High-stability surface-enhanced Raman substrate and preparation method thereof

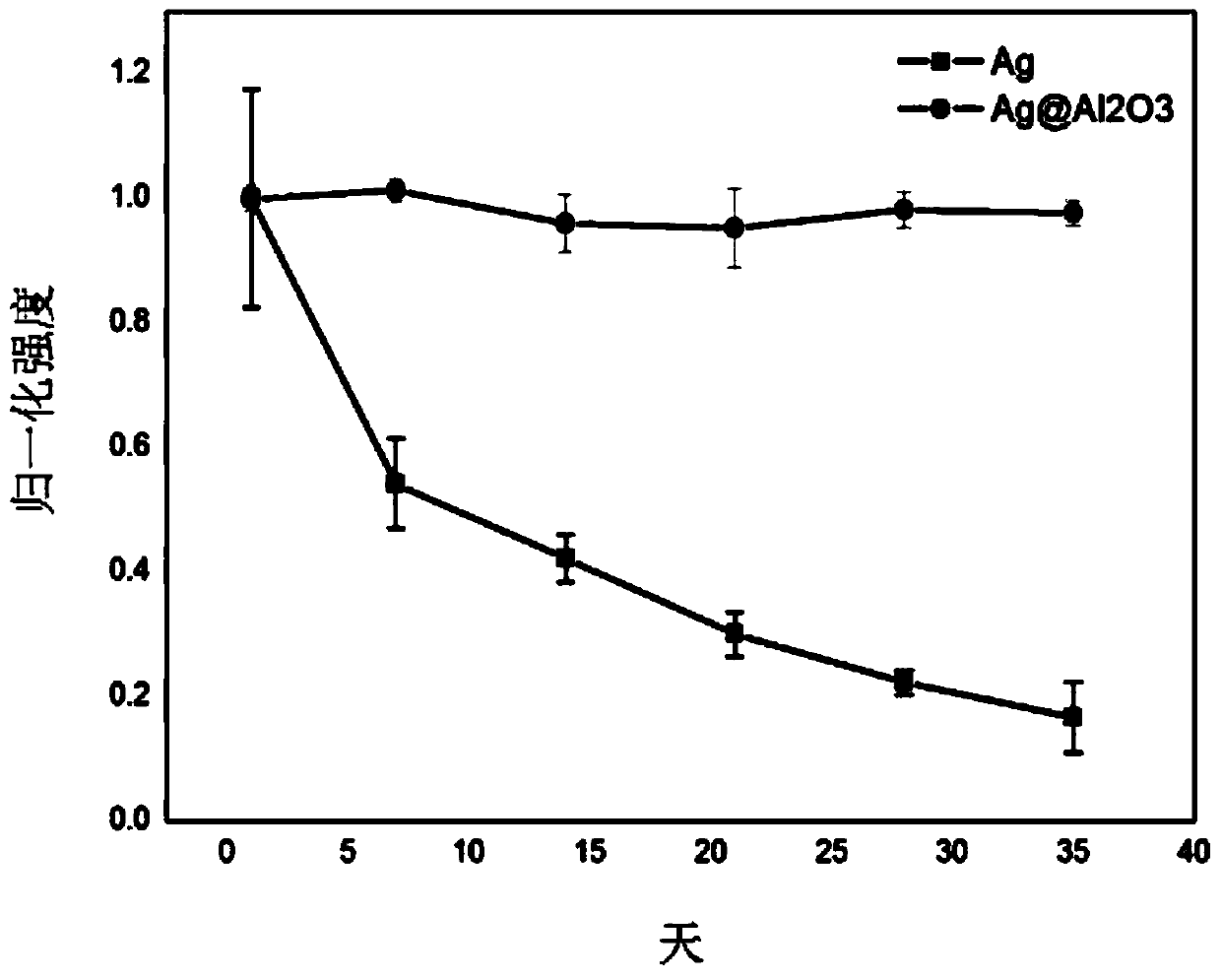

A surface-enhanced Raman, high-stability technology, used in Raman scattering, material excitation analysis, etc., can solve problems such as limitations, poor chemical stability, etc., to prevent oxidation, good surface-enhanced Raman effect, and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1. Clean the silicon substrate or glass substrate sequentially with acetone, alcohol and deionized water and dry them;

[0019] 2. Fix the pretreated substrate on the sample stage of the electron beam evaporation coating machine;

[0020] 3. At a temperature of 298K, using metallic silver as the target material, pump the chamber of the electron beam evaporation coating machine to 3×10 -5 Pa high vacuum;

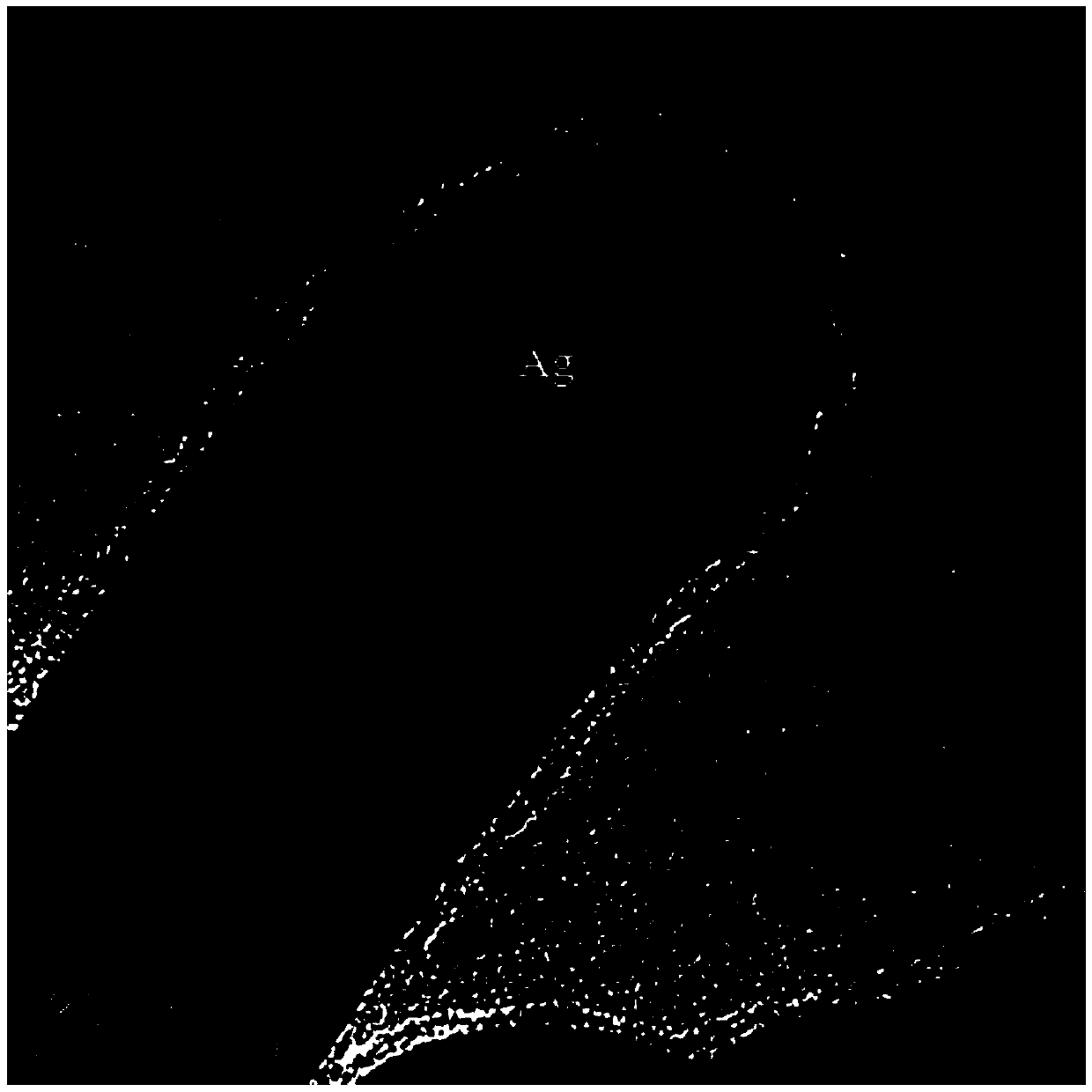

[0021] 4. Adjust the incident angle of the electron beam to 80 degrees, and make the sample stage static, and grow a 250nm thick silver deposition film obliquely on the base of the sample stage;

[0022] 5. By low-temperature atomic layer deposition method, a uniform and dense aluminum oxide film of 0.7nm is deposited on a silver substrate at 50°C to prepare a silver-alumina composite film;

[0023] 6. Configure 10 -6 mol / L rhodamine 6G solution;

[0024] 7. Put the surface-enhanced Raman substrate prepared in steps 1 to 5 into the solution to be tested prepared in...

Embodiment 2

[0029] 1. Clean the silicon wafer substrate or glass substrate sequentially with acetone, alcohol, and deionized water and dry them;

[0030] 2. Fix the pretreated substrate on the sample stage of the electron beam evaporation coating machine;

[0031] 3. At a temperature of 298K, using metallic silver as the target material, pump the chamber of the electron beam evaporation coating machine to 3×10 -5 Pa high vacuum;

[0032] 4. Adjust the incident angle of the electron beam to 83 degrees, and rotate the sample stage at a rate of 10rpm, and grow a 300nm thick silver deposition film obliquely on the substrate of the sample stage;

[0033] 5. By low-temperature atomic layer deposition method, a uniform and dense aluminum oxide film of 1.9nm is deposited on a silver substrate at 60°C to prepare a silver-alumina composite film;

[0034] 6. Configure 10 -6 mol / L rhodamine 6G solution;

[0035] 7. Put the surface-enhanced Raman substrate prepared in steps 1 to 5 into the solutio...

Embodiment 3

[0041] 1. Clean the silicon wafer substrate or glass substrate sequentially with acetone, alcohol, and deionized water and dry them;

[0042] 2. Fix the pretreated substrate on the sample stage of the electron beam evaporation coating machine;

[0043] 3. At a temperature of 298K, using metallic silver as the target material, pump the chamber of the electron beam evaporation coating machine to 3×10 -5 Pa high vacuum;

[0044] 4. Adjust the incident angle of the electron beam to 86 degrees, and make the sample stage static, and grow a 400nm thick silver deposition film obliquely on the base of the sample stage;

[0045] 5. By low-temperature atomic layer deposition method, a uniform and dense aluminum oxide film of 2.6nm is deposited on a silver substrate at 70°C to prepare a silver-alumina composite film;

[0046] 6. Configure 10 -6 mol / L rhodamine 6G solution;

[0047] 7. Put the surface-enhanced Raman substrate prepared in steps 1 to 5 into the solution to be tested prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com