Cosmetic overlaying material for composite overlaying remanufacturing of support roller and preparation method for cosmetic overlaying material

A technology of surfacing materials and back-up rolls, applied in the field of surfacing, can solve problems such as huge stress, affecting steel rolling production, cold work hardening, etc., achieve excellent crack resistance and plastic toughness, reduce roll consumption costs, and improve plastic toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

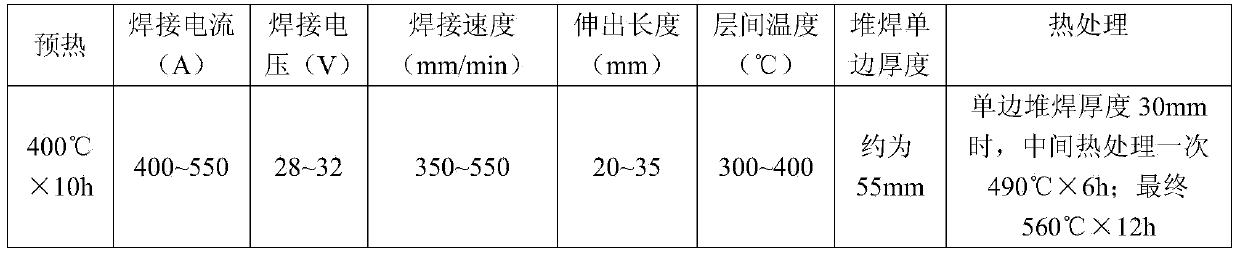

Method used

Image

Examples

Embodiment 1~4

[0026] The cover surfacing materials were prepared respectively according to the composition of each cover surfacing material shown in Table 1. The preparation method is:

[0027] (1) After converting according to the ratio shown in Table 1, select the corresponding compound or alloy powder, and mix it uniformly in a powder mixer in proportion to obtain the covering material powder;

[0028] (2) Slitting the cold-rolled steel strip with a thickness of 0.3mm to 1.0mm into a steel strip with a width of 8mm to 16mm by a slitting machine, and rolling the steel strip into a U-shaped cross section on the wire rolling machine, and the U-shaped steel strip. Fill the mixed cap surface material powder into the groove, and then roll the steel strip into a welding wire blank tube with an O-shaped cross section of Φ3mm~5mm;

[0029] (3) Use a multi-connected linear wire drawing machine to draw the welding wire blank tube to the finished welding wire with a size of Φ1.6mm-4.0mm, and then u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com