Method for preparing graphene oxide film for sustained release of and graphene oxide film product

A graphene film and graphene technology, which is applied in the field of medicine and chemical industry, can solve the problems of unstable mechanical properties of graphene oxide film, falling off of graphene oxide particles, and speed up the release of loaded drugs, so as to increase drug binding sites, Increase drug load, improve the effect of drug sustained release and controlled release performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 Preparation of graphene oxide film

[0033] Add 10 mg of graphene oxide (purchased from Nanjing Xianfeng Nano Co., Ltd., product number XF002) into 100 mL of deionized water for 2.5 hours to obtain a graphene oxide dispersion; add 1 mL of 10 mg / mL to the graphene oxide dispersion Hyperbranched polyethyleneimine (purchased from SIGMA-ALDRICH company, product number 408727) aqueous solution, vigorously stirred at 180r / min for 30min, sonicated at 200kHz for 15min to obtain a homogeneous mixture, and filtered on CA microfiltration membrane , The suction filtration time is 24h, the graphene oxide film (such as figure 1 ).

Embodiment 2

[0034] Example 2 Preparation of a graphene oxide film containing ciprofloxacin for sustained drug release using dendritic polyethyleneimine as a crosslinking agent

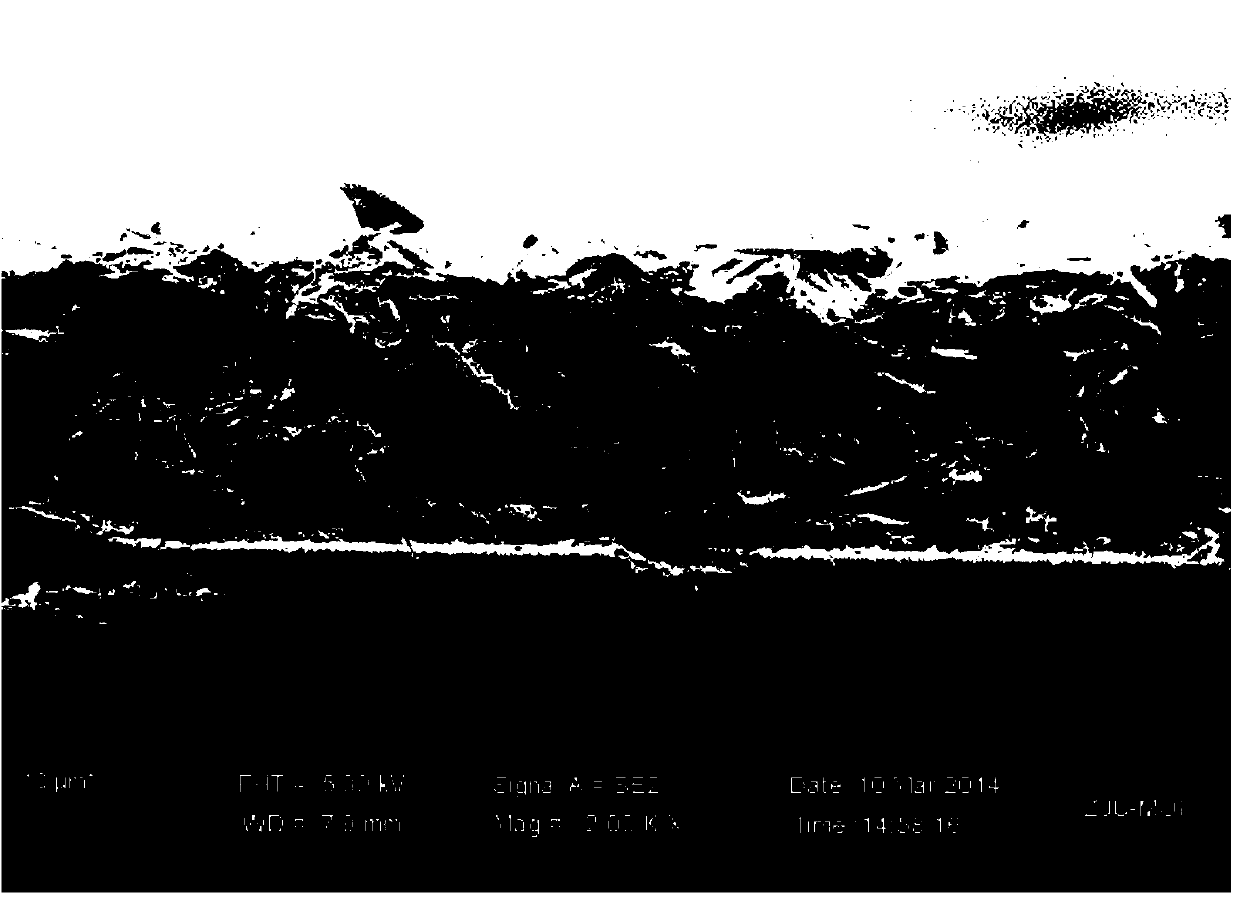

[0035] Add 10 mg of graphene oxide (purchased from Nanjing Xianfeng Nano Co., Ltd., product number XF002) into 100 mL of deionized water and sonicate for 2.5 hours to obtain a graphene oxide dispersion; add 1 mL of 5 mg / mL to the graphene oxide dispersion Dendritic polyethyleneimine (purchased from SIGMA-ALDRICH company, product number 408727) aqueous solution, vigorously stirred at 180r / min for 30 minutes, sonicated at 200kHz for 15 minutes to obtain a uniform mixture; then add 0.1g to the above mixture Ciprofloxacin (purchased from Aladdin Reagent Company, product number C119326), stirred for 30 minutes, sonicated at 200kHz for 15 minutes, and then filtered on a CA microfiltration membrane for 12 hours. The graphene oxide film of floxacin used for drug sustained release (such as figure 2 ).

