Method for preparing total potassium W type molecular sieve by activating potassium feldspar via KOH sub-molten salt

A technology for activating potassium feldspar and sub-molten salt, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of increasing process cost, difficulty in operability, complicated system processing, poor system fluidity, etc., and saves energy and raw materials. Wide source, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

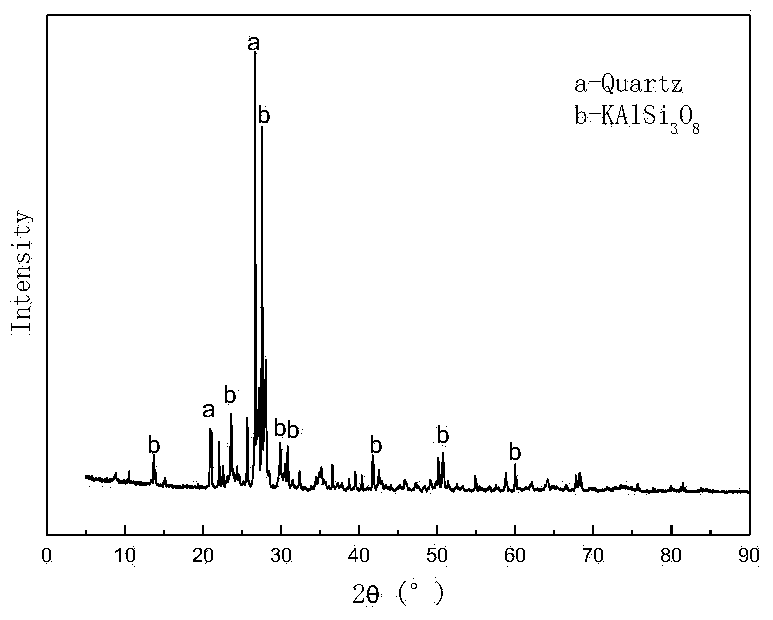

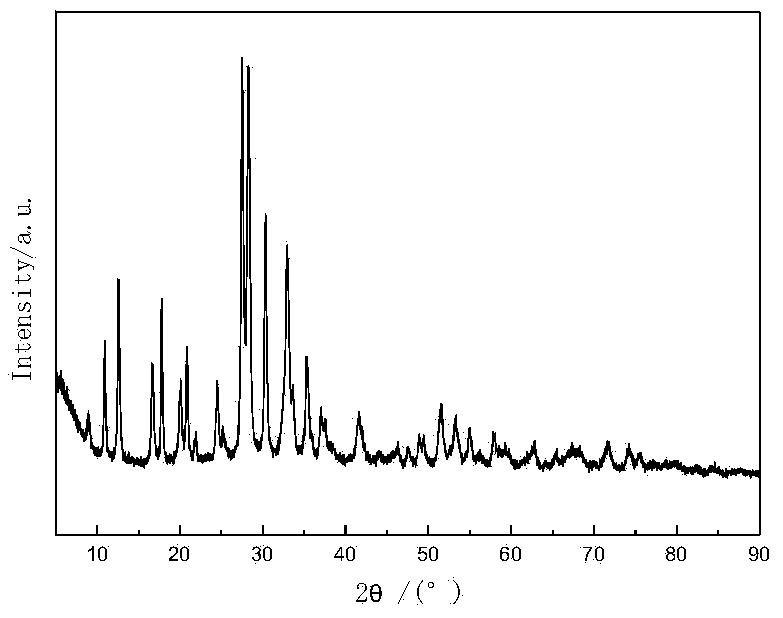

[0039] (1) Activation and preparation

[0040] KOH (purity is 85%) 35.2943g, water 7.5ml join in the there-necked bottle and mix evenly, make initial alkali concentration namely KOH mass concentration be 70%, then potassium feldspar ore powder 9.9998g is joined in the there-necked bottle and KOH and Mix the water evenly so that the mass ratio of mineral alkali to potassium feldspar:KOH=1:3. The mixed system was placed in an oil bath at 160° C., stirred, condensed and refluxed for activation reaction for 5 hours.

[0041] (2) Aging

[0042] SiO in the activated system 2 and Al 2 o 3 The content is SiO in potassium feldspar 2 and Al 2 o 3 content, K 2 O content is K in potassium feldspar 2 The dissolved amount of O is converted into K from KOH 2 After O (the conversion formula is ) content. The activated system is according to the molar ratio of SiO 2 / Al 2 o 3 =12,K 2 O / SiO 2 =1.6,H 2 O / SiO 2 =51, add silicon source (white carbon black - that is, SiO 2 , (the...

Embodiment 2

[0050] (1) Activation and preparation

[0051] KOH (purity is 85%) 35.2943g, water 4.7ml join in the there-necked bottle and mix evenly, make initial alkali concentration namely KOH mass concentration be 75%, then join potassium feldspar ore powder 10.0006g in the there-necked bottle and mix with KOH and Mix the water evenly so that the mass ratio of mineral alkali to potassium feldspar:KOH=1:3. The mixed system was placed in an oil bath at 160° C., stirred, condensed and refluxed for activation reaction for 5 hours.

[0052] (2) Aging

[0053] The system after activation in (1) is according to the ratio of SiO 2 / Al 2 o 3 =12,K 2 O / SiO 2 =1.6,H 2 O / SiO 2 =51, add 3.3156g of silicon source (white carbon black), 0.0982g of aluminum hydroxide and 143.56ml of water, and stir evenly. The mixture was mechanically stirred at 25 °C for 3 h.

[0054] (3) Crystallization

[0055] Put the mixed solution obtained in step (2) into a closed crystallization kettle, and crystalliz...

Embodiment 3

[0061] (1) Activation and preparation

[0062] KOH (purity is 85%) 35.2943g, water 4.7ml join in the there-necked bottle and mix evenly, make initial alkali concentration namely KOH mass concentration be 75%, then join potassium feldspar ore powder 10.0004g in the there-necked bottle and mix with KOH and Mix the water evenly so that the mass ratio of mineral alkali to potassium feldspar:KOH=1:3. The mixed system was placed in an oil bath at 140° C., stirred, condensed and refluxed for activation reaction for 5 hours.

[0063] (2) Aging

[0064] The system after activation in (1) is according to the ratio of SiO 2 / Al 2 o 3 =12,K 2 O / SiO 2 =1.6,H 2 O / SiO 2 =51, add 3.3423g of silicon source (white carbon black), 0.1370g of aluminum hydroxide and 143.54ml of water, and stir evenly. The mixture was mechanically stirred at 25 °C for 3 h.

[0065] (3) Crystallization

[0066] Put the mixed solution obtained in step (2) into a closed crystallization kettle, and crystalliz...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap