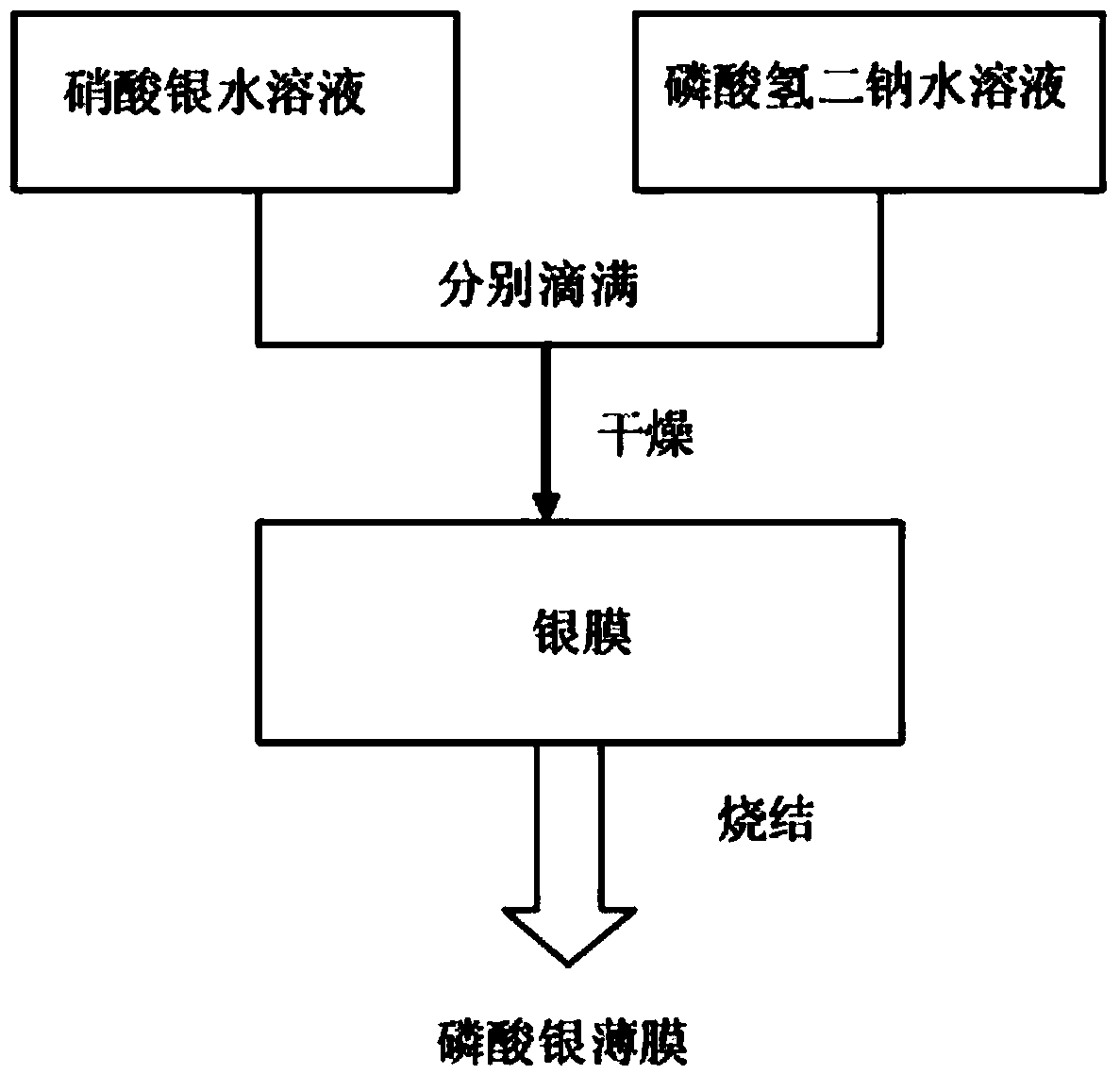

Preparation method of silver phosphate film

A silver phosphate film, silver phosphate technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc. Hydrogen and other problems, to achieve the effect of low cost, easy operation, and easy control of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

