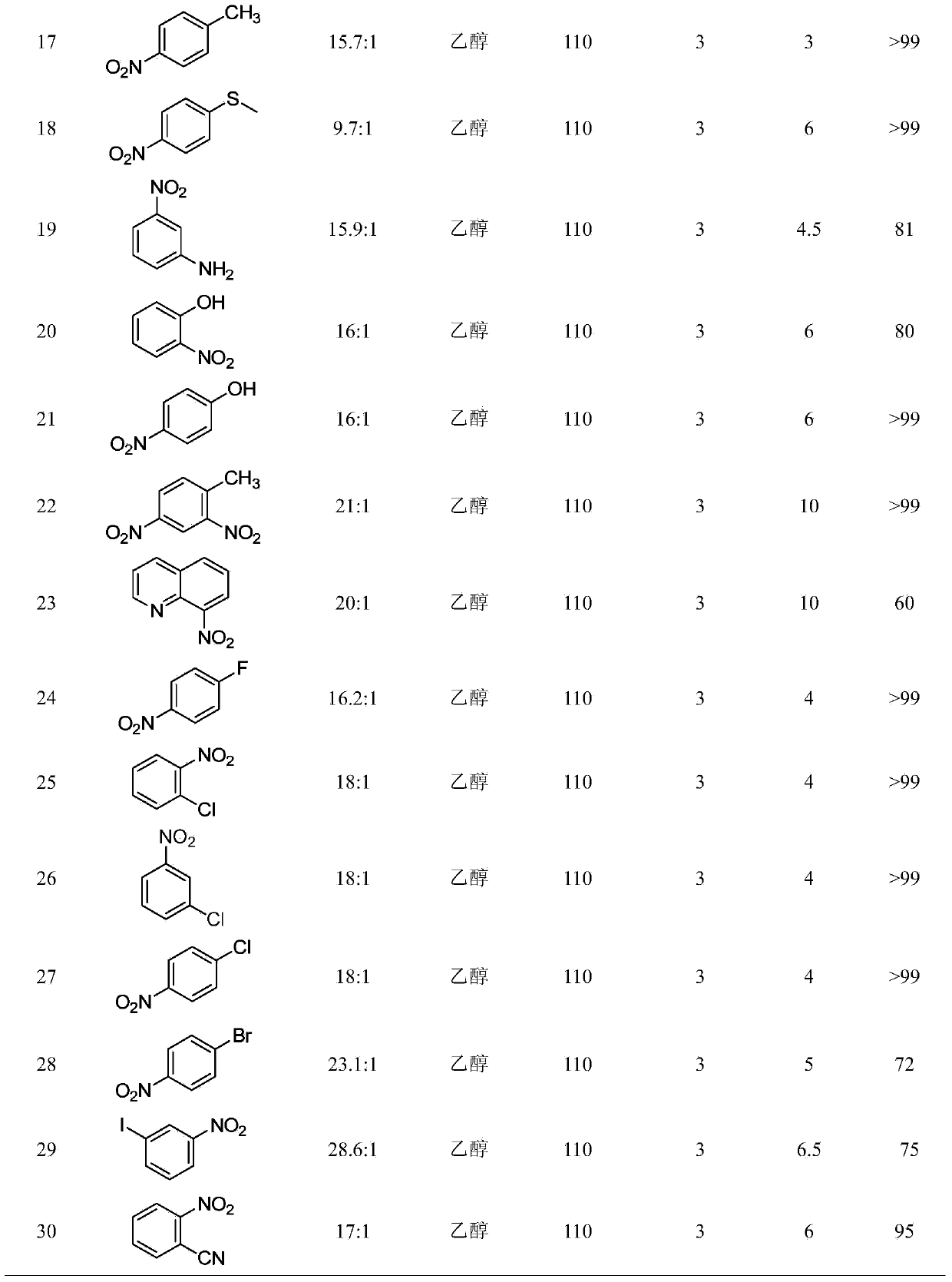

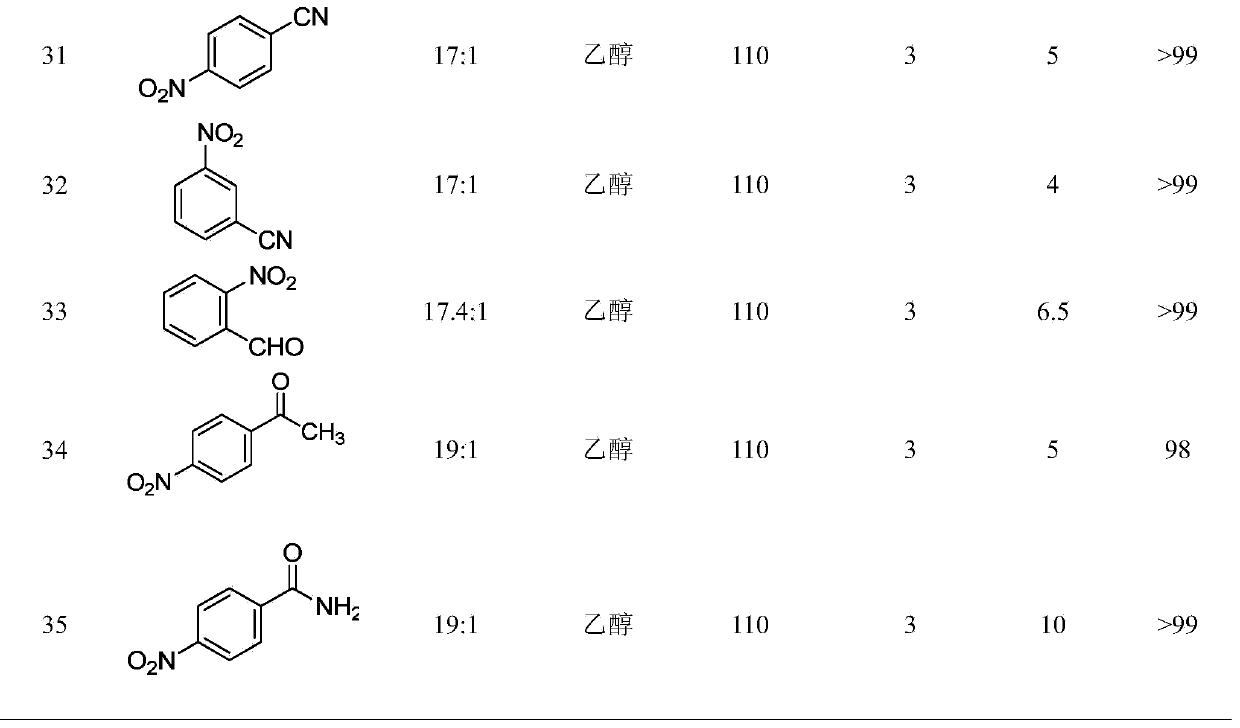

Examples

Embodiment 1

[0026] Example 1 Heterogeneous catalyst based on Fe and nitrogen doped carbon nanotubes

[0027] Add 1g of glucosamine hydrochloride and 200ml of deionized water into a 250ml beaker, stir to dissolve, then add 1.6g of ferric nitrate, and stir until a uniform solution. Add 20g melamine then, dissolve in the above-mentioned glucosamine hydrochloride solution. Heat and stir until the deionized water is completely volatilized to obtain a solid mixture. After the mixture is calcined in a nitrogen furnace through a two-stage heating program (600°C for 1h and 900°C for 1h), the FeO with a composition of 26wt% is obtained. x (0<x<1.5) and 74wt% nitrogen-doped carbon nanotube hybrid catalyst, wherein the nitrogen content is about 2.0wt%.

Embodiment 2

[0028] Example 2 Heterogeneous catalyst based on Co and nitrogen doped carbon nanotubes

[0029] Add 1g of glucosamine hydrochloride and 200ml of deionized water into a 250ml beaker, stir to dissolve, then add 0.95g of cobalt nitrate, and stir to a uniform solution. Then add 40g of melamine, dissolved in the above-mentioned glucosamine hydrochloride solution. Heat and stir until the deionized water is completely volatilized to obtain a solid mixture. After the mixture is calcined in a nitrogen furnace through a two-stage heating program (600°C for 1h and 800°C for 1h), a CoO with a composition of 28wt% is obtained. x (0<x<1.3) and 72wt% nitrogen-doped carbon nanotube hybrid catalyst, wherein the nitrogen content is about 2.0wt%.

Embodiment 3

[0030] Example 3 Heterogeneous catalyst based on Co and nitrogen doped carbon nanotubes

[0031] Add 1g of glucosamine hydrochloride and 200ml of deionized water into a 250ml beaker, stir to dissolve, then add 0.95g of cobalt nitrate, and stir to a uniform solution. Add 20g melamine then, dissolve in the above-mentioned glucosamine hydrochloride solution. Heat and stir until the deionized water is completely volatilized to obtain a solid mixture. After the mixture is calcined in a nitrogen furnace through a two-stage heating program (600°C for 1h and 900°C for 1h), a CoO with a composition of 31wt% is obtained. x (0<x<1.3) and 69 wt% nitrogen-doped carbon nanotube hybrid catalyst, wherein the nitrogen content is about 2.0 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com