Method for preparing titanium deuteride by high-temperature direct process

A technology of deuterated titanium and direct method, which is applied in the interdisciplinary field of materials science and nuclear technology, can solve the problems of low product purity and incapable large-scale preparation of deuterated titanium, and achieve the effects of safe and stable storage, easy operation and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

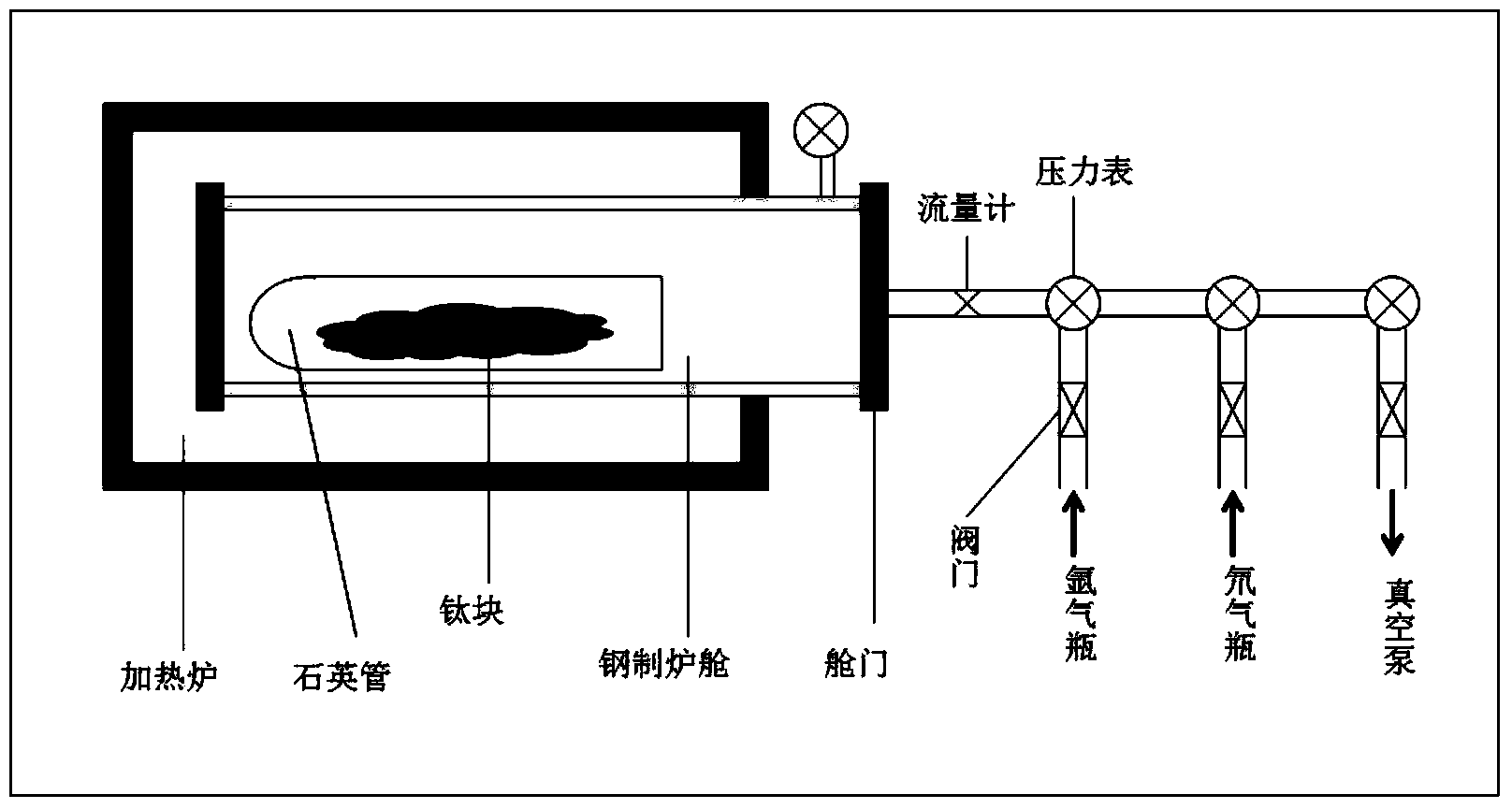

[0023] Under the protection of argon, wash a titanium block with a particle size of 2 mm and a purity of 99.99% in 40% sodium hydroxide solution at 70°C for 20 minutes, wash it with deionized water for 4 times, and dry it in vacuum; weigh 700g and put it into quartz glass tube, and placed in the high-temperature heating furnace cabin, quickly close the furnace cabin, such as figure 1 As shown; after replacing the gas in the heating furnace cabin with argon, the pressure in the cabin is pumped to a negative pressure of 0.024MPa, and then 99.999% high-purity deuterium gas is introduced to the normal pressure state. After repeated operations for 3 times, the cabin is kept at Negative pressure state: quickly raise the temperature in the furnace cabin to 481°C at a heating rate of 30°C / min, and then introduce high-purity deuterium gas, and control the flow rate at 2406ml / min. After 40 minutes of reaction, continue to Speed up the temperature for 36 minutes to 783°C, stop heating,...

Embodiment 2

[0025] Under the protection of argon, wash the titanium block with a particle size of 10 mm and a purity of 99.99% in 40% sodium hydroxide solution at 50°C for 45 minutes, and after washing with deionized water for 7 times, dry it in vacuum; weigh 2000g, and put it into quartz glass and put it in the high-temperature heating furnace cabin, and quickly close the furnace cabin; after replacing the gas in the heating furnace cabin with argon, the pressure in the cabin is pumped to a negative pressure of 0.015MPa, and then 99.999% high-purity deuterium gas is introduced to normal After repeated operations for 3 times, keep the cabin in a negative pressure state; quickly raise the temperature in the furnace cabin to 458°C at a heating rate of 40°C / min, inject high-purity deuterium gas, and control the flow rate to 4674ml / min. Change, after 48 minutes of reaction, continue to raise the temperature at a rate of 10°C / min for 47 minutes to 776°C, stop heating, keep the temperature and d...

Embodiment 3

[0027]Under the protection of argon, boil a titanium block with a particle size of 2mm and a purity of 99.99% in ethanol for 30 minutes, then wash it in 98% concentrated sulfuric acid at 80°C for 20 minutes, wash it 5 times with deionized water, and dry it in vacuum; weigh 750g , into a quartz glass tube, and placed in a high-temperature heating furnace cabin, and quickly close the furnace cabin; after replacing the gas in the heating furnace cabin with argon, pump the pressure in the cabin to a negative pressure of 0.020MPa, and then introduce 99.999% high Pure deuterium gas is brought to the normal pressure state, and after repeated operations 3 times, the cabin is kept in a negative pressure state; the temperature in the furnace cabin is raised to 421 °C at a heating rate of 20 °C / min, and high-purity deuterium gas is introduced, and the flow rate is controlled to be 2972ml / min remains unchanged, after 42 minutes of reaction, continue to raise the temperature at a rate of 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com