A kind of x-ray tube u target anode and its manufacturing method

An X-ray tube and anode technology, which is applied in the directions of X-ray tube electrodes, X-ray tube parts, cold cathode manufacturing, etc. Easy to oxidize and other problems to achieve the effect of ensuring stability and reliability, small degree of oxidation, and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0034] Example 1 U target anode preparation:

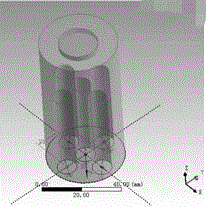

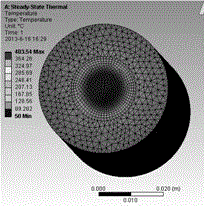

[0035] See figure 1 , using the vacuum induction melting casting process, the metal U is cast into shape, and then it is properly annealed and gradually cooled to room temperature. Then it is machined into a disc shape with a diameter of about 20mm and a thickness of 3mm. Roughness: 0.8;

[0036] Process the high-purity Cu base into a cylindrical sample, and process a cylindrical groove on the upper surface of the Cu base 2 according to the size of the U target, see figure 2 As shown, the roughness of the contact surface with U: 0.8;

[0037] Prepare the sample of U target 1, and then use an automatic polishing machine to polish the upper and lower surfaces to achieve a mirror surface while maintaining the parallelism of the upper and lower surfaces; perform ultrasonic cleaning on U target 1 and Cu base 2 for 20 minutes to remove oil stains, etc., and use alcohol to clean the workpiece wipe dry;

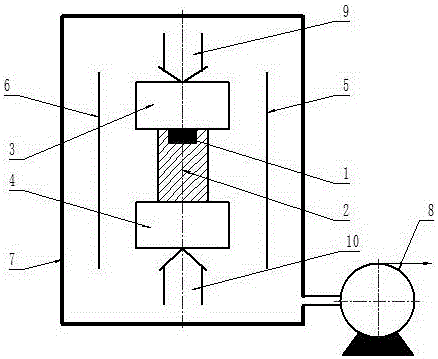

[0038] Put the U target 1 i...

example 2

[0044] Example 2 U target anode preparation:

[0045] See figure 1 , Add the metal U machine into a disc shape, with a diameter of about 20mm and a thickness of 3mm. Roughness: 0.8;

[0046] Process the Cu base into a cylindrical sample, process a cylindrical groove on the upper surface of the Cu base 2 according to the size of the U target, and the roughness of the contact surface with the U: 0.8;

[0047] Prepare the sample of U target 1, polish the upper and lower surfaces to reach the mirror surface, while maintaining the parallelism of the upper and lower surfaces; clean the U target 1 and Cu base 2 to remove oil stains, etc., and dry the workpiece with alcohol;

[0048] Put the U target 1 into the circular groove of the Cu base 2, and then put it into the vacuum diffusion furnace 7 as a whole between the upper indenter 3 and the lower indenter 4, so as to ensure that it is in the center of the finale;

[0049] Close the furnace door and vacuumize to a vacuum degree of 1...

example 3

[0054] Example 3 U target anode preparation:

[0055] See figure 1 , The metal U machine is added into a disc sample, with a diameter of 20mm and a thickness of 3mm. Roughness: 0.8;

[0056] Process the Cu base into a cylindrical sample, process a cylindrical groove on the upper surface of the Cu base 2 according to the size of the U target, and the roughness of the contact surface with the U: 0.8;

[0057] Prepare the sample of U target 1, polish the upper and lower surfaces to reach the mirror surface, while maintaining the parallelism of the upper and lower surfaces; clean the U target 1 and Cu base 2 to remove oil stains, etc., and dry the workpiece with alcohol;

[0058] Put the U target 1 into the circular groove of the Cu base 2, and then put it into the vacuum diffusion furnace 7 as a whole between the upper indenter 3 and the lower indenter 4, so as to ensure that it is in the center of the finale;

[0059] Close the furnace door and vacuumize to a vacuum degree of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com