High-nonlinearity dispersion flattened photonic crystal fiber with pentagonal core

A photonic crystal fiber, high nonlinear technology, applied in the direction of cladding fiber, optical waveguide light guide, etc., can solve the problems that cannot meet the application requirements well, the performance of the flat dispersion photonic crystal fiber is not outstanding, and achieve the improvement of air holes Collapse problem, improvement of dispersion and nonlinear characteristics, effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

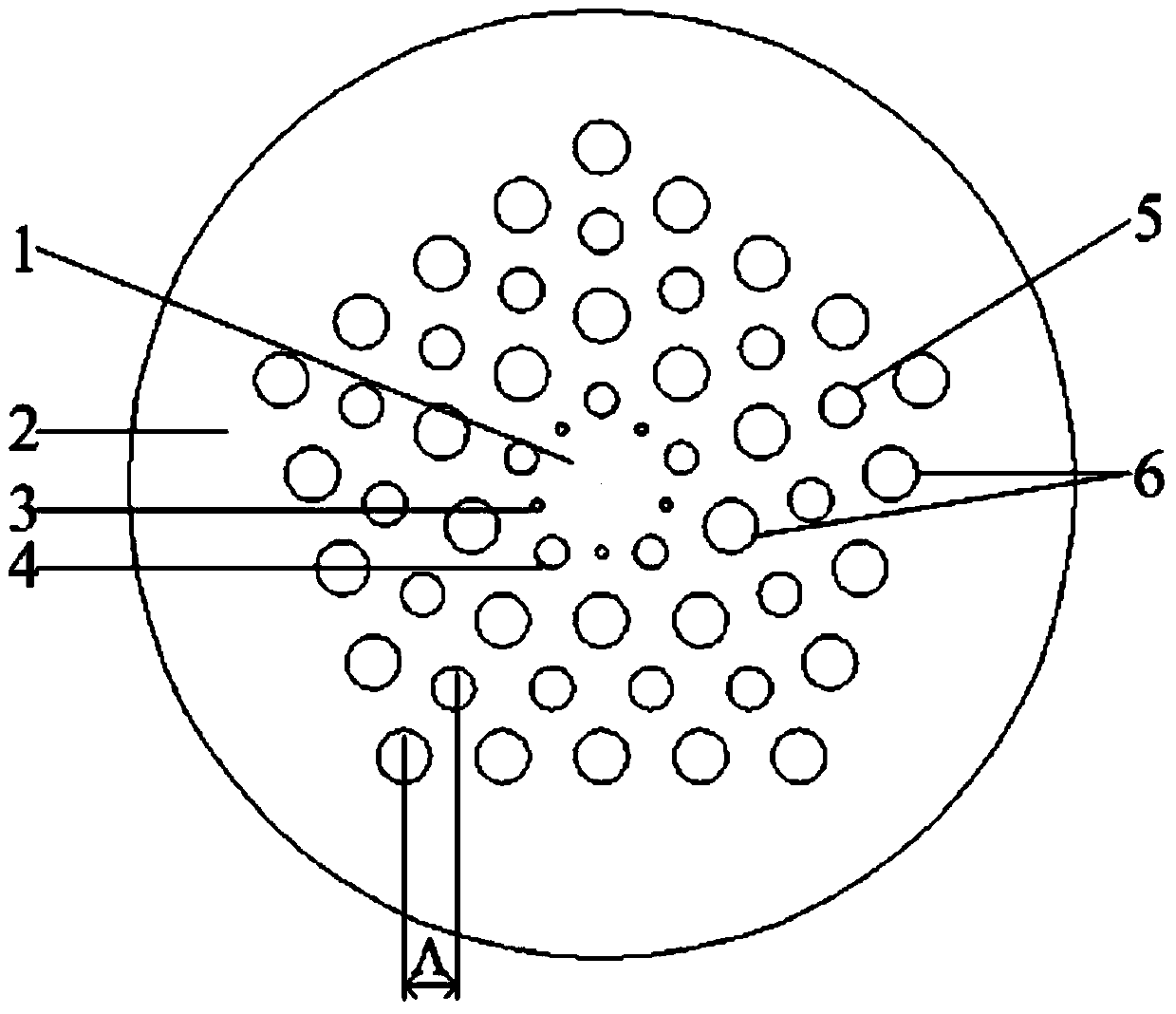

Method used

Image

Examples

Embodiment 1

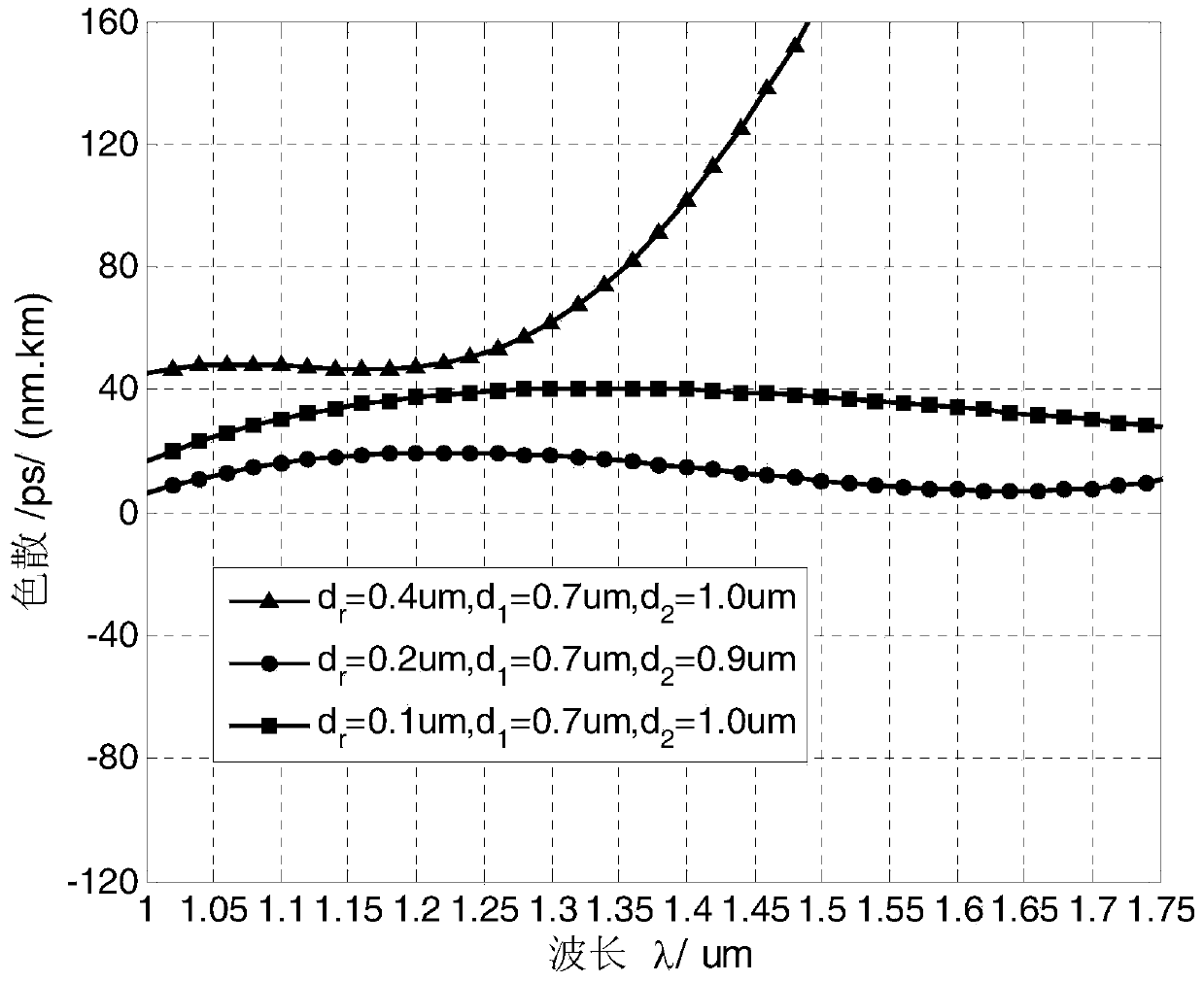

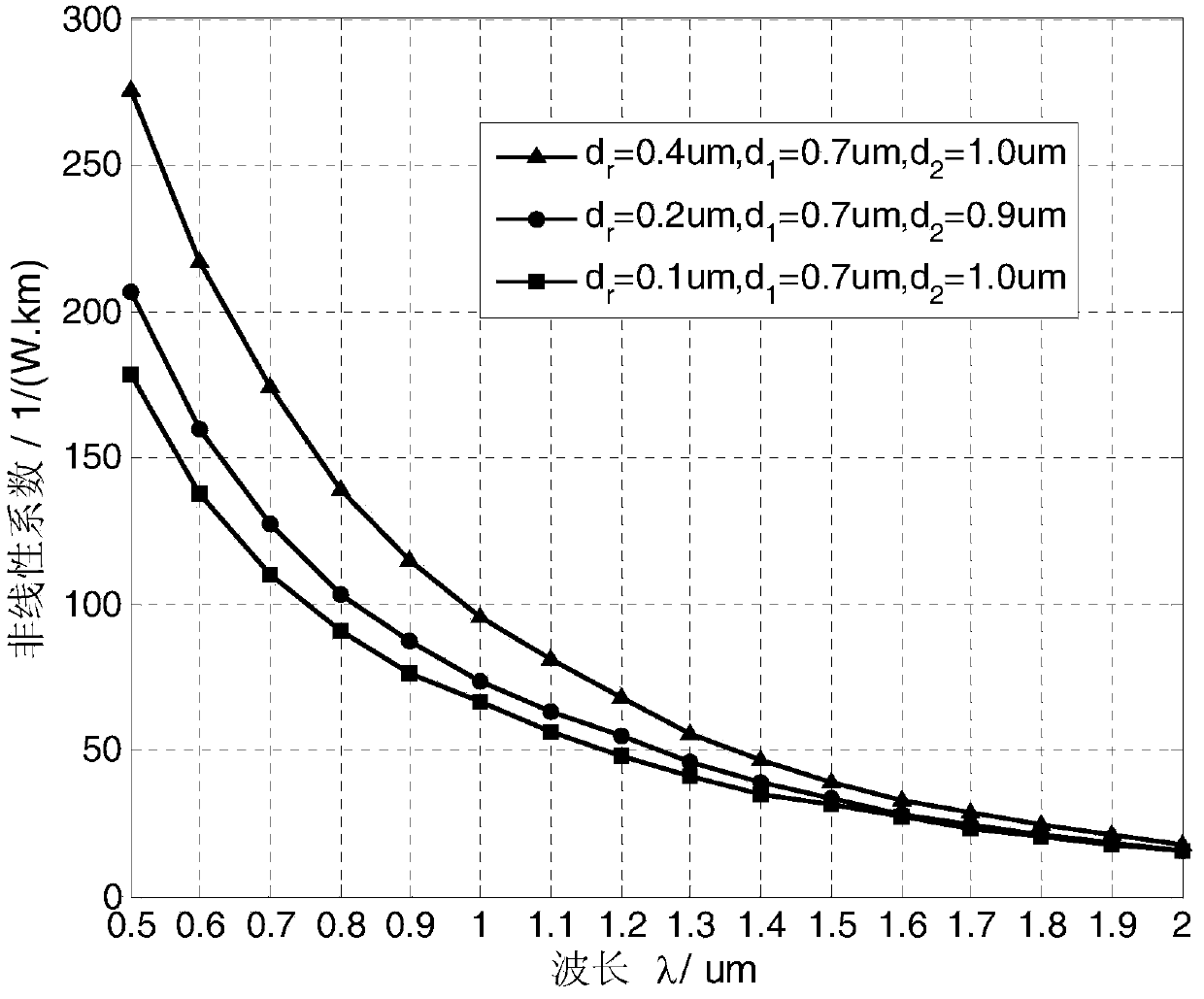