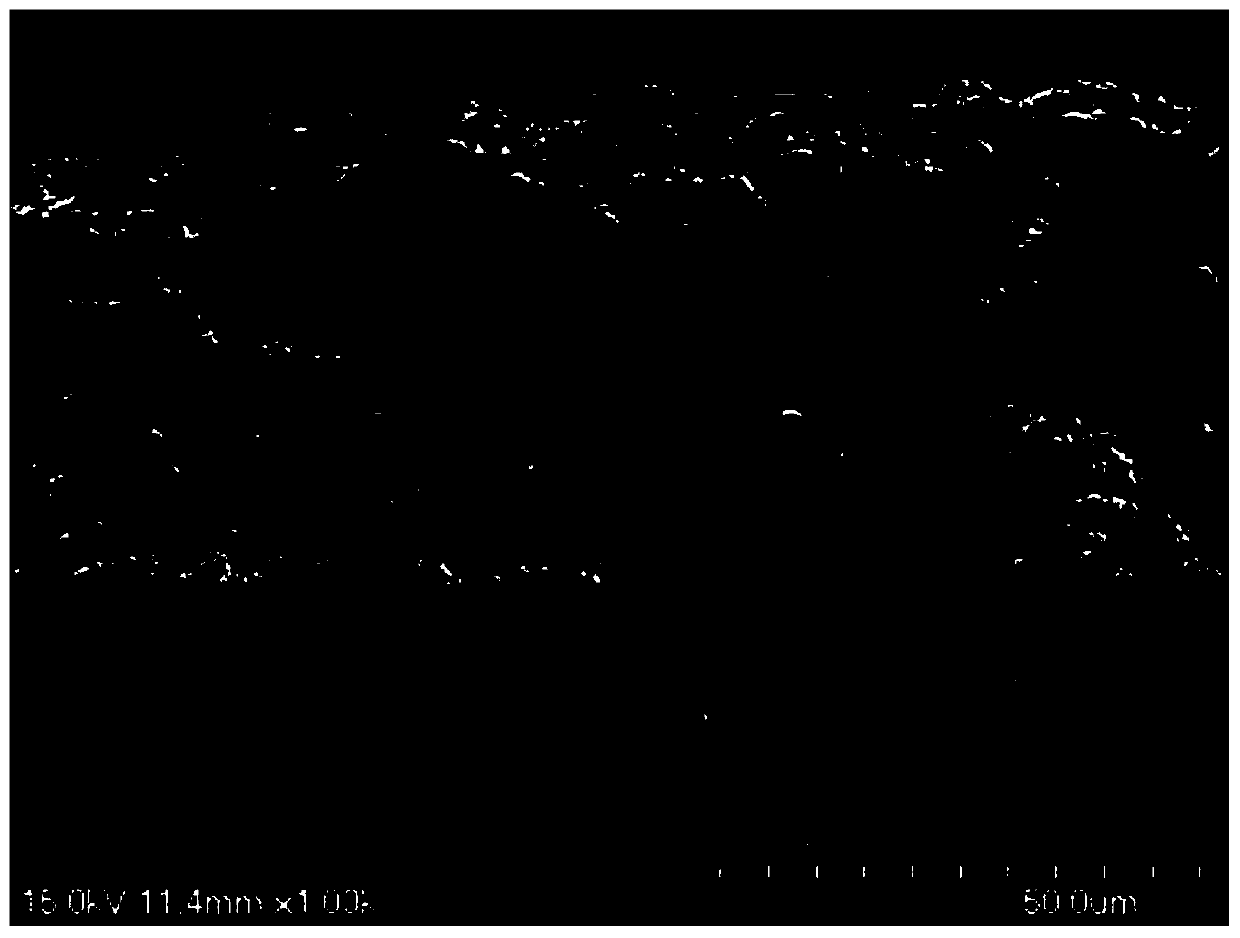

[0020] A silver film was deposited as a seed layer by magnetron sputtering on a glass substrate, and silver nitrate AgNO with a mass percentage concentration of 0.17% was dropped on the silver film. 3 Aqueous solution, spin-coat, dry. Then drip full mass percentage concentration is 0.14% disodium hydrogen phosphate Na 2 HPO 4 aqueous solution, and then spin-coated and dried in the same manner. Repeat the above steps 5 times to obtain silver phosphate Ag 3 PO 4 Prefabricated film. Finally, it was sintered at 400°C for 1.5h to obtain silver phosphate Ag with good binding force. 3 PO 4 film.

Embodiment 2

[0022] in TiO 2 On the glass substrate, a 100nm thick silver film is formed as a seed layer by thermal evaporation, and silver nitrate AgNO with a mass percentage concentration of 0.34% is dripped on the silver film. 3 Aqueous solution, spin-coat, dry. It is 0.28% disodium hydrogen phosphate Na to drip full mass percent concentration on it again 2 HPO 4 aqueous solution, dried at 60°C for 10 minutes, and repeated the above steps 3 times to obtain silver phosphate Ag 3 PO 4 Prefabricated film. Finally, sinter at 300°C for 1 hour to obtain silver phosphate Ag with good binding force 3 PO 4 film.

Embodiment 3

[0024] On a transparent conductive glass substrate, a 50nm silver film is formed as a seed layer by electrodeposition, and the silver film is dripped with a mass percentage concentration of 0.017% silver nitrate AgNO 3 Aqueous solution, directly dried in an oven at 60°C. It is 0.014% disodium hydrogen phosphate Na on it dripping full mass percent concentration again 2 HPO 4 The aqueous solution is directly placed in an oven at 60°C to dry to obtain a silver phosphate film. Finally, sinter at 550°C for 2 hours to obtain silver phosphate Ag with good binding force. 3 PO 4 film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com