A method for separating ornithine and forming ornithine hydrochloride from ornithine conversion liquid prepared by enzyme biotechnology

A technology of ornithine hydrochloride and biotechnology, which is applied in the field of separating ornithine and forming ornithine hydrochloride, which can solve the problems of increasing production costs due to production requirements, increasing production costs of enterprises, and reducing the technical threshold Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

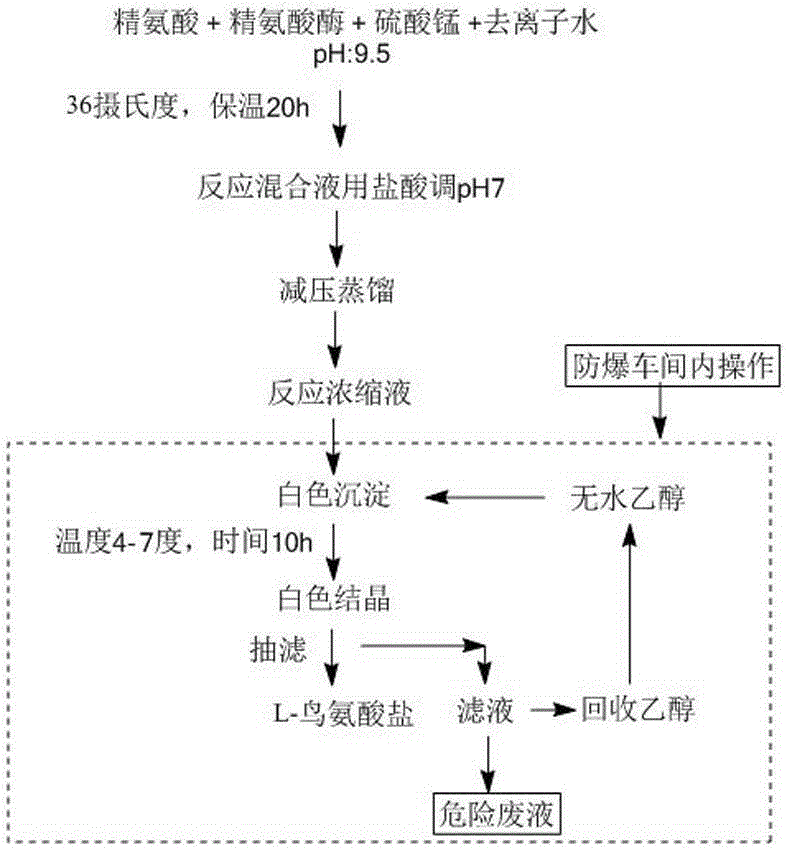

Image

Examples

Embodiment 1

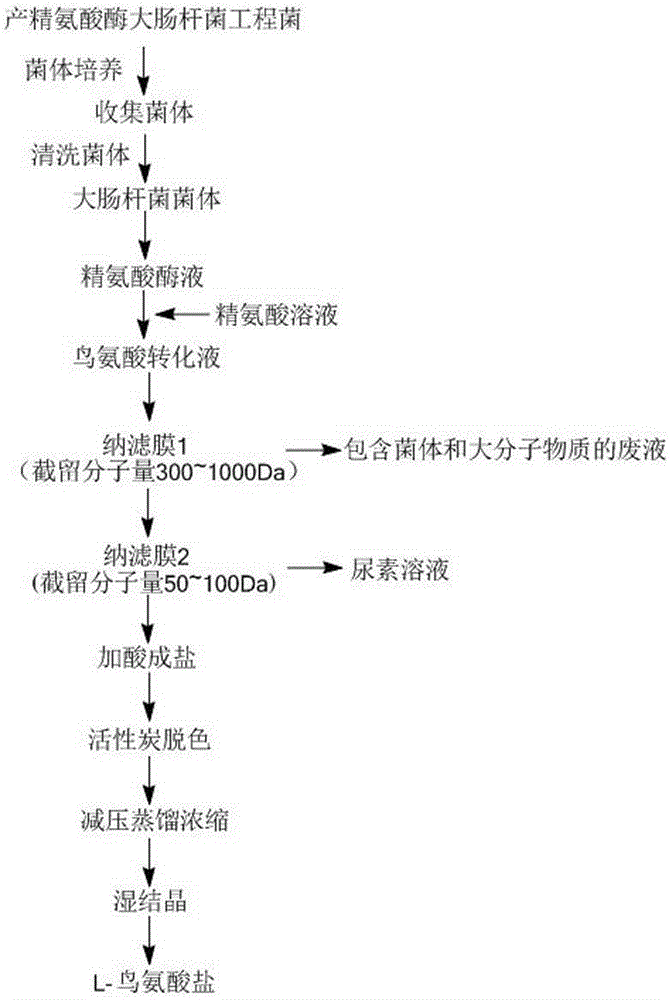

[0025] The method steps of separating ornithine and forming ornithine hydrochloride from the ornithine conversion liquid prepared by enzyme biotechnology of the present invention are as follows:

[0026] 1. Preparation of arginase solution:

[0027] (1) Seed liquid culture:

[0028] Inoculate arginase-producing Escherichia coli engineering bacteria E.coliBL21 into 500mL LB liquid medium, and cultivate it to OD at 37°C and 200rpm 600 The value is 2.71, spare.

[0029] (2) Fermentation culture:

[0030] The seed solution was added in a ratio of 1:100 (v / v), that is, 50 L of LB liquid medium was added to a 70 L fermenter, and then 0.5 L of seed solution was added for fermentation. The culture temperature is 37° C., the rotation speed is 300 rpm, and the initial pH is 7.2. Sampling every 1 hour, when OD 600 When the value is about 4.0, the tank is lowered and the bacteria are collected.

[0031] (3) The fermented liquid in the lower tank first passes through a 200-mesh dryin...

Embodiment 2

[0051] The difference between this embodiment and embodiment 1 is:

[0052] Step 3: Separating ornithine in the ornithine conversion solution and forming a salt

