A kind of foamed aluminum sandwich panel with high specific stiffness and its manufacturing method

A manufacturing method and aluminum foam technology, which is applied in the field of porous metal materials and metal matrix composite materials, can solve the problems of reducing the specific stiffness of aluminum foam, and achieve the effects of low thermal expansion, clean interface, and high specific strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

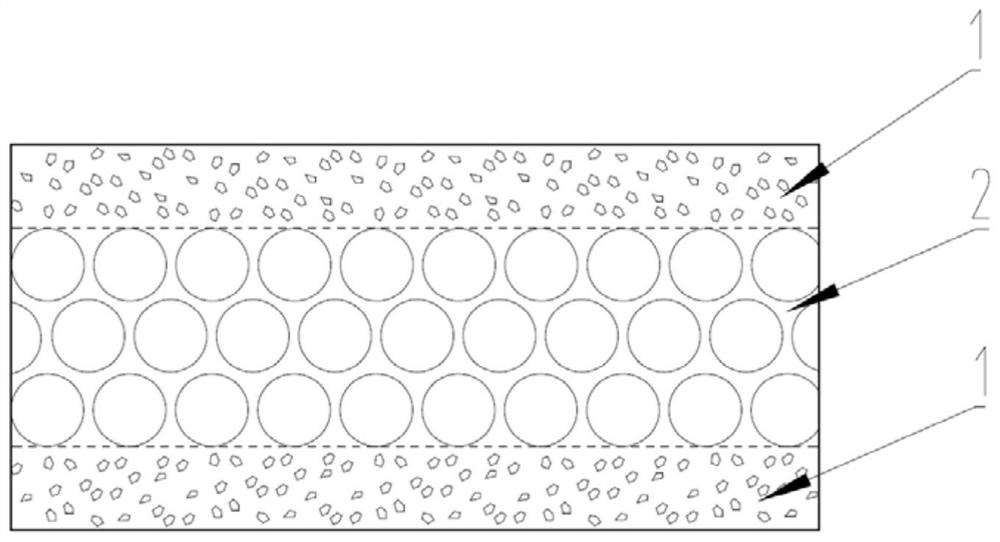

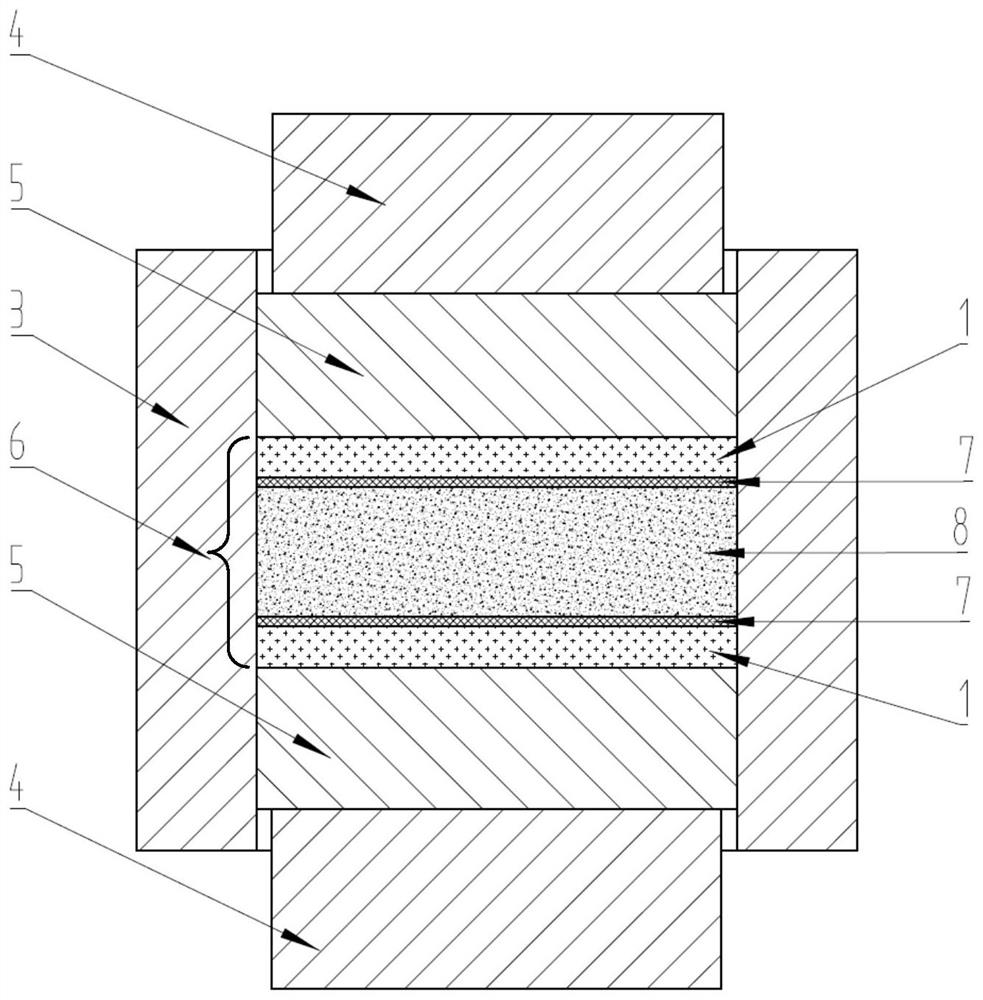

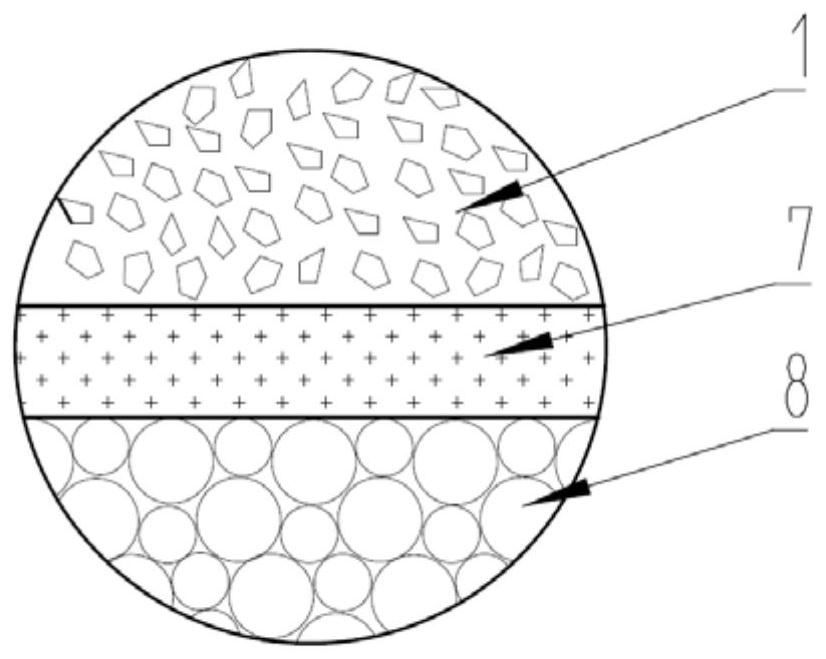

[0055] The process of the total thickness of 10 mm, a panel thickness is 0.5 mm, and the thickness of the foam aluminum core layer is 9 mm is as follows:

[0056] (1) It is called the granularity of 150 destimilation Al-10Si-0.5mg alloy powder 79.5 g (density 2.65 g / cm) 3 0.4 g of titanium hydride powder having a particle size of 325, such that the mass fraction of the aluminum alloy powder and the hydroside powder is 99.5% and 0.5% by weight, respectively, and all loaded into the mixing tank, mixed 8 hours on the mixer, made Mixed powder;

[0057] (2) Select 25% Volsic p The / Al composite is used as a panel material to cut it into a square plate of two 100 mm (long) × 100 mm (width) × 0.5 mm (thick), and the NaOH aqueous solution is cleaned to remove the oxide film, and a copper brush is used to protect the surface. The zinc strip having a thickness of 0.05 mm is selected, and surface treatment is performed using the same method;

[0058] (3) Preparation of steel molds with a ...

Embodiment 2

[0062] The process of the preparation of a total thickness of 25 mm, a panel thickness of 1.25 mm, and the thickness of the foam aluminum core layer of 22.5 mm is as follows:

