Preparation of Fe3O4-MnO2 composite catalyst and method for removing organic dye in printing and dyeing wastewater by using Fe3O4-MnO2 composite catalyst

A technology for composite catalysts and printing and dyeing wastewater, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. Low degradation rate, difficult to maintain catalytic effect and stability, etc., to achieve the effect of short time, low processing cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

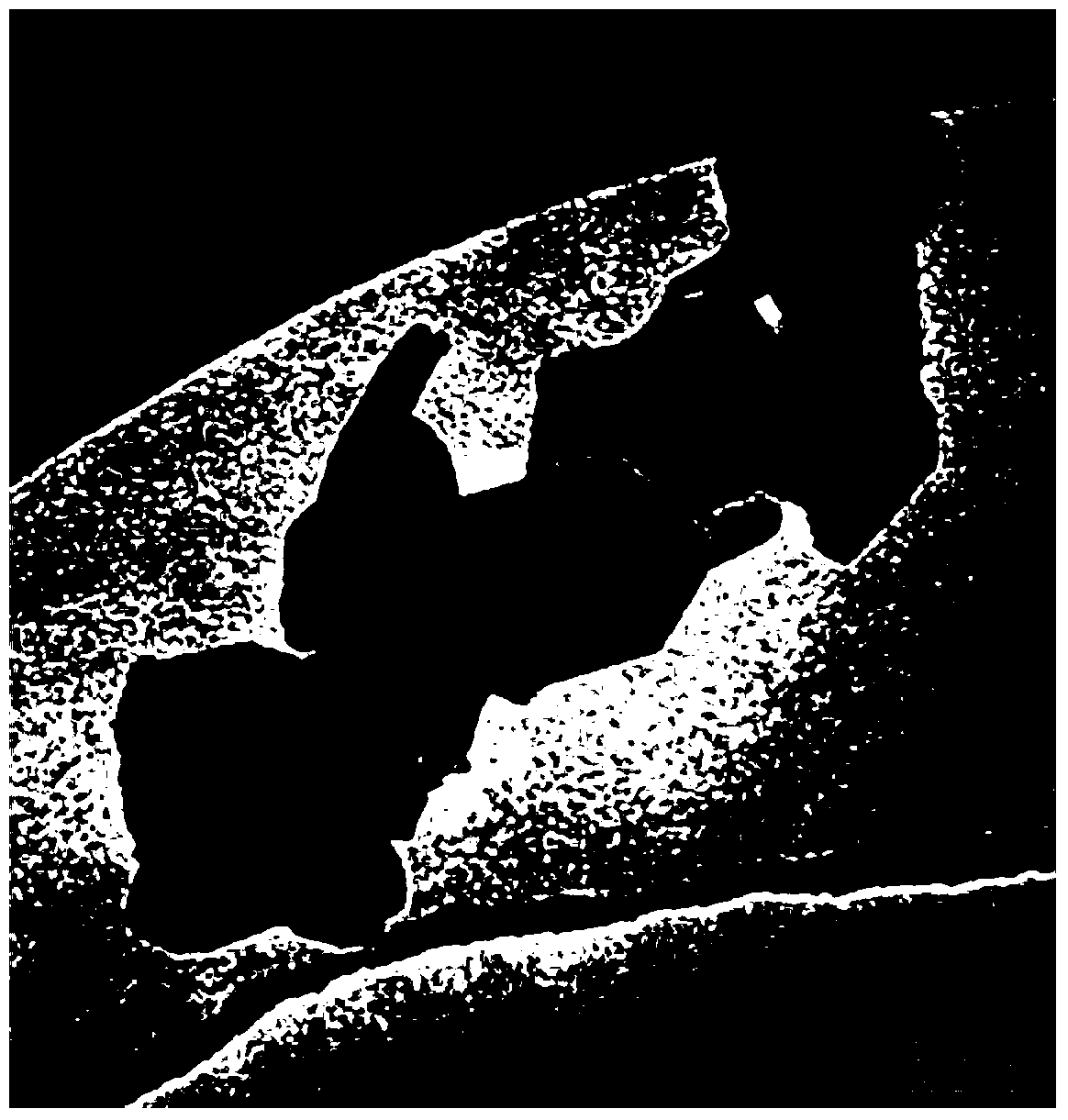

[0013] Specific implementation mode one: this implementation mode is Fe 3 o 4 -MnO 2 The preparation method of composite catalyst is specifically completed in the following steps: FeSO 4 ·7H 2 O and polyvinylpyrrolidone were dissolved in water, and the obtained mixture was added to deionized water at a temperature of 90°C, and NaOH was added, stirred and reacted at a temperature of 90°C for 2 minutes, and a green-brown precipitate was formed, which was statically settled at a temperature of 90°C for 2 minutes , then add KMnO 4 , stirred and reacted at a temperature of 90°C for 1 min, and then separated and obtained a solid precipitate after static precipitation at a temperature of 90°C for 4 to 6 hours. The solid precipitate was washed three times with deionized water, then washed three times with absolute ethanol, and dried Fe 3 o 4 -MnO 2 Composite catalyst.

[0014] The FeSO described in this embodiment 4 ·7H 2 The mass ratio of the amount of O to polyvinylpyrroli...

specific Embodiment approach 2

[0023] Specific embodiment two: the difference between this embodiment and specific embodiment one is: adding KMnO 4 , the reaction was stirred at a temperature of 90° C. for 1 min, and then a solid precipitate was isolated after static precipitation at a temperature of 90° C. for 4 h. Others are the same as the first embodiment.

specific Embodiment approach 3

[0024] Specific implementation mode three: this embodiment mode utilizes Fe 3 o 4 -MnO 2 The method for removing organic dyes in printing and dyeing wastewater with a composite catalyst is specifically completed as follows: firstly adjust the pH value of the printing and dyeing wastewater containing organic dyes to 6.5 to 7.5, and then add potassium hydrogen persulfate and Fe 3 o 4 -MnO 2 Composite catalyst, stirring and reacting at room temperature for 15min to 35min, the utilization of Fe 3 o 4 -MnO 2 Composite catalyst removes organic dyestuff in printing and dyeing wastewater; Described potassium persulfate and Fe 3 o 4 -MnO 2 The mass ratio of the composite catalyst is (2~4):1; the Fe 3 o 4 -MnO 2 The mass ratio of the composite catalyst to the printing and dyeing wastewater containing the organic dye is (0.1-0.3) g:1L.

[0025]Advanced oxidation technology can mineralize and degrade refractory organic matter under normal temperature and pressure, which is a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com