Method for preparing novel magneto-induction degradable nervous tissue engineering material

A technology of nerve tissue and engineering materials, applied in medical science, prostheses, etc., can solve problems such as slowing down the growth rate of nerves, poor functional recovery of innervation areas, poor repairing effect of nerve scaffolds, etc., and achieve the effect of improving the repairing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

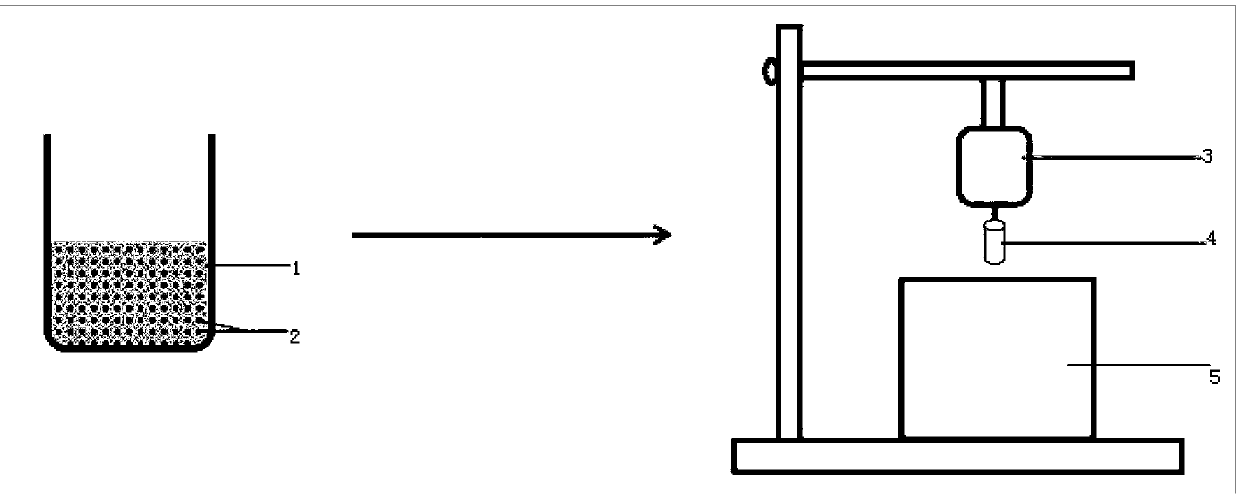

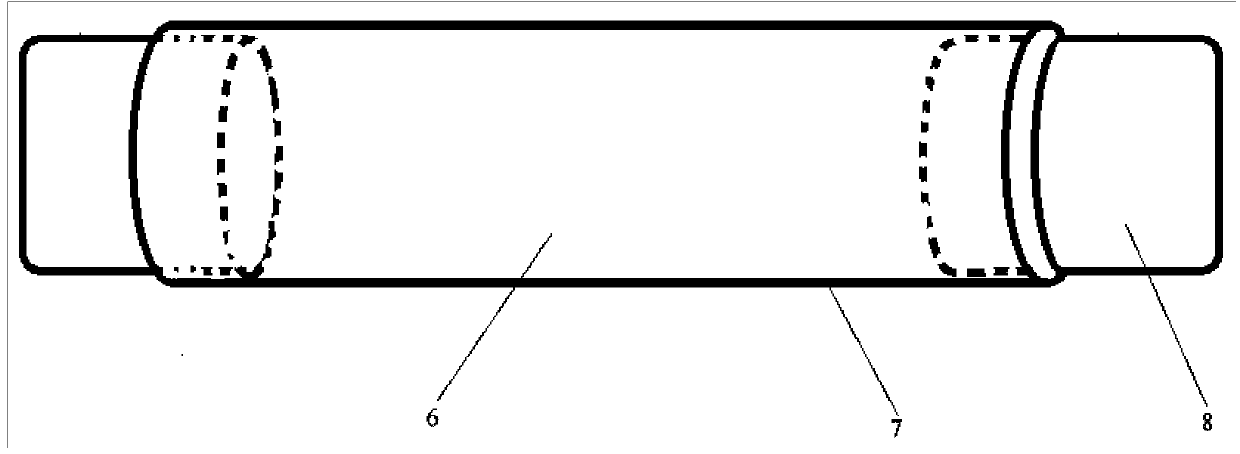

Method used

Image

Examples

Embodiment 1

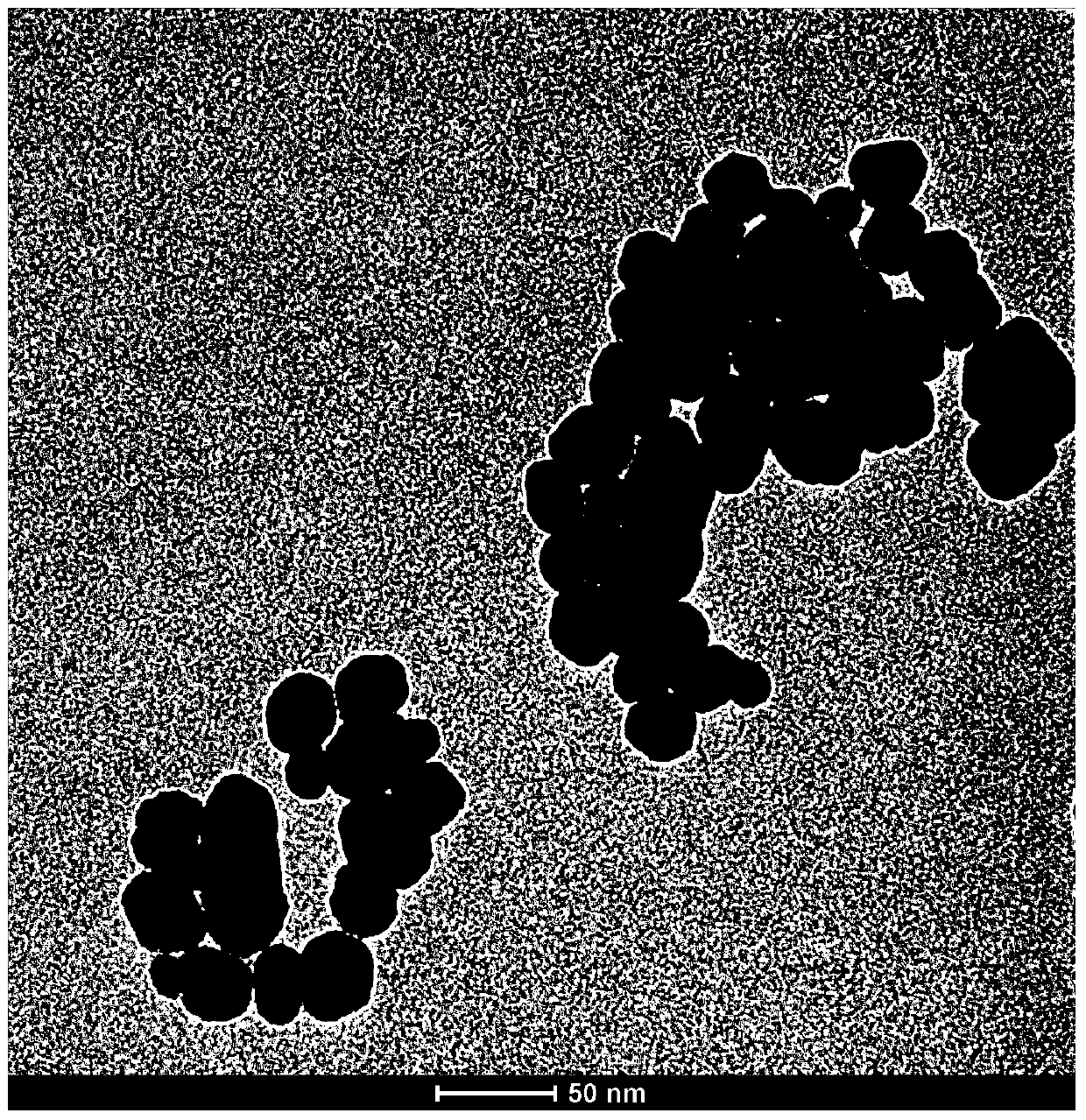

[0029](1) Prepare 0.1mol / L Fe respectively 3+ and Fe 2+ solution, under nitrogen, according to Fe 3+ :Fe 2+ Mix at a molar ratio of 2:1, and mechanically stir for 3 hours to make it fully mixed. Under the condition of continuous nitrogen flow, 1 mol / L NaOH solution was added dropwise to the mixed solution until the pH of the mixed solution was 9, and a black precipitate was obtained. Then the water bath was heated for 2h, and then after standing for 5h, the supernatant was removed, the generated particles were filtered under reduced pressure, washed repeatedly with distilled water and absolute ethanol, and the impurity ions on the surface of the particles were washed away, and the obtained particles were obtained at 50 °C, vacuum-dried, ground and sieved to obtain MNPs.

[0030] (2) Weigh chitosan and sodium β-glycerophosphate respectively, the masses of chitosan and sodium β-glycerophosphate are 50 mg and 5 mg respectively, and weigh 5 mg of MNPs prepared in (1).

[0031...

Embodiment 2

