Method for detecting vinyl acetate in hot melt adhesive

A technology of vinyl acetate and detection method, applied in the field of analytical chemistry, to achieve the effect of simple sample pretreatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

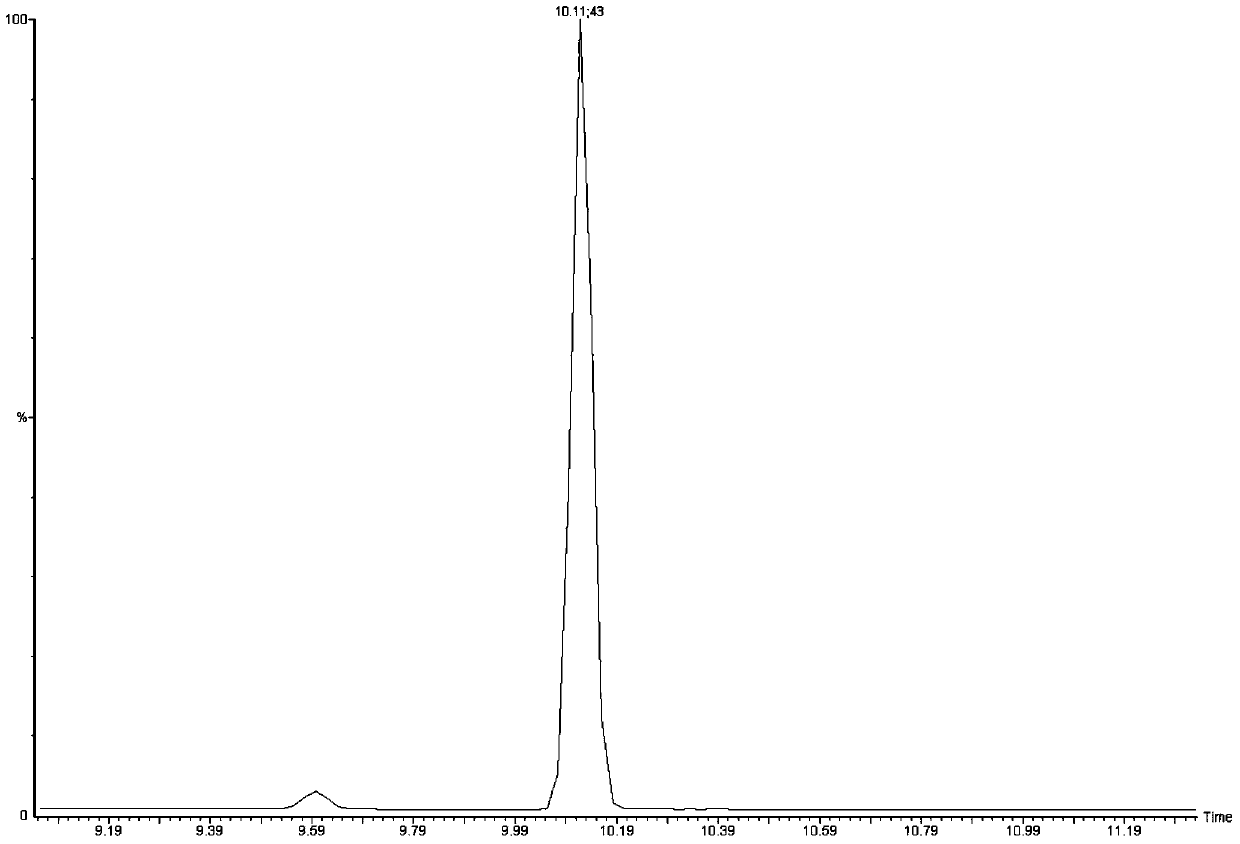

Image

Examples

Embodiment 1

[0018] Weigh 0.2 g of the hot melt adhesive sample into the headspace vial, add 1 mL of triacetin as a matrix corrector, quickly seal it, analyze it by headspace-gas chromatography-mass spectrometry, and quantify it with the external standard method.

[0019] The headspace vial injection conditions are as follows:

[0020] The equilibrium temperature of the hot melt adhesive sample is 130 °C, the ring temperature is 150 °C, the transfer line temperature is 170 °C, the hot melt adhesive sample equilibration time is 30 min, the pressurization time is 0.2 min, the inflation time is 0.2 min, and the injection time is 1.0 min. min.

[0021] The gas chromatography conditions are as follows:

[0022] The chromatographic column is a VOC-specific capillary column or equivalent column, with a length of 60 m×inner diameter of 0.32 mm×film thickness of 1.8 μm; the carrier gas is helium (He); the temperature of the injection port is 170 °C; constant flow mode, column flow rate 1.0 mL / mi...

Embodiment 2

[0027] Weigh 0.3 g of the hot melt adhesive sample into the headspace vial, add 1 mL of triacetin as a matrix corrector, quickly seal it, analyze it by headspace-gas chromatography-mass spectrometry, and quantify it by the external standard method. The headspace vial injection conditions are as follows:

[0028] The equilibrium temperature of the hot melt adhesive sample is 110 °C, the ring temperature is 160 °C, the transfer line temperature is 165 °C, the hot melt adhesive sample equilibration time is 40 min, the pressurization time is 0.3 min, the inflation time is 0.3 min, and the injection time is 1.5 min. min.

[0029] The gas chromatography conditions are as follows:

[0030] The chromatographic column is a VOC-specific capillary column or equivalent column, with a length of 60 m×inner diameter of 0.32 mm×film thickness of 1.8 μm; the carrier gas is helium (He); the temperature of the injection port is 175°C; constant flow mode, column flow rate 1.5 mL / min, with a sp...

Embodiment 3

[0035] Weigh 0.4 g of hot melt adhesive sample into the headspace vial, add 2 mL of triacetin triacetate as a matrix corrector, quickly seal it, analyze it by headspace-gas chromatography-mass spectrometry, and quantify it with the external standard method. The headspace vial injection conditions are as follows:

[0036] The equilibrium temperature of the hot melt adhesive sample is 120 °C, the ring temperature is 145 °C, the transfer line temperature is 160 °C, the hot melt adhesive sample equilibration time is 50 min, the pressurization time is 0.4 min, the inflation time is 0.4 min, and the injection time is 2.0 min. min.

[0037] The gas chromatography conditions are as follows:

[0038] The chromatographic column is a VOC-specific capillary column or equivalent column, with a length of 60 m×inner diameter of 0.32 mm×film thickness of 1.8 μm; the carrier gas is helium (He); the temperature of the injection port is 180 ℃; the constant flow mode, the column flow rate is 2.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com