[0063] (1) It is called the particle size of 150 destimilation Al-10Si-0.5mg alloy powder 199g (density of 2.65 g / cm) 3 1g of the titanium hydride powder of 325 mesh, such that the mass fraction of the aluminum alloy powder and the hydroside powder is 99.5% and 0.5% by weight, respectively, and all loaded into the mixing tank, mixed on the mixer for 8 hours, made into mixing powder;

[0064] (2) Select 10% Volsic p The / Al composite is used as a panel material, and it is cut into two 100 mm (length) × 100 mm (width) × 1.25 mm (thick) square plate, and the NaOH aqueous solution is cleaned to remove the oxide film, and the surface of the copper brush is used. The zinc strip having a thickness of 0.05 mm is selected, and surface treatment is performed using the same method;

[0065] (3) Preparation of steel...

Embodiment 3

[0069] The process of the total thickness of 40 mm, the panel thickness is 2mm, and the thickness of the foam aluminum core layer is 36 mm is as follows:

[0070] (1) Weigh 318g (density of 2.65 g / cm) of Al-11Si alloy powder with a particle size of 150 destination 3 ) powder;

[0071] (2) Select 15% Volsic p The / Al composite material is used as a panel material, and it is cut into two 100 mm (length) × 100 mm (width) × 2 mm (thick) square plate, and the NaOH aqueous solution is cleaned to remove the oxide film, and a copper brush is used to protect the surface. The zinc belt having a thickness of 0.1 mm is selected, and surface treatment is performed using the same method;

[0072](3) Preparation of steel molds with a lumen size of 100 mm (length) × 100 mm (width) × 50mm (high), sequentially load a piece of panel and a zinc strip in the steel mold; then load the mixed powder, the powder is high 12mm, the relative density of powder powder is 60% ± 2%; finally load another zinc ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com