Conjugated polymer, preparation method and applications thereof

A technology of conjugated polymers and compounds, used in chemical instruments and methods, semiconductor/solid-state device manufacturing, organic chemistry, etc., can solve problems such as low photoelectric conversion efficiency, and achieve the effect of increasing the light absorption range and reducing the energy gap.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation method of above-mentioned conjugated polymer comprises the following steps:

[0045] a) provide the following compounds A and B;

[0046] Compound A is

[0047] Compound B is

[0048] b) Under an inert gas atmosphere, add the compound A and the compound B into an organic solvent at a molar ratio of 1:1.1-1.5, add a catalyst after dissolving, and then carry out a Stille coupling reaction at 60-120°C for 24- 72 hours, separated and purified to obtain the conjugated polymer (P);

[0049]

[0050] Among them, R 1 for C 1 ~C 16 the alkyl group, R 2 for C 1 ~C 16 the alkyl group, R 3 , R 4 H or C respectively 1 ~C 12 Alkyl group, n is a natural number between 5 and 60.

[0051] Described catalyst can be tetrakis (triphenylphosphine) palladium (Pd (PPh 3 ) 4 ) or bis(triphenylphosphine)palladium dichloride (Pd(PPh 3 ) 2 Cl 2 );or

[0052] The catalyst can also be a mixture of organic palladium and organic phosphine ligands, the molar r...

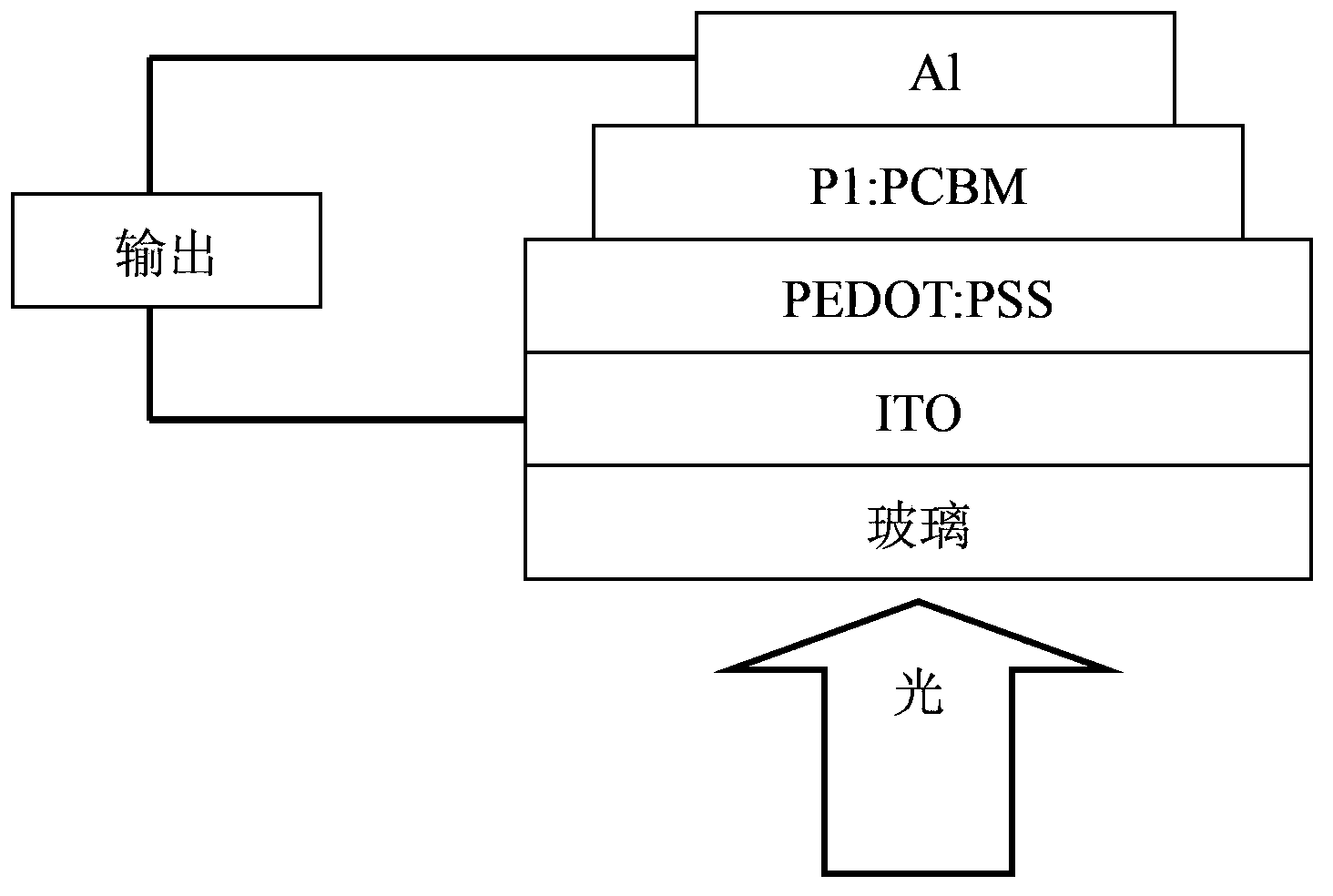

Embodiment 1

[0070] The conjugated polymer disclosed in this example is specifically compound P1, and its structural formula is as follows:

