Power type LED lamp, encapsulation process and reflow soldering process equipment thereof

A LED lamp and reflow soldering technology, which is applied in welding equipment, metal processing equipment, lighting and heating equipment, etc., can solve the problems of high thermal resistance of the connection interface, poor high temperature aging resistance, etc. The effect of poor high temperature aging properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1) if Figure 5 As shown, use a quantitative dispensing machine or a screen printing machine to apply lead-free solder paste 6 on the position where the heat sink needs to be installed on the heat sink seat 3, and then place the chip-heat sink body packaged by low-temperature sintering on the solder paste and apply some pressure to evenly distribute the solder paste between the heat sink and heat sink.

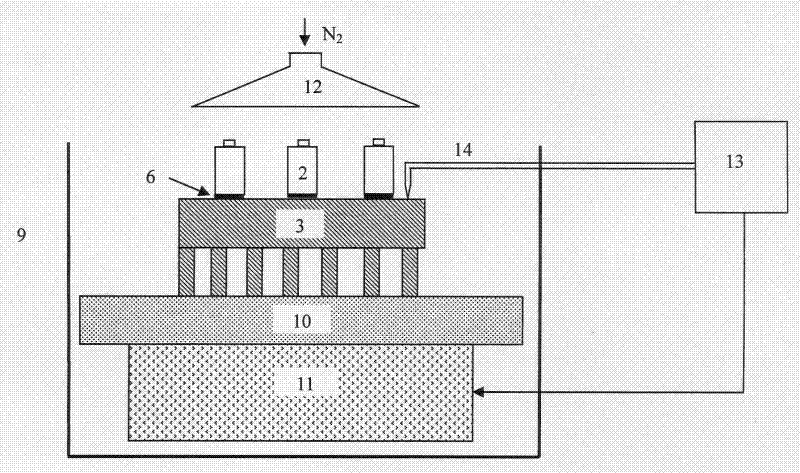

[0040] 2) Put the whole sample into image 3 Reflow soldering is performed in the dedicated reflow oven shown. The equipment is composed of furnace body jacket 9, hot plate 10, resistance heater 11, cooler cover 12, temperature controller 13 and thermocouple 14 and other parts. The lead-free solder paste 6 is pre-coated between the radiator seat 3 and the chip-heat sink body 2 and then placed on the hot plate 10; the thermocouple 14 is fixed on the upper surface of the radiator seat to monitor the temperature of the workpiece surface in real time . The temperature c...

Embodiment 2

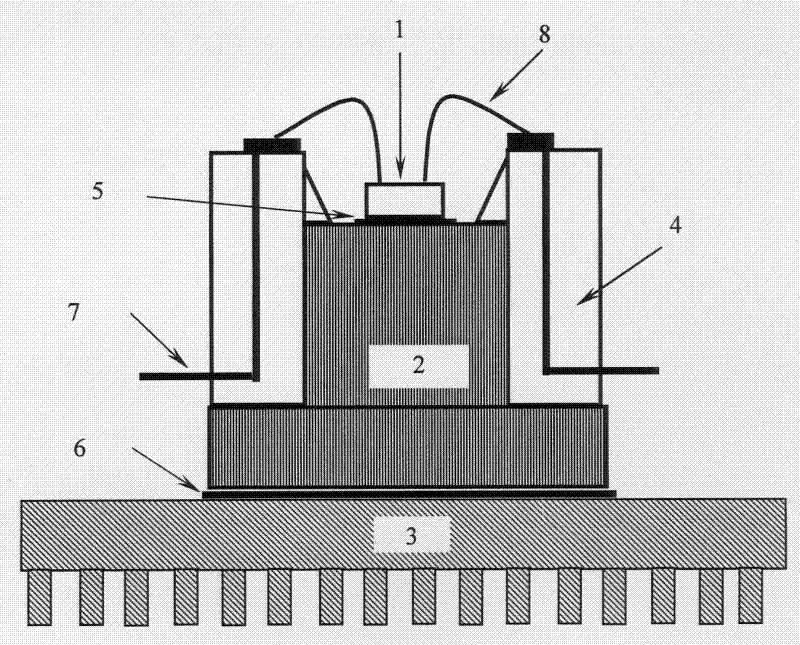

[0044] Embodiment 2: as Figure 4-6 shown.

[0045] First level packaging process:

[0046] 1) if Figure 4 As shown, the prepared nano-silver paste 5 is quantitatively injected on the upper surface of the heat sink 2 by a dispenser, and then the LED chip 1 is placed on the metal paste with vacuum tweezers and pressed tightly, so that the nano-metal paste is placed between the chip and the metal paste. Spread evenly between heat sinks, and control the thickness of the paste layer within the range of 10-40um.

[0047] 2) Put the pre-prepared chip-heat sink body of the nano-metal paste into a vacuum desiccator for 24 hours, so that the organic solvent in the metal paste can be slowly and completely evaporated, and at the same time it will not be in the adhesive layer. The formation of pores affects the quality of subsequent sintering.

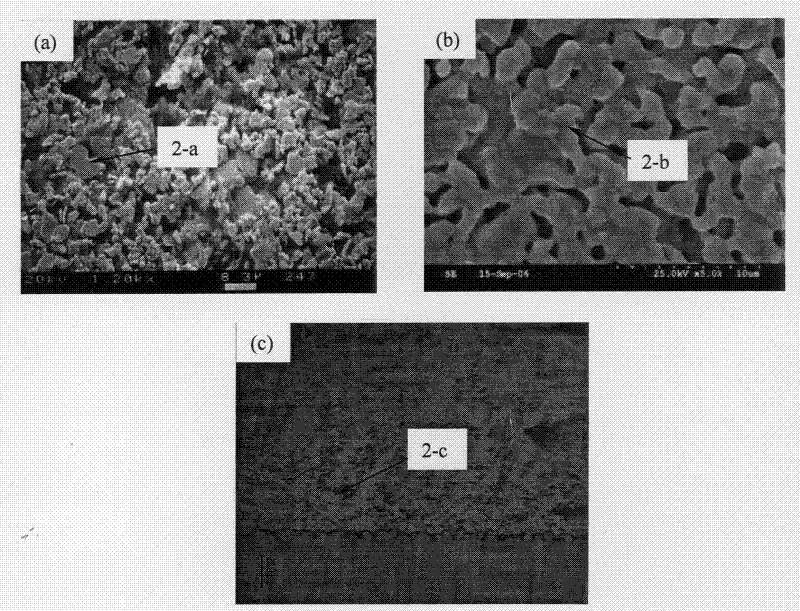

[0048] 3) Put the fully dried chip-heat sink body 2 into a sintering furnace for low-temperature sintering. The specific sintering paramete...

Embodiment 3

[0054] Embodiment 3: as Figure 7 shown.

[0055] 1) The low-temperature sintering process of the chip-heat sink is the same as in Embodiment 1, except for the secondary packaging. Such as Figure 7 As shown, the boss 3-1 required for welding the heat sink is prefabricated on the radiator seat, and the height of the boss is consistent with the thickness of the hollow PCB board to be pasted later. After pasting the hollow PCB circuit board, the upper surface of the boss is on the same plane as the pad on the PCB, and a lead-free solder paste layer is printed on the boss and the corresponding PCB pad with a screen printing machine6 .

[0056]2) Install the reflective cup 4 with the external electrode lead 7 on the chip-heat sink body 2 after the first-level packaging, and then use the gold wire 8 to interconnect with the chip electrode through a wire bonding process.

[0057] 3) Mount the chip-heat sink body with the reflective cup installed on the heat sink seat 3 pre-coate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com