[0036] The graphene ox...

Embodiment 3

[0038] Example 3 Preparation of a graphene oxide film containing ciprofloxacin for sustained drug release using hyperbranched polyethyleneimine as a crosslinking agent

[0039] Add 10 mg of graphene oxide (purchased from Nanjing Xianfeng Nano Co., Ltd., product number XF002) into 100 mL of deionized water and sonicate for 2.5 hours to obtain a graphene oxide dispersion; add 1 mL of 10 mg / mL to the graphene oxide dispersion Hyperbranched polyethyleneimine (purchased from SIGMA-ALDRICH, product number 408727) aqueous solution, vigorously stirred at 180r / min for 30 minutes, ultrasonicated at 200kHz for 15 minutes, to obtain a homogeneous mixture; then add 0.1g to the above mixture Ciprofloxacin (Aladdin Reagent Company, product catalog number C119326), stirred for 30 minutes, sonicated at 200 kHz for 15 minutes, and then filtered on CA microfiltration membrane for 24 hours to obtain ciprofloxacin Graphene oxide film for sustained drug release.

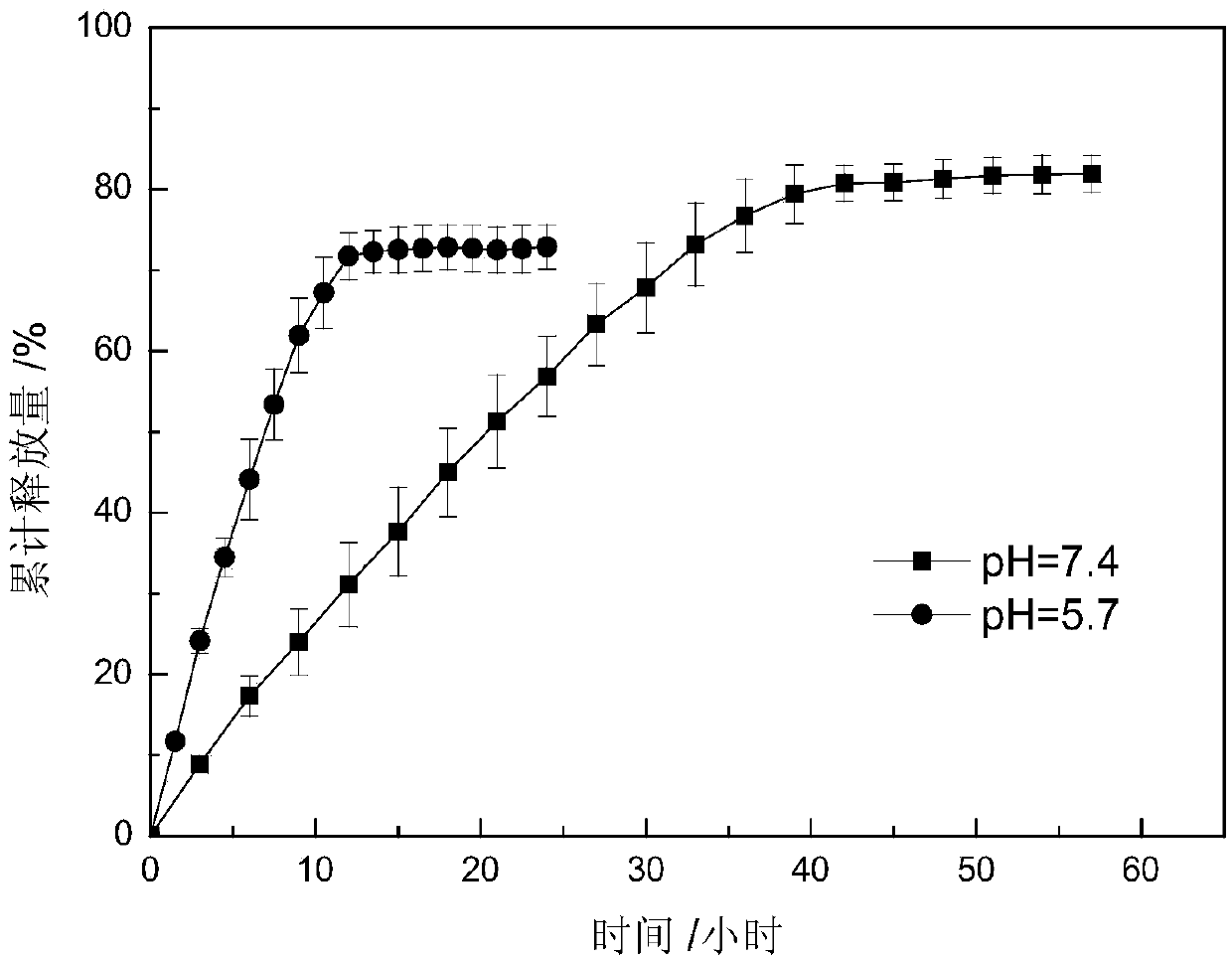

[0040] The graphene oxide film for dru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com