[0023] Example 1: d r =0.4um,d 1 =0.7um,d 2 =1um,d 3 =1um, Λ=1.6um, the dispersion value of embodiment 1 is within the range of 47.5±0.3ps / nm.km within the wavelength of 1.04-1.22um, and has flat dispersion characteristics; within this 180nm bandwidth, the nonlinear coefficient is 70W -1 .km -1 above.

Embodiment 2

[0024] Example 2: d r =0.2um,d 1 =0.7um,d 2 =0.9um,d 3=1um, Λ=1.6um, the dispersion value of embodiment 2 is within the range of 19.5±0.4ps / nm.km within the wavelength of 1.14-1.34um, and has flat dispersion characteristics; within this 200nm bandwidth, the nonlinear coefficient is 45W -1 .km -1 above.

Embodiment 3

[0025] Example 3: d r =0.1um,d 1 =0.7um,d 2 =1um,d 3 =1um, Λ=1.6um, the dispersion value of embodiment 3 is in the range of 36 ± 4ps / nm.km in the wavelength of 1.12-1.64um, and has broadband dispersion flat characteristics; the nonlinear coefficient is 31W in the ultra-wide wavelength range of 520nm -1 .km -1 above.

[0026] figure 2 , image 3 They are respectively the dispersion characteristics and the nonlinear characteristic curves of preferred embodiments 1, 2, and 3. As can be seen from the figure, by optimizing the structural parameters, two kinds of flat characteristics with high nonlinear dispersion at short wavelengths and one with broadband Dispersion-flat photonic crystal fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com