[0071] n=5;

[0072] 1. Preparation of compound A1

[0073] 1) Synthesis of 2,2'-(2,5-dibromo-1,4-phenyl)bis(3-bromothiophene)

[0074]

[0075] Under nitrogen protection, 2.54g (60mmol) lithium chloride, 4.8g (10mmol) 2,5-dibromo-1,4-diiodobenzene (a), 287.5mg (0.25mmol) Pd were successively added to the reaction flask (PPh 3 ) 4 , 5g (50mmol) cuprous chloride, 3.59g (11mmol) 3-bromo-2-trimethyltinthiophene (b), 60ml tetrahydrofuran. After the reactant was stirred at room temperature for 1 h, the temperature was raised to 50° C. for 3 h. After cooling to room temperature, the solid produced by the reaction was filtered to obtain the crude product c, namely 2,2'-(2,5-dibromo-1,4-phenyl)bis(3-bromothiophene), with a yield of 40% , MS (EI) m / z: 558 (M + );

[0076] 2) Synthesis of compound d1

[0077]

[0078] Under argon protection, 5...

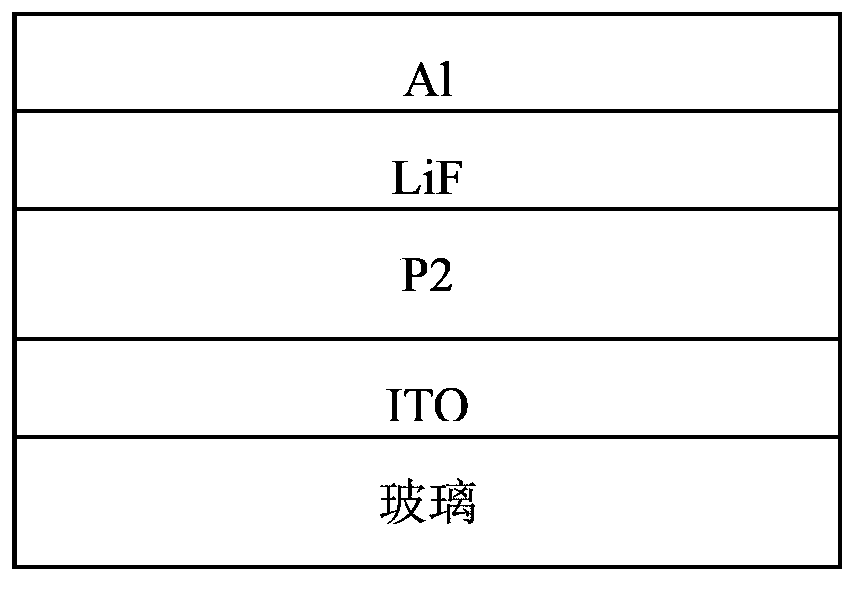

Embodiment 2

[0087] The conjugated polymer disclosed in this example is specifically compound P2, and its structural formula is as follows:

[0088] n=60;

[0089] One, the preparation of compound A2:

[0090] 1) Synthesis of 2,2'-(2,5-dibromo-1,4-phenyl)bis(3-bromothiophene)

[0091] Under nitrogen protection, 2.63g (62mmol) lithium chloride, 4.8g (10mmol) 2,5-dibromo-1,4-diiodobenzene (a), 0.7mg (0.001mmol) Pd were successively added to the reaction flask (PPh 3 ) 2 Cl 2 , 5.15g (52mmol) cuprous chloride, 4.89g (15mmol) 3-bromo-2-trimethyltinthiophene (b), 60ml DMF. The reactant was stirred at room temperature for 2 h, and then heated to 55° C. for 4 h. After cooling to room temperature, the solid produced by the reaction was filtered to obtain the crude product c, namely 2,2'-(2,5-dibromo-1,4-phenyl)bis(3-bromothiophene), with a yield of 39% , MS (EI) m / z: 558 (M + ); (see Example 1 for the reaction formula)

[0092] 2) Synthesis of compound d2

[0093]

[0094] Under nit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com