Method for reducing pyrolysis activation energy of rice hulls

A technology of activation energy and rice husk, applied in the fields of biofuels, special forms of dry distillation, coke ovens, etc., can solve the problem of less degree of pyrolysis, and achieve the effect of no processing, simplified catalytic steps, and easy to obtain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

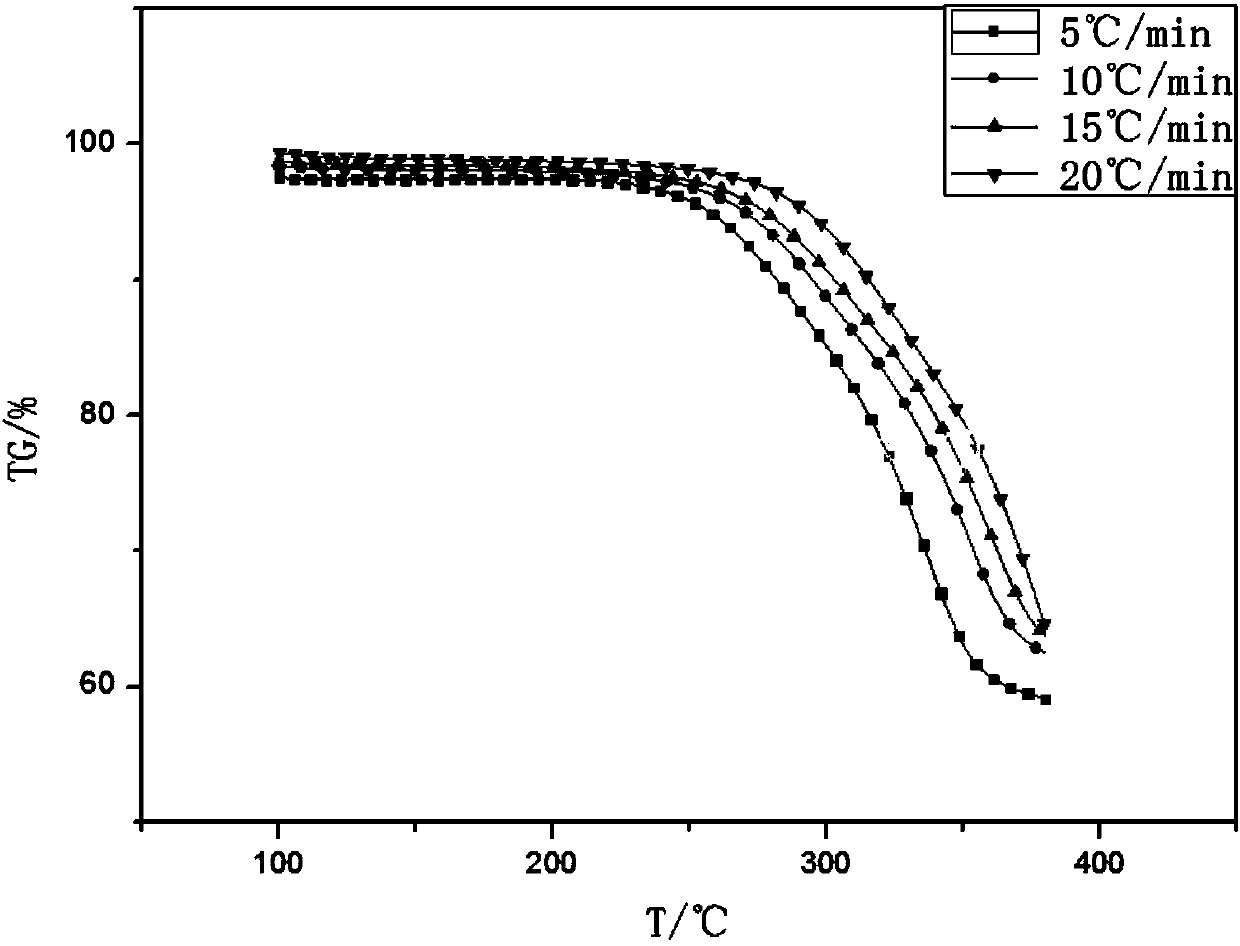

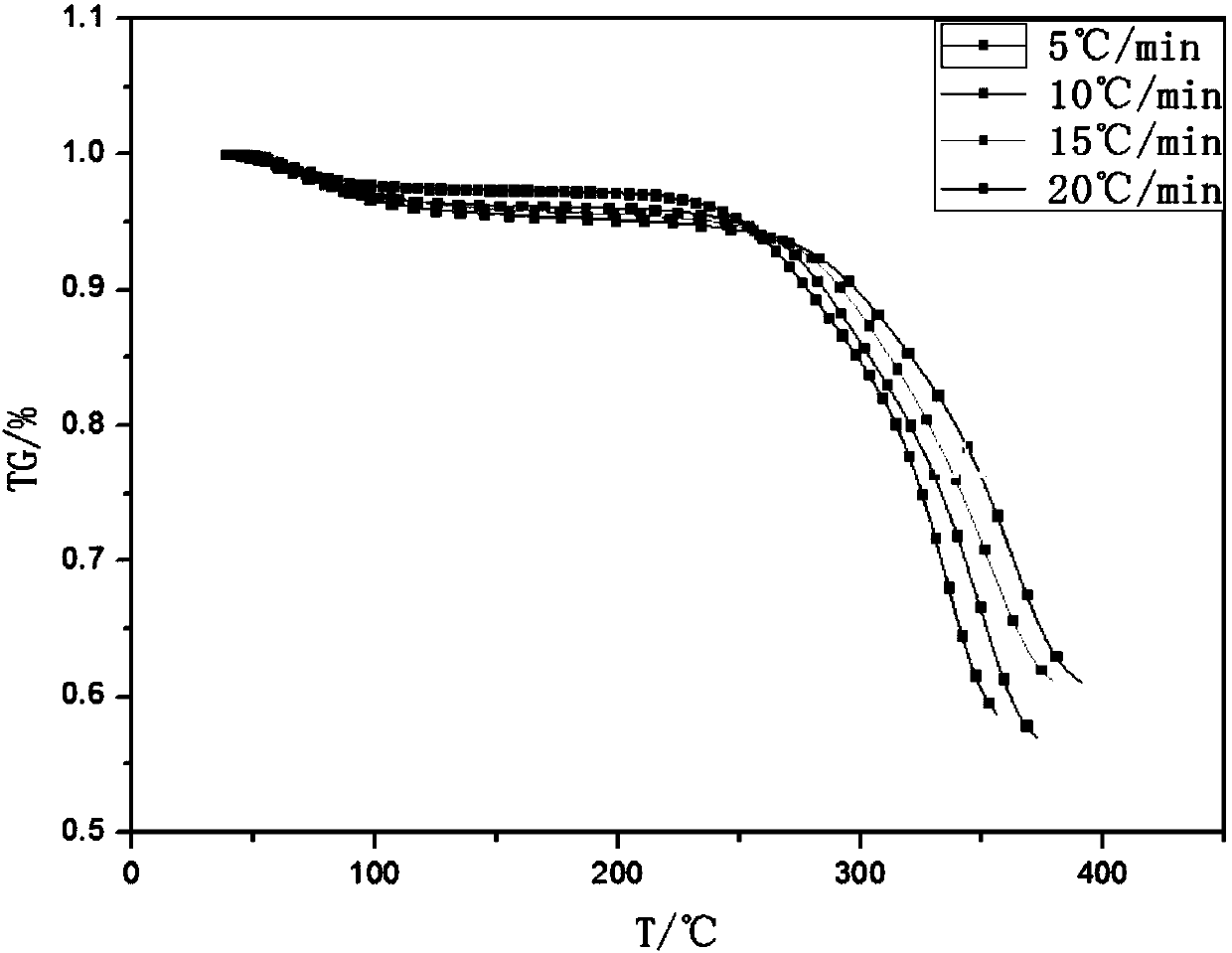

[0033] Prepare rice husks with a particle size of ≤1 mm, dry them at 105°C for 24 hours, weigh 5.0 mg of rice husks and 1 mg of alumina powder, mix them thoroughly, add them to a differential thermal balance, and use the non-isothermal method to separate them for 5 ℃ / min, 10℃ / min, 15℃ / min, 20℃ / min heat the sample to 1000℃, obtain the weight loss curve, and calculate the weight loss curve respectively, such as figure 1 and figure 2 .

[0034] From the comparison of the two figures, it can be seen that when the weight loss of pure rice husk reaches a stable level, the weight loss is about 59%-65%, and the temperature at this time is about 390°C, while the weight loss of rice husk catalyzed by alumina is about 59%-62%. , the lowest temperature is around 360°C. Experiments show that the addition of alumina can lower the pyrolysis temperature of rice husk, thereby reducing equipment requirements.

