Connection method for carbon fiber composite material and aluminum alloy plate

A technology of aluminum alloy sheet and composite material, which is applied in welding equipment, metal processing equipment, electron beam welding equipment, etc., can solve the problems of difficult connection and poor mechanical properties, so as to improve mechanical properties, remove residual stress, and improve lubrication. wet effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

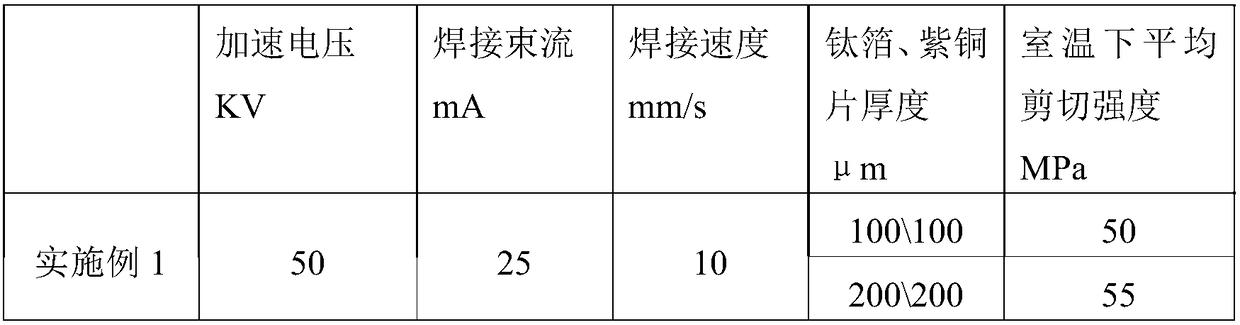

Embodiment 1

[0018] In this embodiment, the carbon fiber reinforced phenolic epoxy composite material T300 / 648 and the 6061 aluminum alloy plate are welded with the dimensions of 100*50*1mm.

[0019] This embodiment includes the following steps:

[0020] S1. Machining the carbon fiber composite material plate and the aluminum alloy plate to obtain the plate to be welded;

[0021] S2. Use 400-mesh sandpaper to polish the contact surfaces of carbon fiber composite material 1, titanium foil 2, copper sheet 3 and aluminum alloy plate 4, and then put them into an acetone solution with a purity ≥ 99.8% for ultrasonic cleaning for 10 to 15 minutes to remove surface oil. and other sundries, make sure the surface is clean;

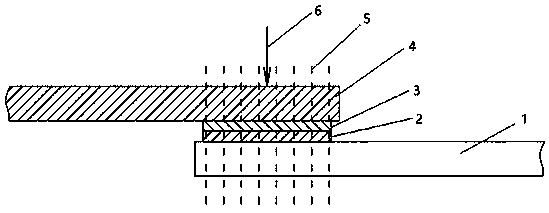

[0022] S3, such as figure 1 As shown, the carbon fiber composite material 1, titanium foil 2, copper sheet 3 and aluminum alloy plate 4 are stacked sequentially from bottom to top. In order to ensure the close contact between each material, a clamp can be used to form an asse...

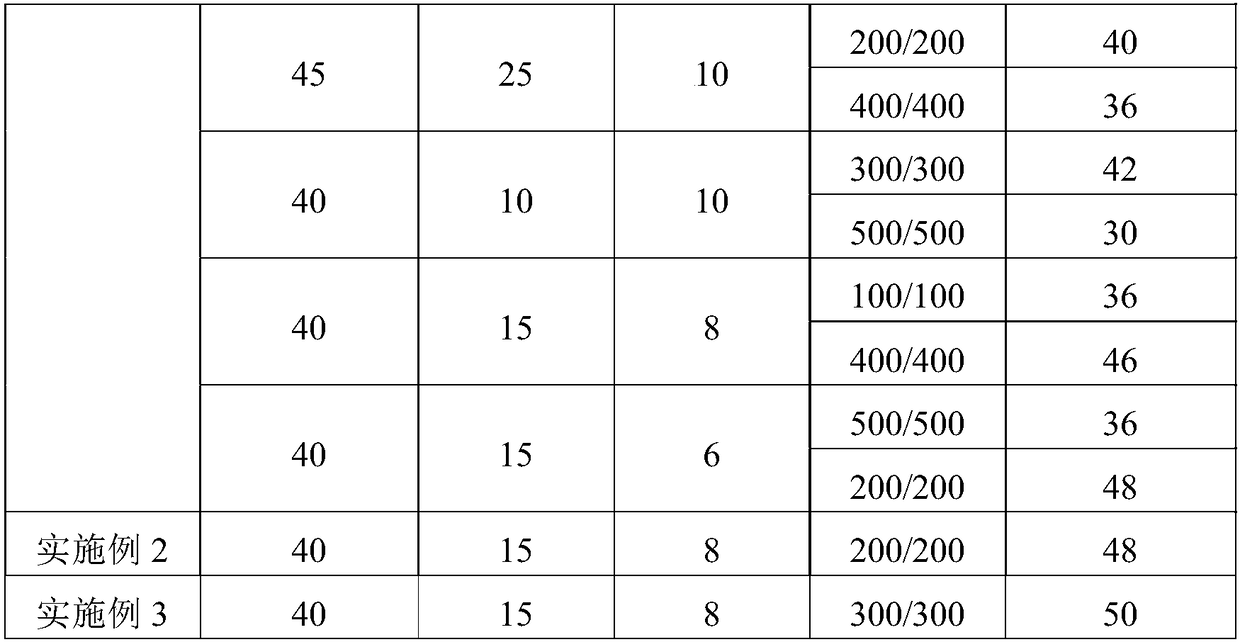

Embodiment 2

[0026] In this embodiment, the carbon fiber reinforced phenolic epoxy composite material T300 / 648 and the 6061 aluminum alloy plate are welded with the dimensions of 100*50*1 mm.

[0027] This embodiment includes the following steps:

[0028] S1. Machining the carbon fiber composite material plate and the aluminum alloy plate to obtain the plate to be welded;

[0029] S2. Use 600-mesh sandpaper to polish the contact surfaces of the carbon fiber composite material, titanium foil, copper sheet and aluminum alloy sheet, and then put it into an acetone solution with a purity ≥ 99.8% for ultrasonic cleaning for 10-15 minutes to remove surface oil and other sundries. Make sure the surface is clean;

[0030] S3. Stack the carbon fiber composite material, titanium foil, copper sheet and aluminum alloy sheet from bottom to top in sequence. In order to ensure the close contact between each material, a clamp can be used to form an assembly;

Embodiment 3

[0034] In this embodiment, the carbon fiber reinforced polyphenylene sulfide plate CF-PPS and the 6061 aluminum alloy plate are welded with the dimensions of 100*50*1 mm.

[0035] This embodiment includes the following steps:

[0036] S1. Machining the carbon fiber composite material plate and the aluminum alloy plate to obtain the plate to be welded;

[0037] S2. Use 1000-mesh sandpaper to polish the contact surfaces of the carbon fiber composite material, titanium foil, copper sheet and aluminum alloy sheet, and then put it into an acetone solution with a purity ≥ 99.8% for ultrasonic cleaning for 10-15 minutes to remove surface oil and other sundries. Make sure the surface is clean;

[0038] S3. Stack the carbon fiber composite material, titanium foil, copper sheet and aluminum alloy sheet from bottom to top in sequence. In order to ensure the close contact between each material, a clamp can be used to form an assembly;

[0039] S4. Carry out electron beam welding with ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com