[0053] Take 100L of the conversion solution and separate it with nanofiltration membrane 1, the molecular weight cut off of the nanofiltration membrane 1 is 300Da. Thereby obtain filtrate 1; Then filtrate 1 is filtered with nanofiltration membrane 2, and the molecular weight cut-off of this nanofiltration membrane 2 is 100Da, also obtained urea solution simultaneously, and filtrate 2 is adjusted pH5.0-6.0 with hydrochloric acid, forms ornithine For the hydrochloride solution, use 767 activated carbon to decolorize and absorb the trace impurities remaining in ornithine hydrochloride. The decolorization temperature is 80°C, and the stirring is continued for 30 minutes. The amount of activated carbon added is 20% of the solid content of the ornithine hydrochloride solution. , decarburization to obtain filtrate 3; above...

Embodiment 3

[0058] The difference between this embodiment and embodiment 1 is:

[0059] Step 3: Separating ornithine in the ornithine conversion solution and forming a salt

[0060] Take 100L of the conversion solution and separate it with nanofiltration membrane 1, the molecular weight cut off of the nanofiltration membrane 1 is 300Da. Thereby obtain filtrate 1; Then filtrate 1 is filtered with nanofiltration membrane 2, the molecular weight cut-off of this nanofiltration membrane 2 is 60Da, obtains filtrate 2, also obtained urea solution simultaneously, filtrate 2 is regulated PH5.0-6.0 with hydrochloric acid, Form ornithine hydrochloride solution, use 767 type activated carbon to decolorize and absorb trace impurities remaining in ornithine hydrochloride, decolorize temperature 80°C, keep stirring for 30min, the amount of activated carbon added is the solid content of ornithine hydrochloride solution 20% of content, decarburization obtains filtrate 3; above-mentioned filtrate 3 is sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com