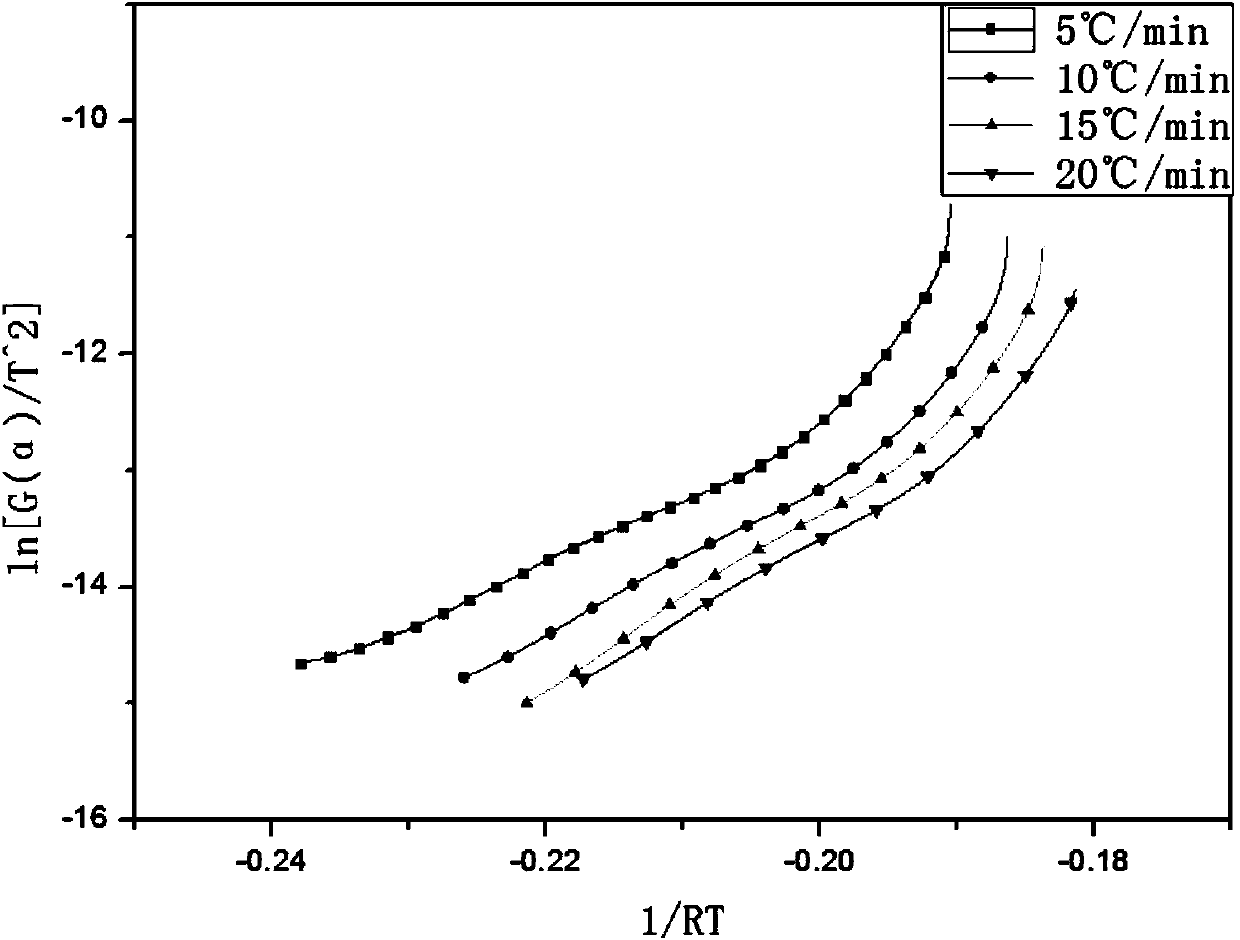

[0035] Use the Coats-Redfern method to calculate the activation energy before and...

Embodiment 2

[0038] Prepare rice husks with a particle size of ≤1 mm, dry them at 95°C for 16 hours, weigh 5.0 mg of rice husks and 2 mg of alumina powder, mix them thoroughly, add them to a differential thermal balance, and use the non-isothermal method to separate them for 5 ℃ / min, 10℃ / min, 15℃ / min, 20℃ / min heat the sample to 800℃, obtain the weight loss curve, and calculate the weight loss curve respectively.

Embodiment 3

[0040] Prepare rice husks with a particle size of ≤1 mm, dry them at 100°C for 20 hours, weigh 5.0 mg of rice husks and 1.5 mg of alumina powder, mix them thoroughly, add them to a differential thermal balance, and use the non-isothermal method to separate Heat the sample at 5°C / min, 10°C / min, 15°C / min, 20°C / min to 900°C, obtain the weight loss curve, and calculate the weight loss curve respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com