[0036] (1) Prepare 0.1mol / L Fe respectively 3+ and Fe 2+ solution, under nitrogen, according to Fe 3+ :Fe 2+ Mix at a molar ratio of 2:1, and stir mechanically for 3.5 hours to make it fully mixed. Under the condition of continuous nitrogen flow, 1 mol / L NaOH solution was added dropwise to the mixed solution until the pH of the mixed solution was 9.5, and a black precipitate was obtained. Then the water bath was heated for 2h, and then after standing for 5h, the supernatant was removed, the generated particles were filtered under reduced pressure, washed repeatedly with distilled water and absolute ethanol, and the impurity ions on the surface of the particles were washed away, and the obtained particles were obtained at 50 °C, vacuum-dried, ground and sieved to obtain MNPs.

[0037] (2) Weigh chitosan and sodium β-glycerophosphate respectively, the masses of chitosan and sodium β-glycerophosphate are 50 mg and 5 mg respectively, and weigh 10 mg of MNPs prepared in (1).

...

Embodiment 3

[0043] (1) Prepare 0.1mol / L Fe respectively 3+ and Fe 2+ solution, under nitrogen, according to Fe 3+ :Fe 2+ Mix at a molar ratio of 2:1, and mechanically stir for 4 hours to make it fully mixed. Under the condition of continuous nitrogen flow, 1 mol / L NaOH solution was added dropwise to the mixed solution until the pH of the mixed solution was 10, and a black precipitate was obtained. Then the water bath was heated for 2h, and then after standing for 5h, the supernatant was removed, the generated particles were filtered under reduced pressure, washed repeatedly with distilled water and absolute ethanol, and the impurity ions on the surface of the particles were washed away, and the obtained particles were obtained at 50 °C, vacuum-dried, ground and sieved to obtain MNPs.

[0044] (2) Weigh chitosan and sodium β-glycerophosphate respectively, the masses of chitosan and sodium β-glycerophosphate are 50 mg and 5 mg respectively, and weigh 20 mg of MNPs prepared in (1).

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com