Low expansion mat glaze and cordierite barbecue plate coated with glaze

A low-expansion, matte glaze technology, applied in the field of ceramic glazes, can solve difficulties and other problems, and achieve the effect of fine and smooth glaze surface, small thermal expansion coefficient and good thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] (1) Preparation of bottom glaze slurry

[0040] 1) Weigh raw materials for bottom glaze: 50-75 parts of spodumene, 0-10 parts of quartz, 5-10 parts of dolomite, 5-15 parts of talc, 0-3 parts of lithium carbonate, 3-7 parts of kaolin, barium carbonate 0-3 parts, mix well;

[0041] 2) Add sodium carboxymethyl cellulose, sodium tripolyphosphate and water to the above mixture, the mass of which is respectively 0.2-0.4%, 0.2-0.5% and 50-70% of the total mass of the bottom glaze raw materials, and ball mill to form a glaze slurry , control the fineness of the glaze slurry to be 250 mesh sieve ≤ 1.5%, and obtain the bottom glaze slurry;

[0042] (2) Preparation of surface glaze slurry

[0043] 1) Weigh the surface glaze raw materials: 50-75 parts of spodumene, 5-15 parts of quartz, 0-8 parts of dolomite, 3-10 parts of kaolin, 0-5 parts of zinc oxide, and mix well;

[0044] 2) Add sodium carboxymethyl cellulose, sodium tripolyphosphate and water to the above mixture, the mas...

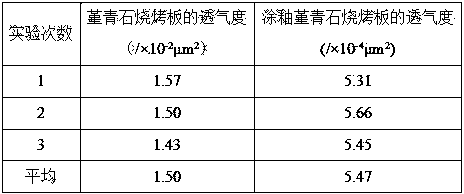

Embodiment 1

[0056] (1) Preparation of bottom glaze slurry

[0057] 1) Weigh the bottom glaze raw materials: 50 parts of spodumene, 10 parts of quartz, 10 parts of dolomite, 11 parts of talc, 2 parts of lithium carbonate, 6 parts of kaolin, 3 parts of barium carbonate, and mix well;

[0058] 2) Add sodium carboxymethyl cellulose, sodium tripolyphosphate and water to the above mixture, the mass of which is respectively 0.25%, 0.3% and 50% of the total mass of the bottom glaze raw materials, and ball mill it into a glaze slurry to control the fineness of the glaze slurry It is 250 mesh sieve remaining 1%, obtains bottom glaze slurry, and its specific gravity is 1.65g / cm 3 ;

[0059] (2) Preparation of surface glaze slurry

[0060] 1) Weigh the surface glaze raw materials: 58 parts of spodumene, 13 parts of quartz, 6 parts of dolomite, 10 parts of kaolin, 2 parts of zinc oxide, and mix well;

[0061] 2) Add sodium carboxymethyl cellulose, sodium tripolyphosphate and water to the above mixt...

Embodiment 2

[0069] (1) Preparation of bottom glaze slurry

[0070] 1) Weigh the bottom glaze raw materials: 60 parts of spodumene, 6 parts of quartz, 9 parts of dolomite, 11 parts of talc, 2.5 parts of lithium carbonate, 4 parts of kaolin, 2.5 parts of barium carbonate, and mix well;

[0071] 2) Add sodium carboxymethyl cellulose, sodium tripolyphosphate and water to the above mixture, the mass of which is respectively 0.25%, 0.3% and 50% of the total mass of the bottom glaze raw materials, and ball mill it into a glaze slurry to control the fineness of the glaze slurry Be 250 mesh sieve remaining 0.5%, obtain bottom glaze slurry;

[0072] (2) Preparation of surface glaze slurry

[0073] 1) Weigh the surface glaze raw materials: 60 parts of spodumene, 13 parts of quartz, 5 parts of dolomite, 10 parts of kaolin, 2 parts of zinc oxide, mix well;

[0074] 2) Add sodium carboxymethyl cellulose, sodium tripolyphosphate and water to the above mixture, the mass of which is respectively 0.25%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average coefficient of thermal expansion | aaaaa | aaaaa |

| Average coefficient of thermal expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com