A kind of high-strength cu-ni-si alloy and preparation method thereof

A cu-ni-si, high-strength technology, applied in the field of copper alloy materials, can solve the problems of low alloy tensile strength and conductivity, low alloy strength and conductivity, and no strength data, etc., to slow down the recrystallization process, Resistant to grain segregation, strength and hardness improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

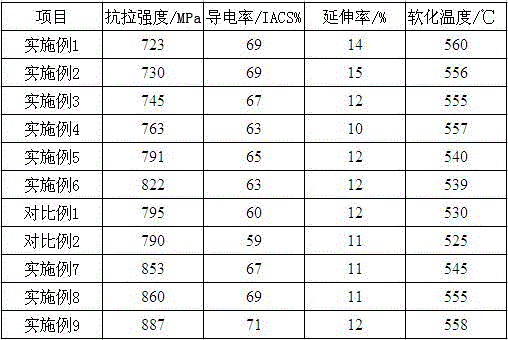

Examples

Embodiment 1

[0021] A high-strength Cu-Ni-Si alloy composed of the following components by weight percentage: 2.0% Ni, 0.52% Si, 0.53% Ti, 1.0% Mn, 1.0% Ag, and the balance is copper and Unavoidable impurity elements, and Ni is generated inside the alloy 2 Si non-oxide reinforcement phase.

[0022] The preparation method of above-mentioned high strength Cu-Ni-Si alloy is:

[0023] (1) Melting and mold casting: put the metal raw materials of the above components into a high-frequency vacuum melting furnace for melting, and vacuumize until the pressure in the furnace is 5×10 -2 Pa, and then fill the furnace with argon until the pressure in the furnace is 0.05MPa. The melting sequence is: add electrolytic nickel, silicon and part of copper → bake the material at 100 ° C for 15 minutes → heat up to melt copper, nickel, silicon → 1000 ° C Refining at low temperature for 10 minutes→increase the power and add titanium, manganese, silver (titanium, manganese and silver are all added in the form ...

Embodiment 2

[0030] A high-strength Cu-Ni-Si alloy composed of the following components by weight percentage: 2.5% Ni, 0.6% Si, 1.0% Ti, 0.7% Ag, 0.9% Mn, and the balance is copper and Unavoidable impurity elements, and Ni is generated inside the alloy 2 Si non-oxide reinforcement phase.

[0031] The preparation method of above-mentioned high strength Cu-Ni-Si alloy is:

[0032] (1) Melting and mold casting: put the metal raw materials of the above components into a high-frequency vacuum melting furnace for melting, and vacuumize until the pressure in the furnace is 5×10 -2 Pa, then fill the furnace with argon until the pressure in the furnace is 0.05MPa, the melting sequence is: add electrolytic Ni, Si and part of Cu → bake the material at 100°C for 15min → heat up to melt copper, nickel, silicon → 1000°C Refining at low temperature for 10min→increase the power and add Ti, Mn, Ag and the remaining Cu in the form of Ti-Cu, Mn-Cu and Ag-Cu master alloy→transmit electricity and raise the t...

Embodiment 3

[0039] A high-strength Cu-Ni-Si alloy composed of the following components by weight percentage: 2.5% Ni, 0.6% Si, 1.0% Ti, 0.7% Ag, 0.9% Mn, and the balance is copper and Unavoidable impurity elements, and Ni is generated inside the alloy 2 Si non-oxide reinforcement phase.

[0040] The preparation method of above-mentioned high strength Cu-Ni-Si alloy is:

[0041] (1) Refer to Example 2 for the smelting and casting mold preparation process; wherein, the smelting temperature is controlled at 1280°C during smelting, and the casting temperature is controlled at 1180°C;

[0042] (2) Homogenization treatment: heat the cast ingot obtained in step (1) to 990°C and keep it warm for 4 hours for homogenization annealing treatment;

[0043] (3) Hot-rolling deformation treatment: heat the ingot obtained in step (2) to 950°C, keep it warm for 10 minutes, and perform hot-rolling deformation treatment, and the hot-rolling rate is controlled at 0.1s -1 , 60% hot-rolled deformation, to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com