A biobr-based heterojunction with visible light catalytic activity and its preparation method

A catalytic activity, visible light technology, applied in the direction of illumination water/sewage treatment, etc., can solve the problems to be further improved, and achieve the effect of electron transfer and catalytic activity improvement, low cost, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Pure BiOBr was prepared as follows:

[0023] ①Mix 0.01mol of bismuth nitrate with 0.008mol of 2-bromoethylamine hydrobromide, 0.005mol of tetramethylammonium bromide and 0.003mol of urea, and heat to melt to form an ionic liquid;

[0024] ②Heating the ionic liquid described in step ① on an electric furnace until the ionic liquid burns, and the combustion produces a large amount of smoke and emits a large amount of heat;

[0025] ③Collect the solid produced after complete combustion in step ②, cool and grind to obtain a powder, which is designated as sample A.

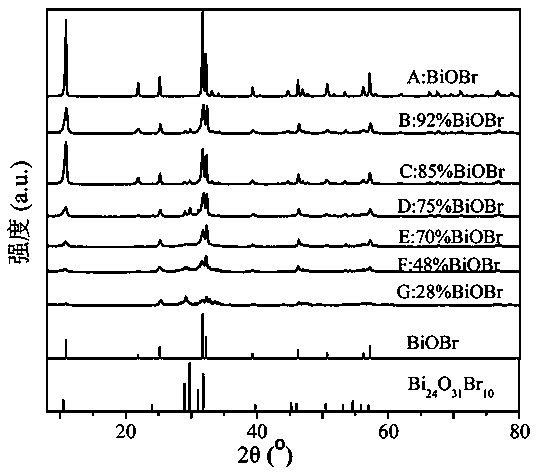

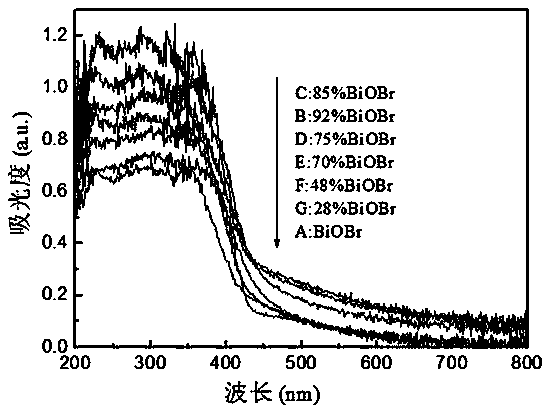

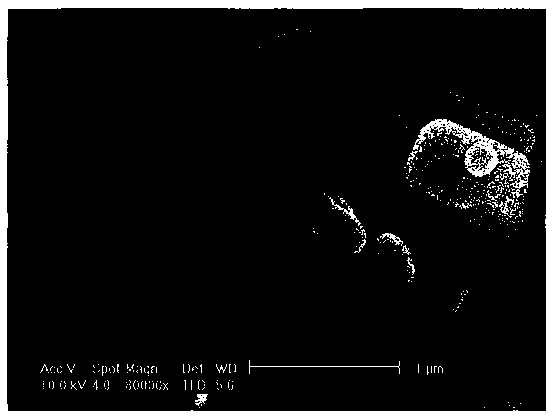

[0026] Sample A was tested by XRD, UV-VisDRS and SEM respectively, and the test patterns were as follows Figure 1 to Figure 3 shown. figure 1 XRD patterns show that the powder is pure BiOBr. From figure 2 It can be seen from the figure that the pure BiOBr prepared in this example has absorption in the visible light region, using α(hν)=a(hν-E g ) 2 The formula calculates that its forbidden band width is ab...

Embodiment 2

[0029] Follow the steps below to prepare BiOBr / Bi 24 o 31 Br 10 Heterojunction:

[0030] ① Mix 0.01mol bismuth nitrate with 0.0060mol 2-bromoethylamine hydrobromide, 0.001mol tetraethylammonium bromide and 0.005mol urea and heat until melted to form an ionic liquid;

[0031] ②Heating the ionic liquid described in step ① on an electric furnace until the ionic liquid burns, and the combustion produces a large amount of smoke and emits a large amount of heat;

[0032] ③Collect the solid produced after complete combustion in step ②, cool and grind to obtain a powder, which is designated as sample B.

[0033] Carry out XRD and UV-VisDRS test to sample B, its pattern see respectively figure 1 and figure 2 ,use figure 1 Its peak intensity and BiOBr and Bi 24 o 31 Br 10 The RIR value can be calculated to get BiOBr and Bi 24 o 31 Br 10 The mass fractions were 91.8% and 8.2%, respectively. Depend on figure 2 Using α(hν)=a(hν-E g ) 2 The formula calculates that its forb...

Embodiment 3

[0036] Follow the steps below to prepare BiOBr / Bi 24 o 31 Br 10 Heterojunction:

[0037] ① Mix and heat 0.01mol bismuth nitrate, 0.0060mol 2-bromoethylamine hydrobromide and 0.008mol urea until melted to form an ionic liquid;

[0038] ②Heating the ionic liquid described in step ① on an electric furnace until the ionic liquid burns, and the combustion produces a large amount of smoke and emits a large amount of heat;

[0039] ③Collect the solid produced after complete combustion in step ②, cool and grind to obtain a powder, which is designated as sample C.

[0040] Carry out XRD and UV-VisDRS test to sample C, its pattern see respectively figure 1 and figure 2 ,use figure 1 Its peak intensity and BiOBr and Bi 24 o 31 Br 10 The RIR value can be calculated to get BiOBr and Bi 24 o 31 Br 10 The mass fractions were 85.2% and 14.8%, respectively. Depend on figure 2 Using α(hν)=a(hν-E g ) 2 The formula calculates that its forbidden band width is about 2.53eV.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com