Magnetoelectric surface-acoustic-wave magnetic-field sensor and manufacturing method thereof

A magnetic field sensor and surface acoustic wave technology, which is applied to the size/direction of the magnetic field and the use of electromagnetic devices for magnetic field measurement, etc., can solve the problems of insufficient size, increased charge noise, unstable interface bonding force, etc., and achieves a simple preparation method. , Easy to operate, strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

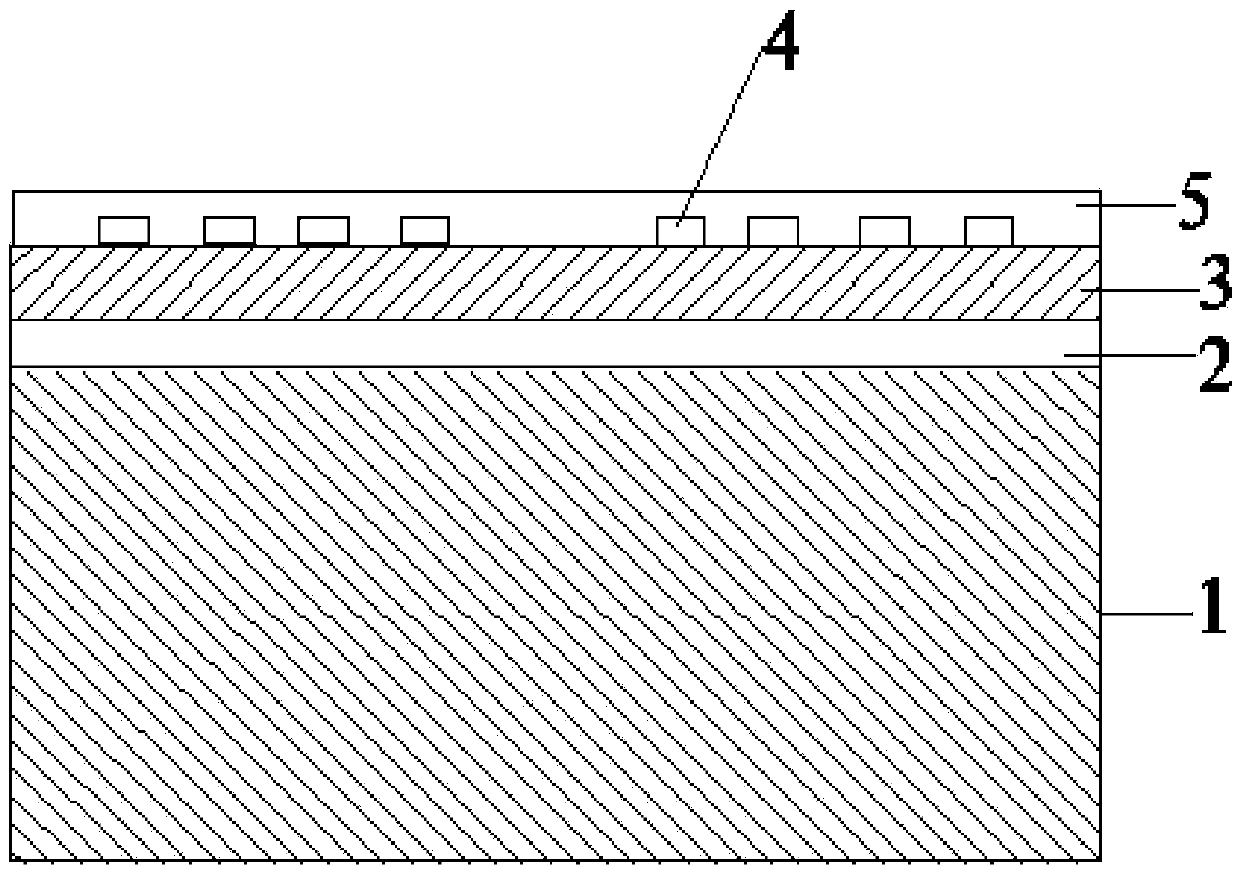

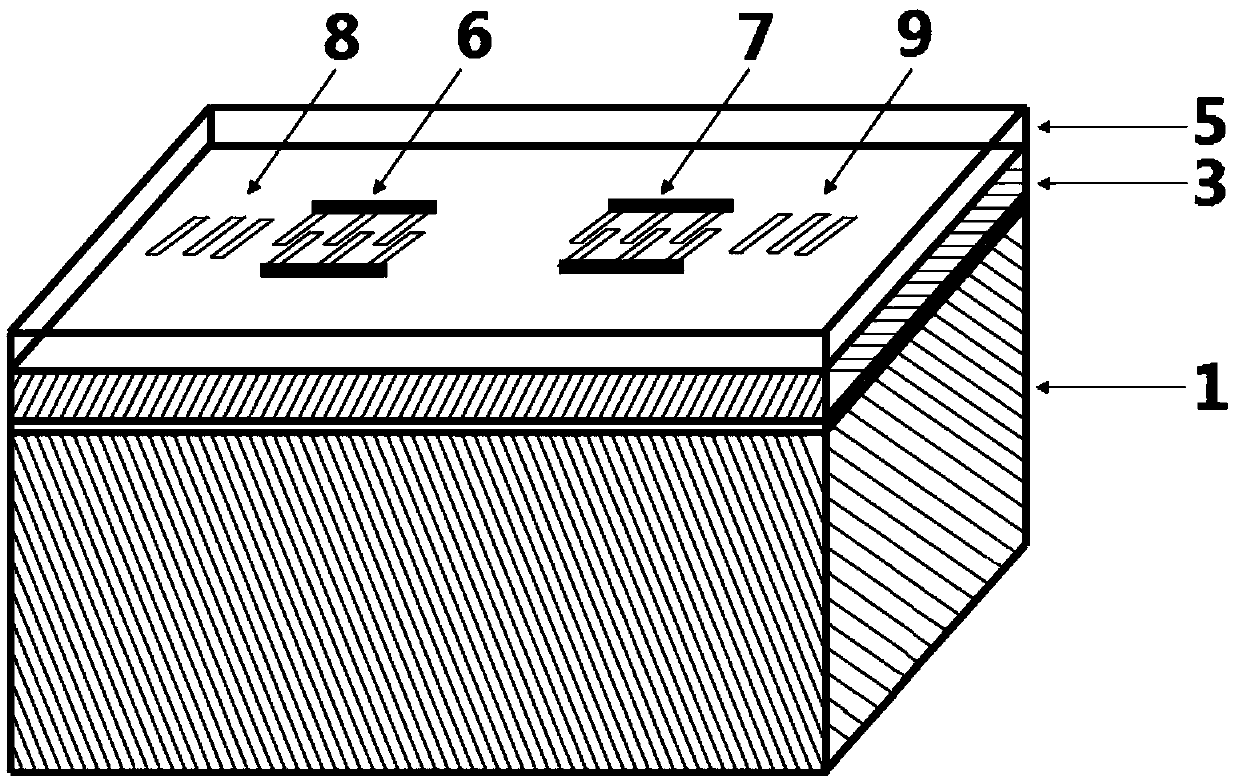

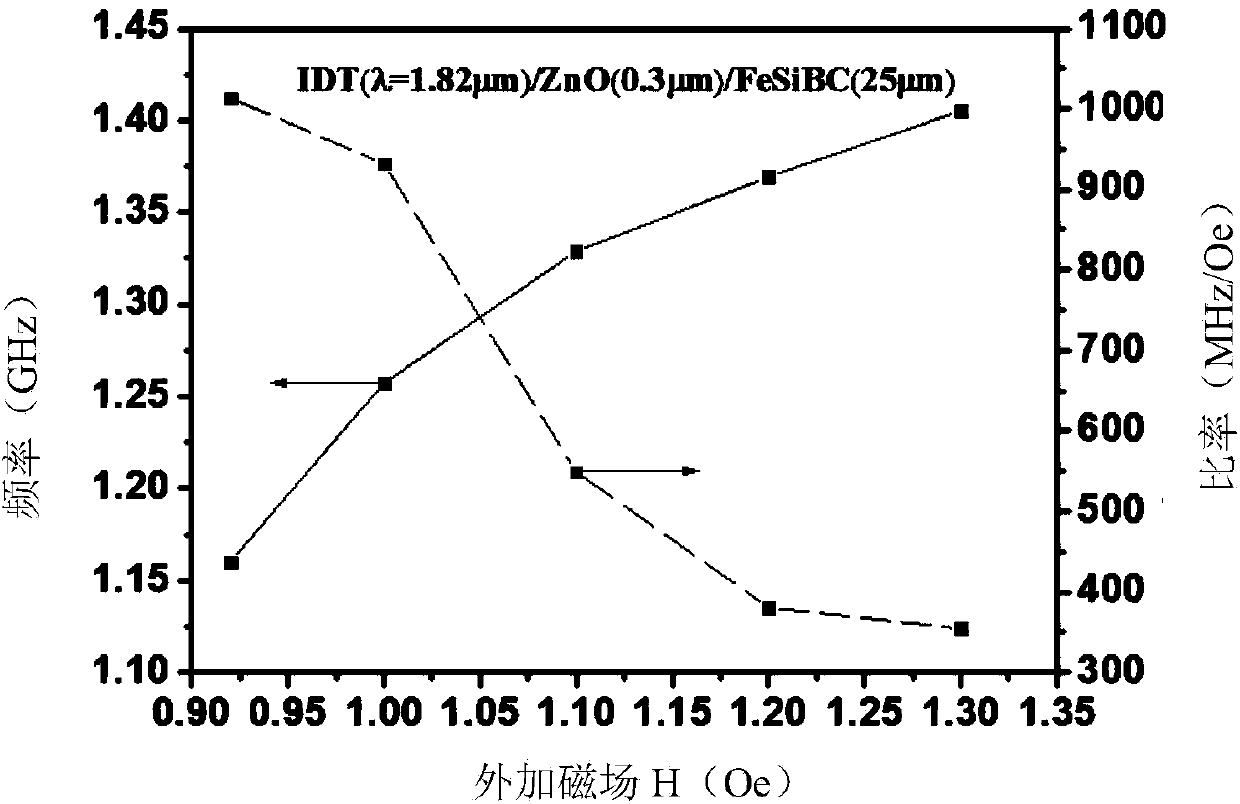

[0043] In this example, the method for preparing a magnetoelectric acoustic surface wave magnetic field sensor comprises the following steps:

[0044] 1) Fe with a thickness of 25 microns 81 Si 13.5 B 3.5 The magnetostrictive amorphous strip of C is used as the magnetostrictive substrate, its thickness is greater than 2 times the wavelength of the surface acoustic wave, the magnetostrictive coefficient is 35ppm, the coercive force along the easy magnetization direction is 80 %; Then use a polishing machine to polish the surface of the magnetostrictive strip, and the polishing solution uses 50nm SiO 2 Suspend the polishing solution, then wash the magnetostrictive strip with absolute ethanol in a high-power ultrasonic machine for 10 minutes, and finally wash it with N 2 Blow dry the magnetostrictive amorphous ribbon.

[0045] 2) in Fe 81 Si 13.5 B 3.5 A 20 nm titanium buffer layer was deposited on C by sputtering.

[0046] 3) A c-axis oriented ZnO piezoelectric thin film...

Embodiment 2

[0050] In this example, the method for preparing a magnetoelectric acoustic surface wave magnetic field sensor comprises the following steps:

[0051] 1) Fe with a thickness of 20 microns 80 Si 9 B 11 The magnetostrictive amorphous strip is used as the magnetostrictive substrate, its thickness is greater than 2 times the wavelength of the surface acoustic wave, the magnetostriction coefficient is 30ppm, the coercive force along the easy magnetization direction is 2Oe, and the remanence ratio is >79.8%; Then use a polishing machine to polish the surface of the magnetostrictive strip, and the polishing solution uses 50nm SiO 2 Suspend the polishing solution, then wash the magnetostrictive strip with absolute ethanol in a high-power ultrasonic machine for 10 minutes, and finally wash it with N 2 Blow dry the magnetostrictive amorphous ribbon.

[0052] 2) in Fe 80 Si 9 B 11 A 20nm titanium buffer layer was sputter deposited on top.

[0053] 3) PZT (Pb 1.1 (Zr 0.58 Ti 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Magnetostriction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com