High-strength poplar laminated veneer lumber and manufacturing method thereof

A technology of poplar veneer and manufacturing method, which is applied in the direction of wood layered products, bonding of wooden veneers, manufacturing tools, etc., to achieve the effects of improving bonding strength, improving mechanical properties, and shortening hot-pressing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

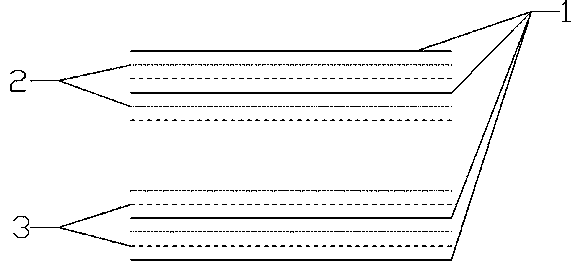

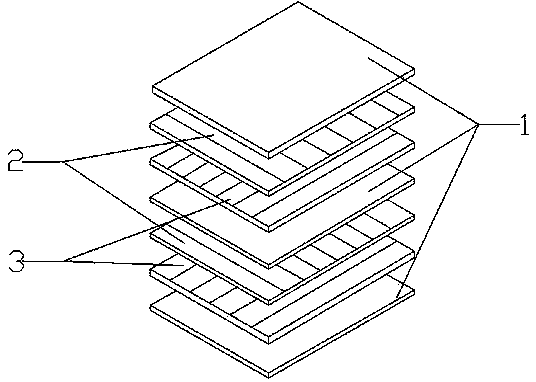

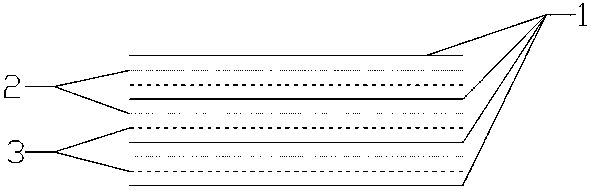

[0031] A high-strength poplar veneer laminated lumber is reinforced by adding a layer of glass fiber cloth and a layer of carbon fiber cloth between any two layers of poplar veneer. Its structure is composed of poplar veneer 1 and glass fiber cloth 2 and carbon fiber cloth 3 are sequentially laminated and glued together; the thickness of the poplar veneer is 3.2 mm, the thickness of the glass fiber cloth is 0.1 mm, and the thickness of the carbon fiber cloth is 0.111 mm. A water-soluble phenolic resin adhesive is bonded between the poplar veneer layer and the glass fiber cloth and the carbon fiber cloth.

Embodiment 2

[0033] A high-strength poplar veneer laminated lumber is reinforced by adding a layer of glass fiber cloth and a layer of carbon fiber cloth between any two layers of poplar veneer. Its structure is composed of poplar veneer 1 and glass fiber cloth 2 and carbon fiber cloth 3 are sequentially laminated and glued; the thickness of the poplar veneer is 2 mm, the thickness of the glass fiber cloth is 0.1 mm, and the thickness of the carbon fiber cloth is 0.111 mm. A water-soluble phenolic resin adhesive is bonded between the poplar veneer layer and the glass fiber cloth and the carbon fiber cloth.

Embodiment 3

[0035] A method for manufacturing high-strength poplar laminated veneer lumber, comprising:

[0036] 1. Raw material preparation: Use rotary-cut poplar veneer with a moisture content of 6% to 8%, with a thickness of 3.2mm, and E-GLASS alkali-free glass fiber cloth produced by Changzhou Hualike New Material Co., Ltd., with a thickness of 0.1mm. mm, choose PAN-based carbon fiber cloth produced by Changzhou Hualike New Material Co., Ltd., with a thickness of 0.111mm;

[0037] 2. Fiber cloth impregnation: impregnate the glass fiber cloth and carbon fiber cloth in the water-soluble phenolic resin adhesive, take it out after about 15 minutes and dry it or dry it until it is not sticky;

[0038] 3. Veneer glue coating: use water-soluble phenolic resin adhesive to glue the poplar veneer, and the amount of glue on one side is 120-160g / m 2 ;

[0039] 4. Blank assembly: The glued poplar veneer is assembled along the grain, and a layer of glass fiber cloth and a layer of carbon fiber cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com